Steam fabric setting machine cascade waste heat comprehensive utilization system of printing and dyeing mill

A technology of setting machine and printing and dyeing factory, which is applied in the direction of steam generation, lighting and heating equipment, and equipment configuration for processing textile materials. Utilization efficiency, reduction of energy consumption, and effects of solving power shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

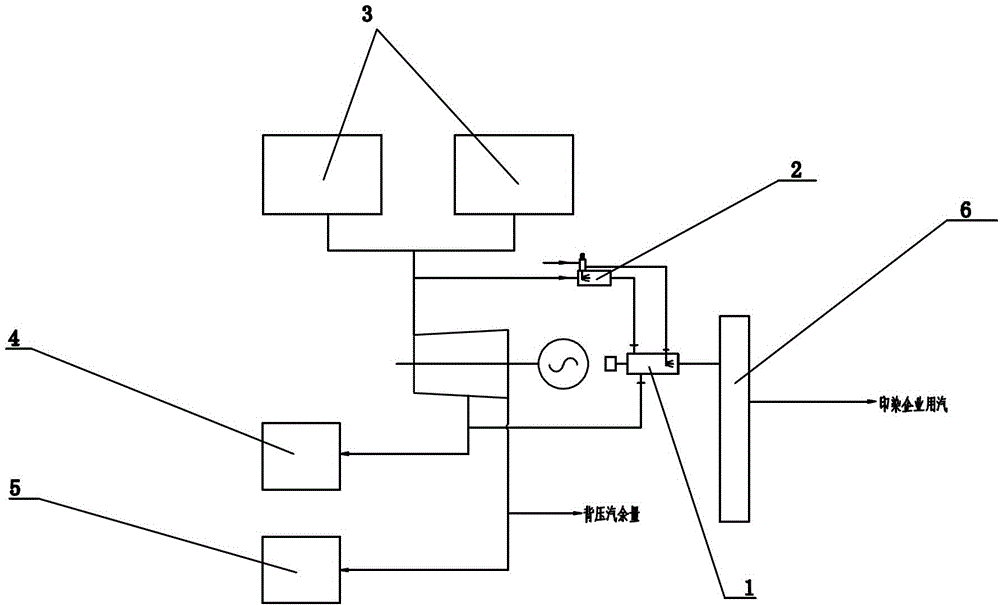

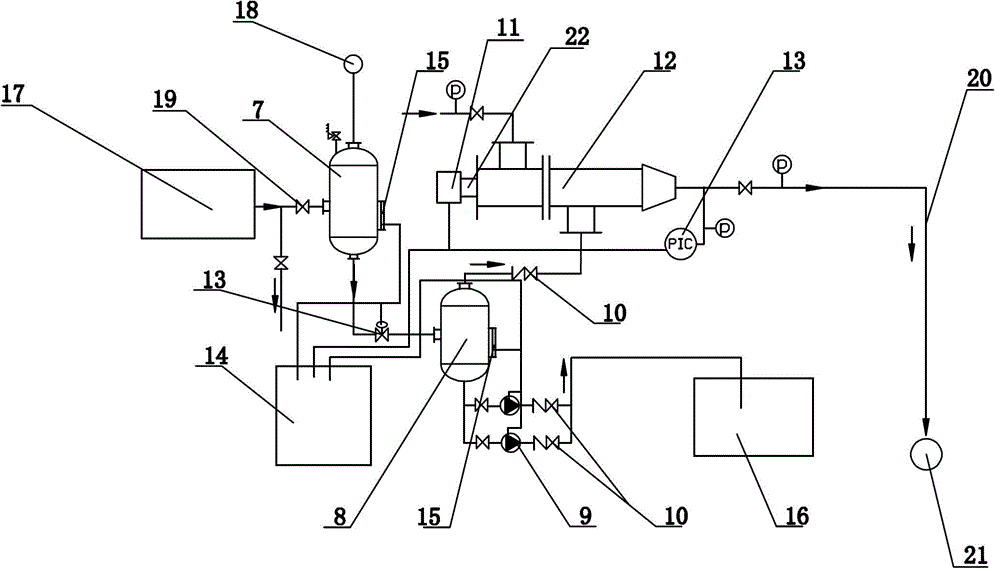

[0023] Such as figure 1 and figure 2 As shown, the cascade waste heat comprehensive utilization system of the steam fabric setting machine in the printing and dyeing factory of the present invention includes a heat setting machine condensed water exhaust steam two-stage flash thermal system connected with the pressure matching system, and a heat setting machine condensed water exhaust steam two-stage flash evaporation The thermal system includes heat setting machine condensed water collection device 17, control device, multi-stage flash evaporation device, electric actuator 11 and high temperature anti-cavitation water pump 9, heat setting machine condensed water collection device 17 is connected with multi-stage flash evaporation through pipelines Device; the multi-stage flash device is respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com