Cylindrical underground explosion shock wave compaction device

An underwater explosion and compaction device technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of difficult adjustment of explosive parameters, increased cost, uneven billet density, etc., to achieve compact structure, uniform pressure, and compaction good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

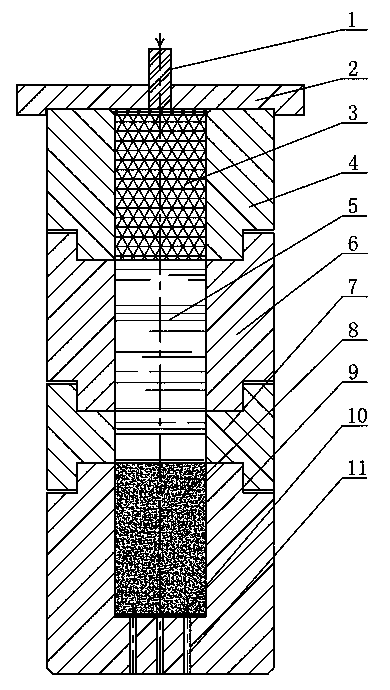

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, the cylindrical underwater explosion shock wave compaction device of this embodiment includes a water pipe 6, the upper end of the water pipe 6 is provided with a groove, the lower end is provided with a boss, and the middle part of the water pipe 6 is provided with a first hole for injecting water 5. There is a through hole, the charging tube 4 is clamped in the groove, the second through hole is opened in the middle of the charging tube 4, and the explosive 3 is placed in it, the top of the charging tube 4 is clamped with a cover plate 2, the cover plate 2 A small hole is opened in the middle, and an electric detonator 1 is installed in the small hole; a water-filled PVC pipe 7 is clamped at the boss of the water-filled pipe 6, and a third through hole for injecting water 5 is opened in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com