PTC heating piece heating flue-cured tobacco type electronic cigarette

A heating sheet and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of large FPC temperature fluctuations and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

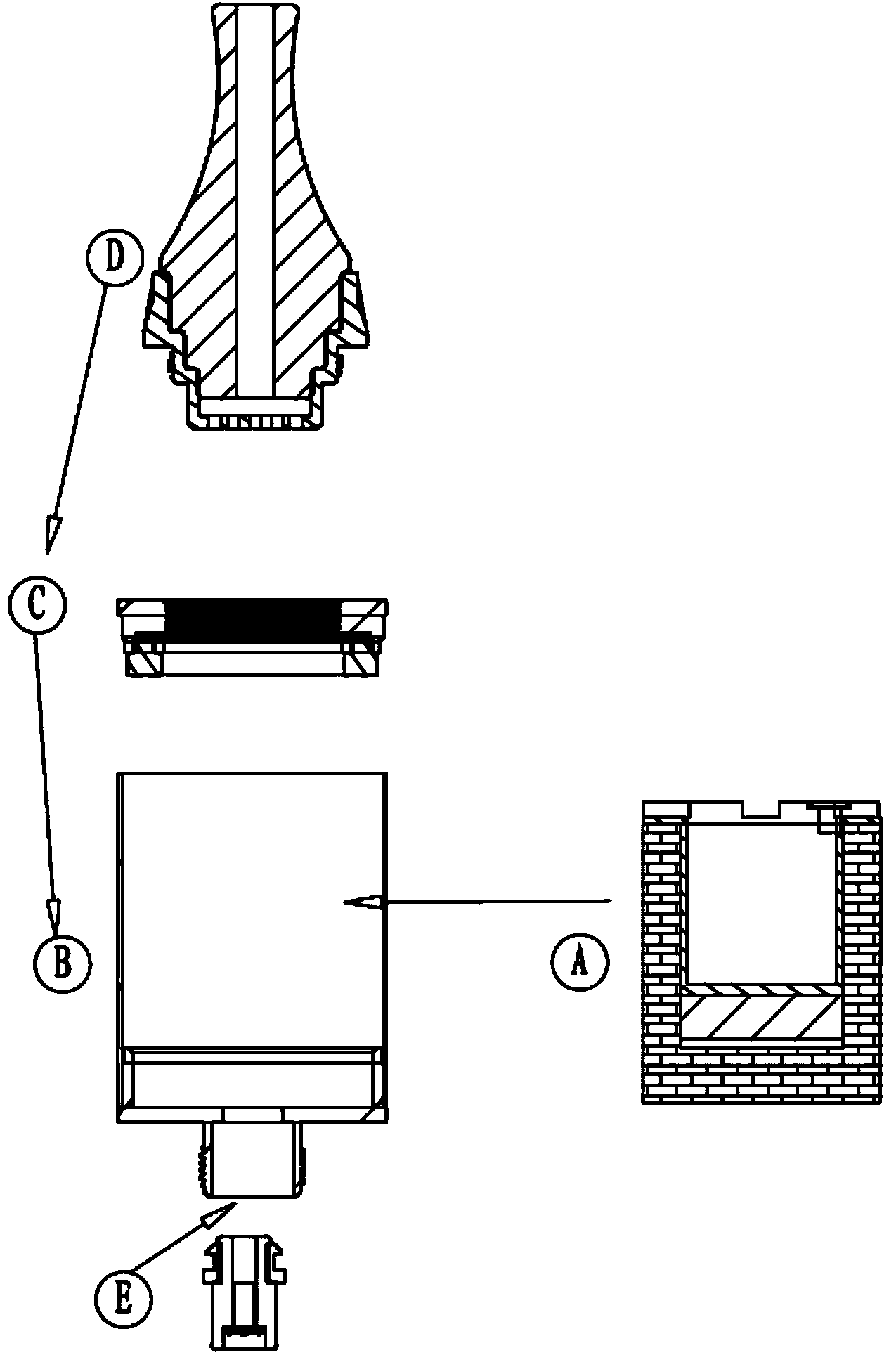

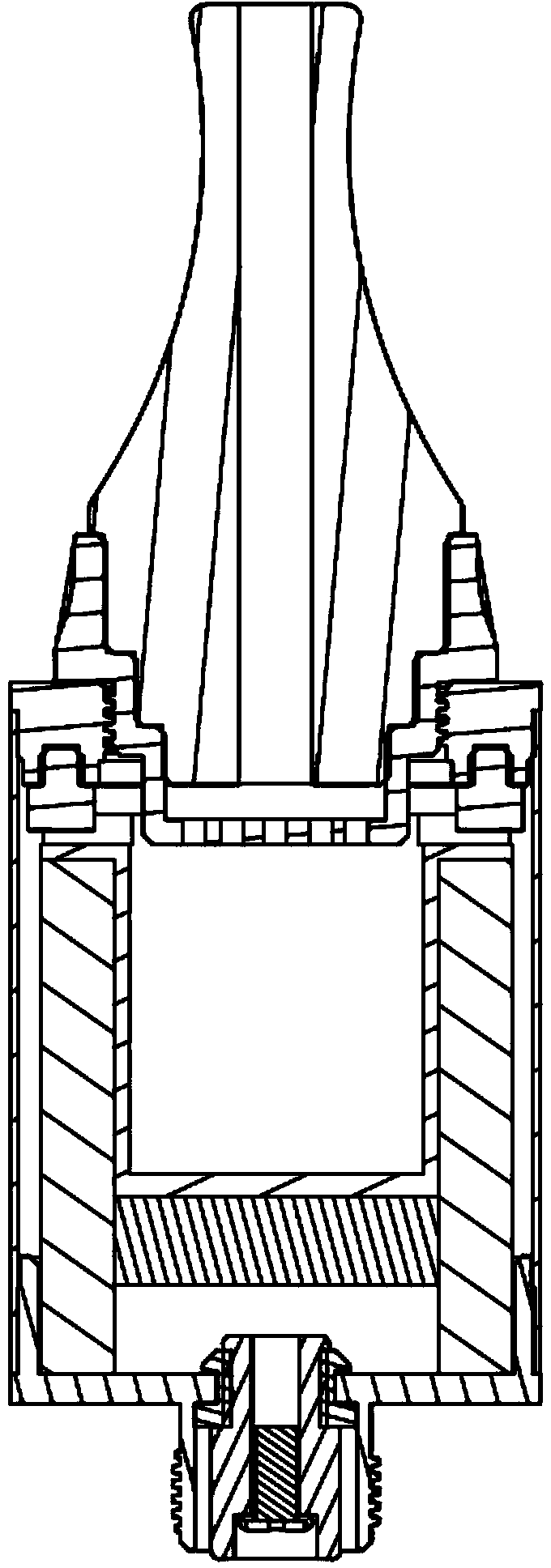

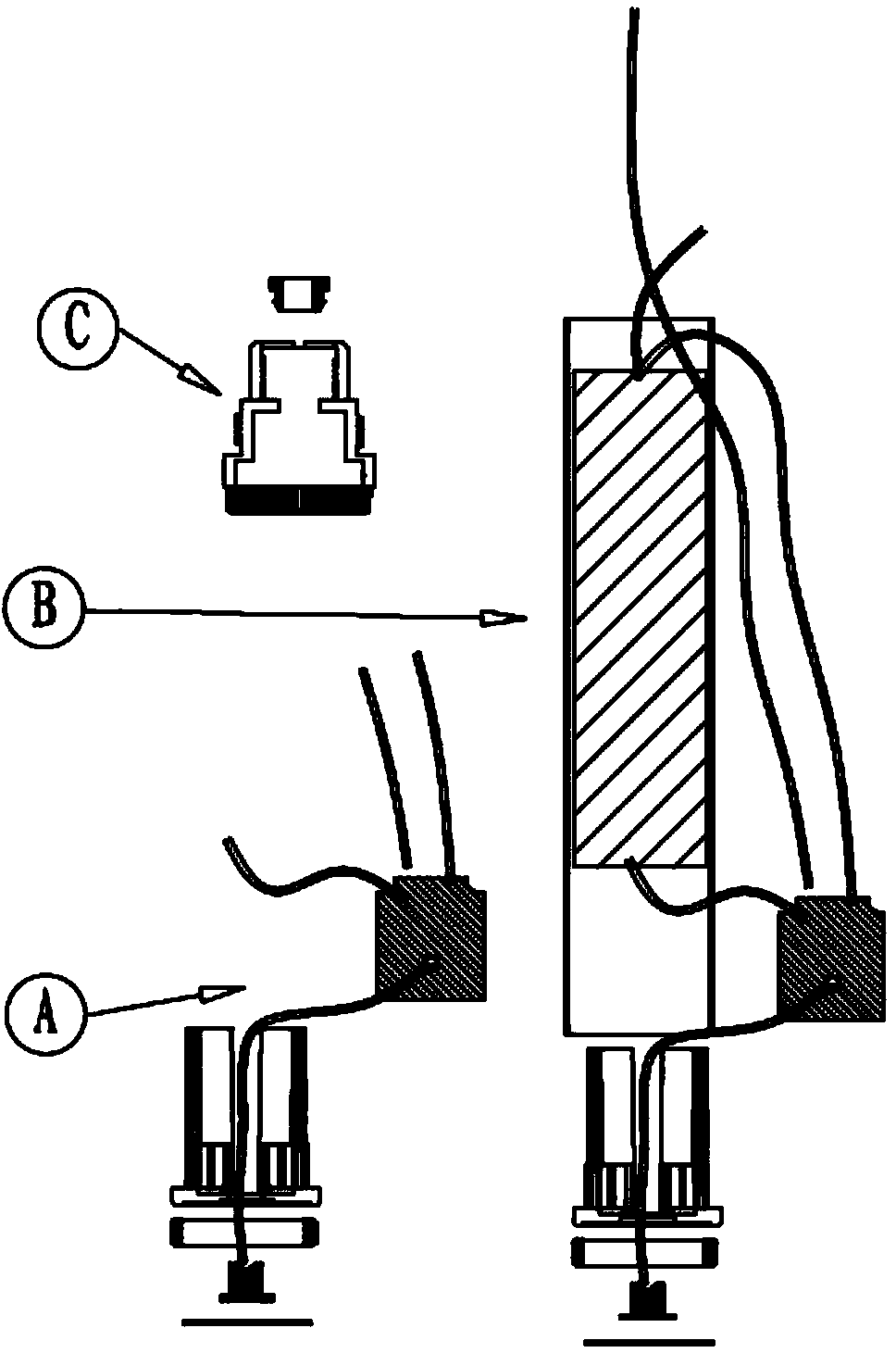

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The present invention adopts PTC heating sheet to generate heat instead of conventional resistance wire. This PTC heating sheet heating flue-cured tobacco electronic cigarette changes PTC heating sheet to 3.7V lithium battery for power supply, and the heating speed can reach the same speed as that of mains power supply. There are several difficulties in achieving this effect: the resistance of the PTC heating element must be changed to a sufficiently small value, which is limited by the material of the PTC heating element itself. If you want to lower the resistance, you must make the material thinner. Through research, in order to achieve the ideal heating effect, the PTC heating sheet should be 3 ohms, and the corresponding PTC heating sheet material thickness should be 0.3 mm. Because the material needs to be thinner, it will affect the process of PTC heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com