A water transfer printing coating film and its production method, surface coating method

A technology of coating film and water transfer printing, which is applied in the direction of copying/marking method, process for producing decorative surface effects, printing, etc., can solve the problems of tediousness and poor spraying effect, improve production efficiency, and ensure drape Covering effect, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

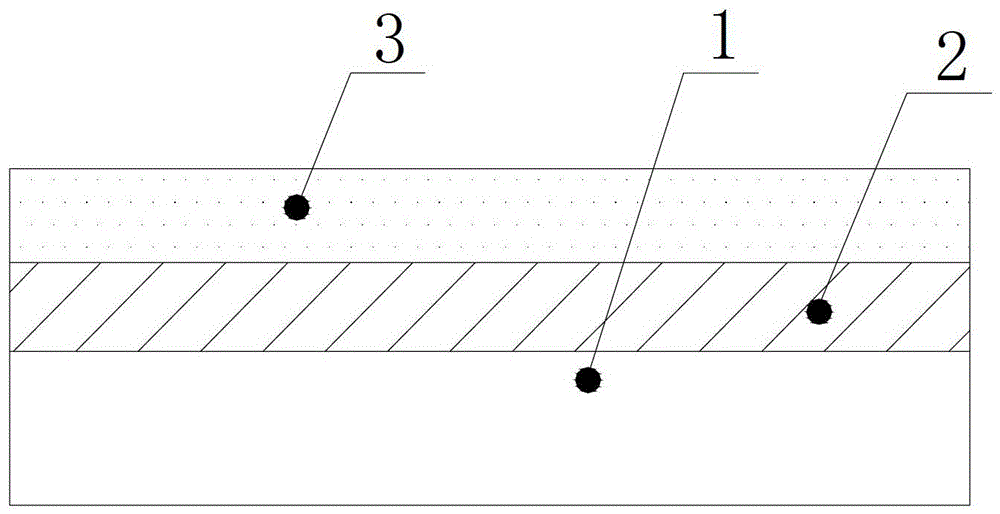

[0036] Such as figure 1 As shown, the water transfer coating film of the present embodiment includes a PVA film 1, a layer of UV photocurable coating 2 formed on the surface of the PVA film 1 and a pattern layer 3 printed on the top of the UV photocurable coating 2 .

[0037] The manufacturing method of the water transfer printing coating film is:

[0038] (1) PVA film is purchased from the market;

[0039] (2) Coating a UV light-curing coating on the PVA film and forming it by UV light irradiation;

[0040] (3) Then print another layer of pattern layer 3 on top of the UV photocuring coating.

[0041] The above-mentioned PVA film can also be replaced by water-based PVC film or water-based PET, and the UV photocurable coating can also be replaced by PU coating or PE coating.

Embodiment 2

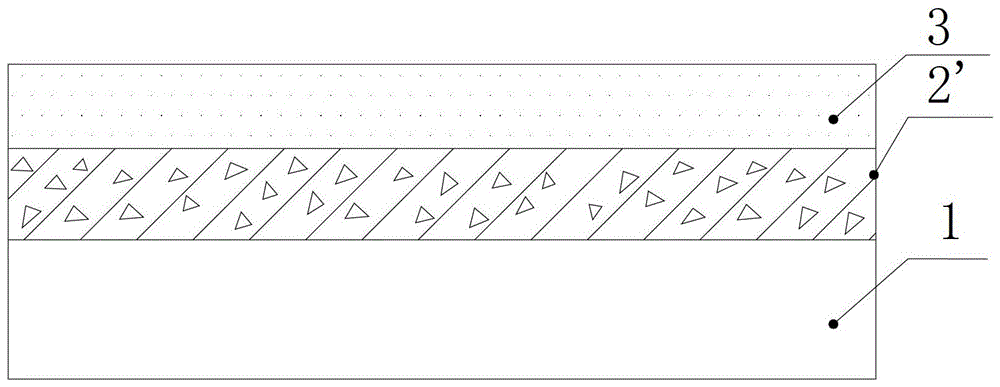

[0043] Such as figure 2 As shown, the water transfer coating film of the present embodiment comprises a PVA film 1, a layer of PU coating 2' containing nano ceramics formed on the surface of the PVA film 1, and a PU coating 2 printed on the surface of the PVA film 1 containing nano ceramics. ' Pattern layer 3 above.

[0044] The manufacturing method of the water transfer printing coating film is:

[0045] (1) A layer of PVA resin is coated on the release paper, and it becomes a transparent PVA film after the PVA resin is dried;

[0046] (2) Add a small amount of 20-80nm nano-ceramics into the PU coating and mix evenly to form a PU coating containing nano-ceramics;

[0047](3) Coating the PU coating containing nano-ceramics obtained in the above steps on the PVA film to obtain a PU coating 2' containing nano-ceramics;

[0048] (4) Then, a pattern layer 3 is printed on the PU coating 2' containing nano-ceramics.

[0049] The above-mentioned PVA films can also be replaced by...

Embodiment 3

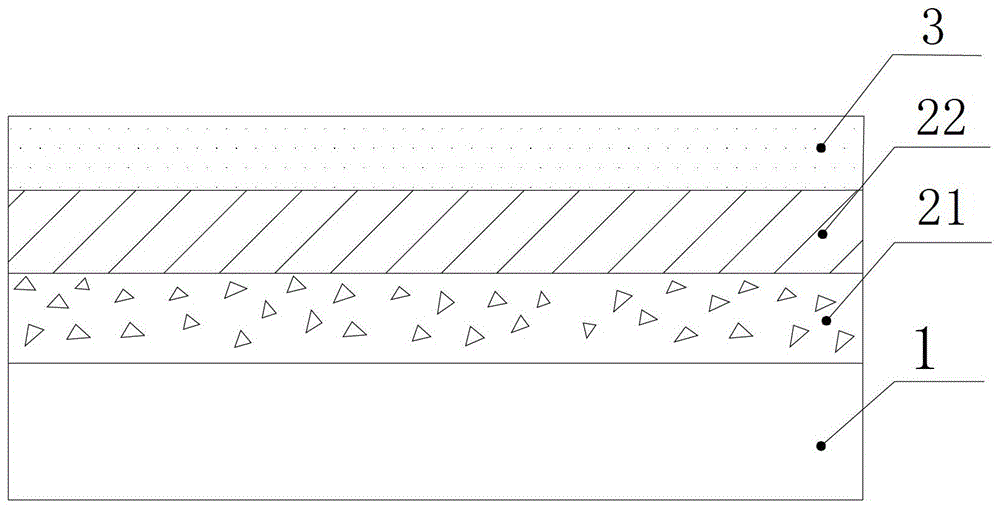

[0051] Such as image 3 As shown, the water transfer coating film of the present embodiment comprises a PVA film 1, a nano-silver oxide coating 21 and a PE coating 22 arranged in sequence from bottom to top formed on the surface of the PVA film 1, and a printed on The pattern layer 3 above the PE coating 22.

[0052] The manufacturing method of the water transfer printing coating film is:

[0053] (1) PVA film is purchased from the market;

[0054] (2) Coating a nano-silver oxide coating 21 on the PVA film;

[0055] (3) Coating a layer of PE coating 22 on the nano-silver oxide coating 21;

[0056] (4) Then, another pattern layer 3 is printed on the PE coating layer 22 .

[0057] The above-mentioned PVA film can also be replaced by water-based PVC film or water-based PET, PE coating can also be replaced by UV coating or PU coating, nano-silver oxide coating can also be replaced by nano-ceramic coating, nano-carbon tube coating or nano-aluminum coating replace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com