Driver of stepping motor

A stepping motor and driver technology, applied in the direction of motor generator control, electrical components, control systems, etc., to achieve the effects of reduced rotation noise, stable rotation, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

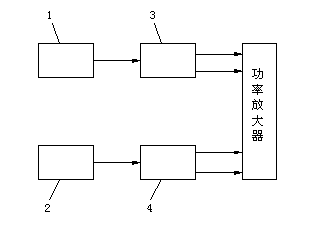

[0018] The stepper motor driver of the present invention includes a power amplifier for driving the stepper motor, and a signal generator for outputting control signals to the power amplifier.

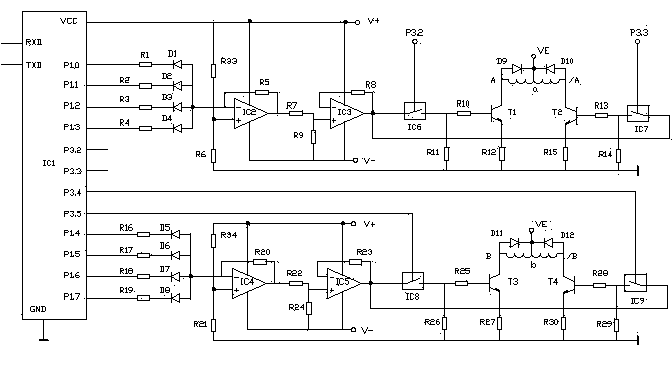

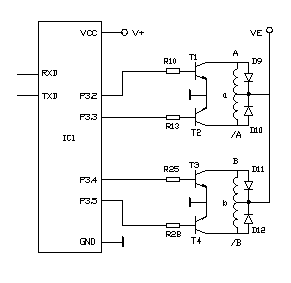

[0019] The power amplifier converts the voltage delivered by the signal generator into a current in a certain ratio, so that the windings of the stepping motor generate a magnetic field. , b terminals A, / A, B, / B are connected, the center taps of the stepper motor windings a and b are connected to the power supply VE, and the collectors of the transistors T1-T4 are respectively connected to the power supply VE for freewheeling. The diodes D9-D12, the bases of the triodes T1-T4 are respectively connected to the output terminals of the analog switches IC6, IC7, IC8 and IC9 through the resistors R10, R13, R25 and R28, and the emitters of the triodes T1-T4 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com