Stabilization chemical agent and processing method for processing nickel-containing dead catalyst

A technology of waste catalyst and treatment method, applied in the direction of protection device against harmful chemical agents, etc., can solve problems such as environmental pollution, and achieve the effect of good stabilization effect, cost reduction, direct material cost and landfill cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

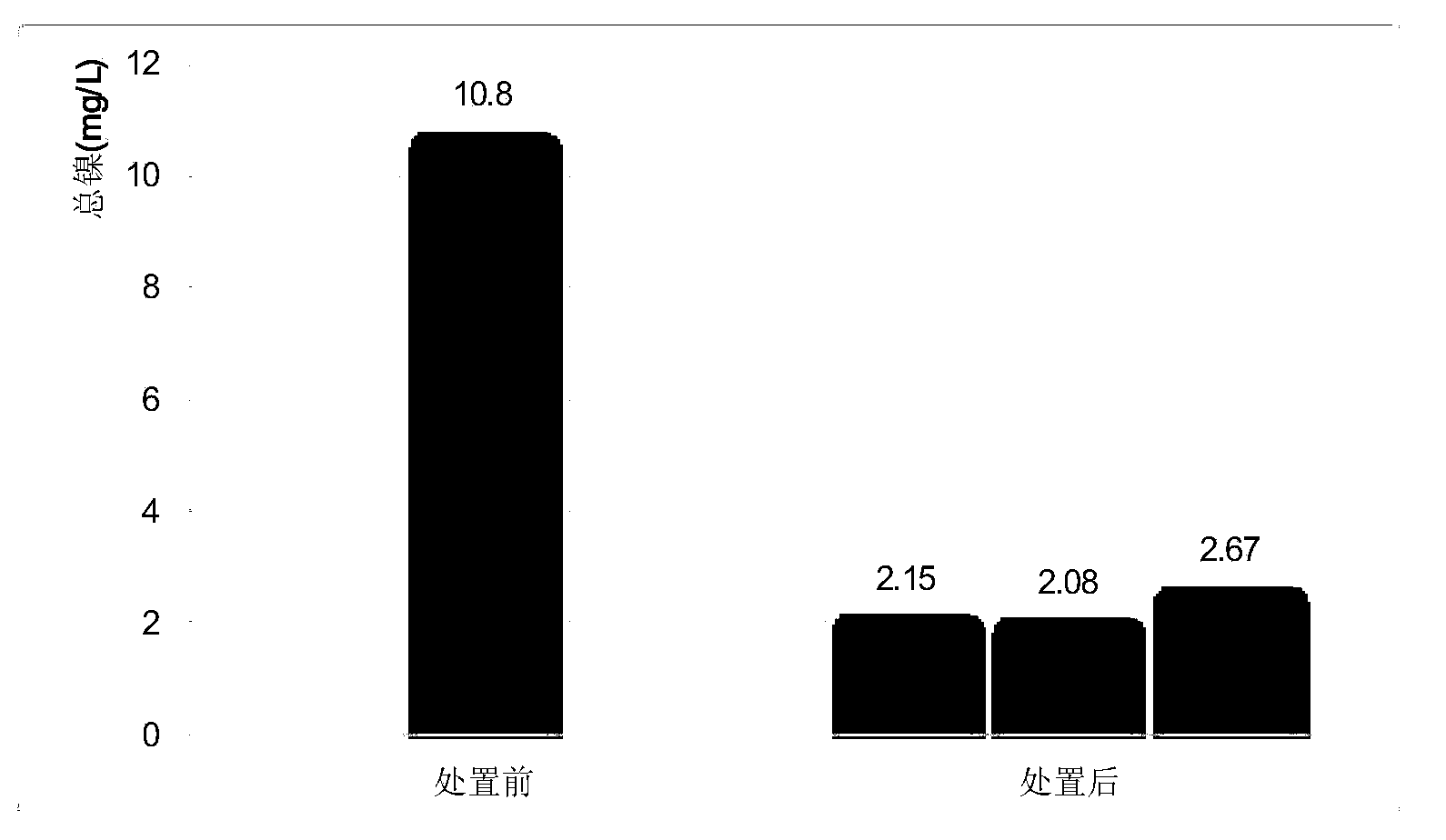

[0033] The processing of embodiment 1 nickel-containing waste catalyst

[0034] First, a stabilizing agent composed of artificial zeolite and potassium ethyl xanthate at a mass ratio of 15-25:1 is used.

[0035] Then, process the nickel-containing waste catalyst according to the following steps: first step, weigh the nickel-containing waste catalyst with a belt scale and put it into the feeding hopper; follow-up steps determine the dosage of the agent accordingly.

[0036] The second step, if the spent nickel-containing catalyst is in the form of uniform fine particles, proceed to the next step directly; if the spent nickel-containing catalyst is in the form of non-uniform, first process the spent nickel-containing catalyst to be in the form of uniform fine particles before proceeding to the next step ( This treatment can be crushing, sieving, vibration crushing and other existing technical means); this can ensure that the stabilizing agent can fully contact and react with the...

Embodiment 2 Embodiment 1

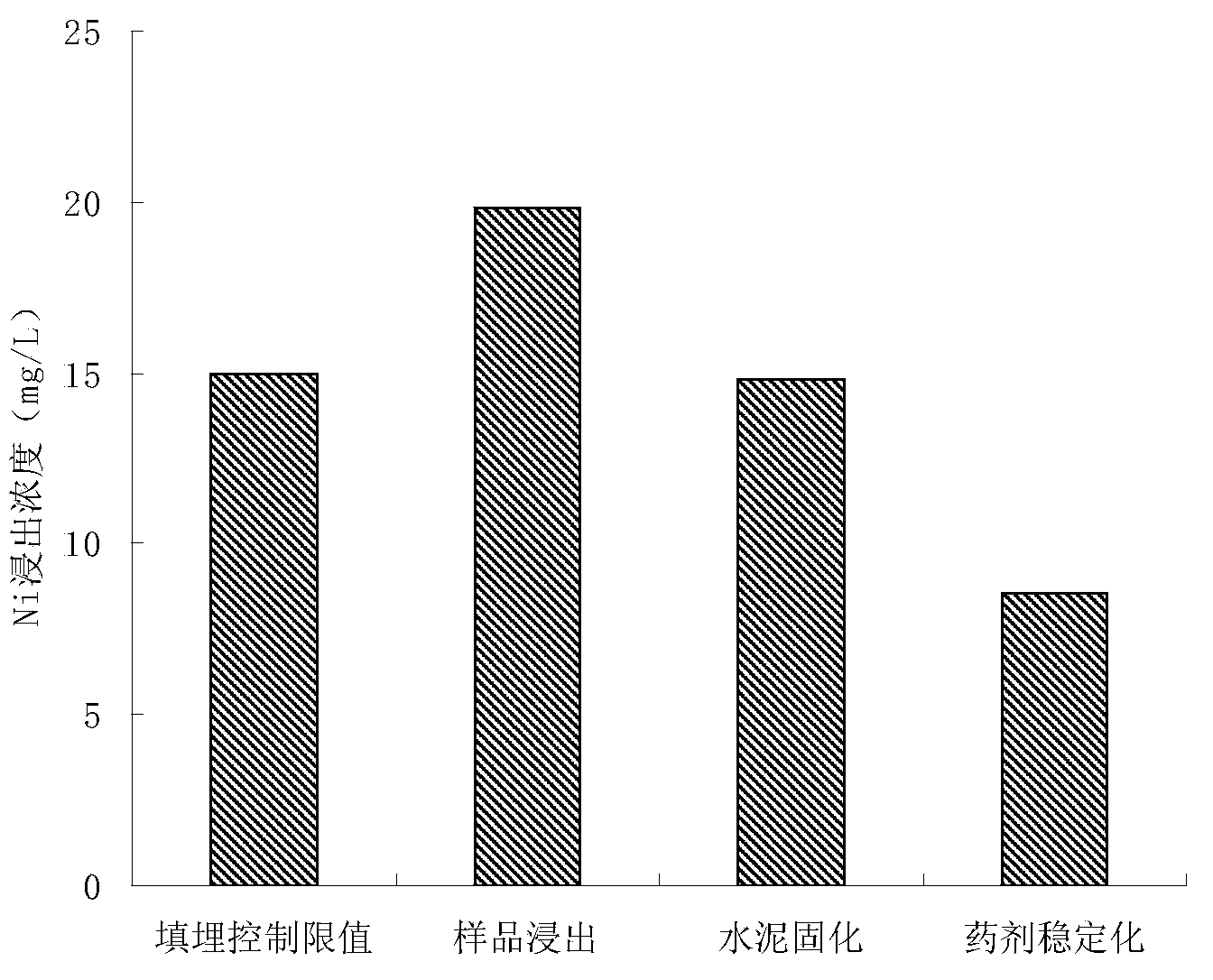

[0044] The comparison of embodiment 2 embodiment 1 method and traditional cement curing method

[0045] The same batch of nickel-containing waste catalysts is processed by the method of embodiment 1 and the traditional cement solidification method respectively, and the nickel leaching concentration and the nickel leaching concentration of the products obtained by each method are detected according to the method specified in the national standard GB18598-2001 "Hazardous Waste Landfill Control Standard", and The nickel leaching concentration of each method gained product in pH2-12, the result is as follows image 3 , Figure 4 shown.

[0046] Such as image 3 As shown, the national standard GB18598-2001 "Hazardous Waste Landfill Control Standard" control limit value stipulates that the nickel leaching concentration control limit is 15mg / L, and the nickel leaching concentration of the nickel-containing waste catalyst before treatment is close to 20mg / L, and the cement solidific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com