Oil pump leading cable for offshore petroleum platform

A technology for offshore oil and oil platforms, applied in the direction of insulating cables, cables, circuits, etc., to achieve the effects of small size, good electrical performance, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

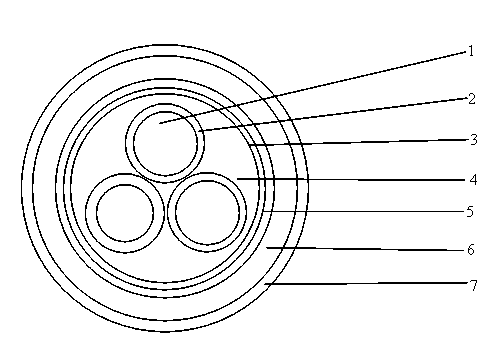

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] An oil pump lead cable for an offshore oil platform, comprising a conductor 1 and an insulating layer 2, and the cross-sectional area of the conductor 1 is 10-25 mm 2 , the outside of the conductor 1 is respectively wrapped with an insulating layer 2, and after wrapping the insulating layer 2, the conductors 1 are mutually twisted into bundles, and the outer side of the insulating layer 2 is wrapped with a tape layer 3 after being bundled, and a barrier is provided between the tape layer 3 and the insulating layer 2 Combustible glass fiber rope is used as the filling layer 4, and the outside of the tape layer 3 is wrapped with a high flame-retardant and oil-resistant chloroprene rubber lining layer 5, and the outside of the lining layer 5 is wrapped with a galvanized steel wire armor layer 6, and the armor layer The outside of layer 6 is covered with a high fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com