Double-circular-mold biomass particle forming machine

A biomass pellet and pellet molding machine technology, applied in the direction of die extrusion and pelletization, can solve the problems of waste of resources, low production efficiency, environmental pollution, etc., and achieve total cost reduction, machine wear reduction, and production efficiency improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

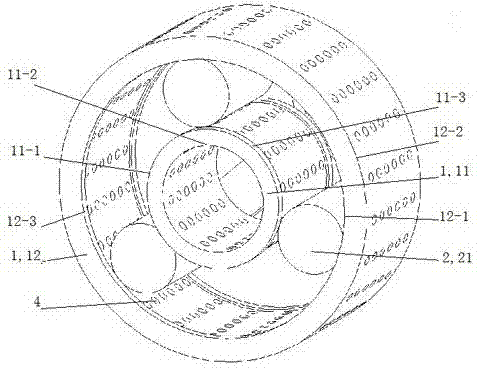

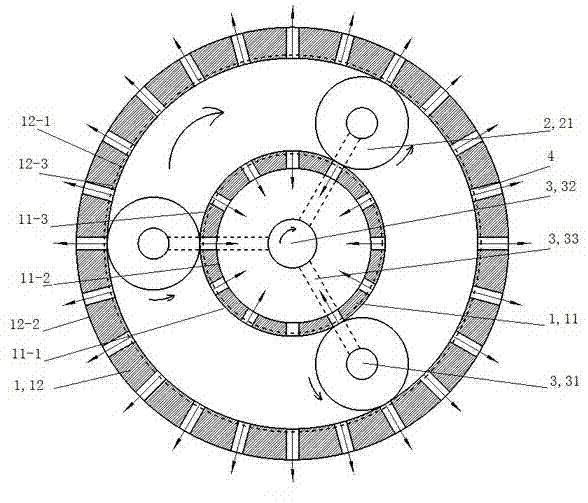

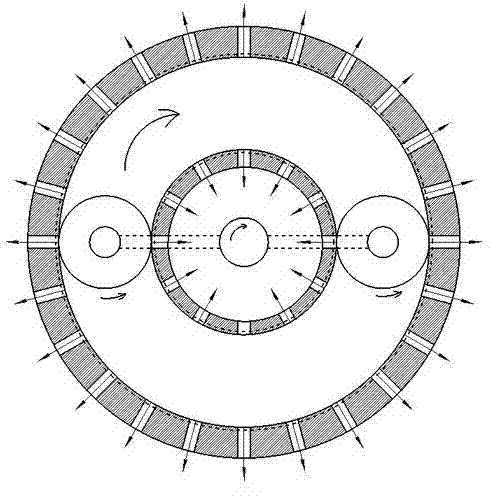

[0031] The present invention includes a power system and a feeding device not shown in the accompanying drawings, and figure 1 The pellet molding machine body shown in , the pellet molding machine body includes a ring die set 1, a press roller set 2 and a press roll drive mechanism 3 connected to the power system; the ring die set 1 consists of an inner ring die 11 and an outer ring die 12 components, the inner ring die 11 and the outer ring die 12 are equipped with granulation holes 4; the pressing roller group 2 is arranged between the inner and outer ring dies and cooperates with the inner and outer ring dies; the pressing rollers drive The mechanism is located between the pressing roller group 2 and the inner ring die 11 .

[0032] According to different types of granulators, the pressure roller group 2 of the present invention can be composed of 1 to 4 pressure rollers 21. Generally, the number of pressure rollers is selected on the basis of considering the space between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com