High-gloss polyester powder coating containing phosphite and preparation method of high-gloss polyester powder coating

A phosphite, polyester powder technology, applied in polyester coatings, powder coatings, coatings, etc., can solve problems such as poor gloss, achieve high gloss, reduce pollution, and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

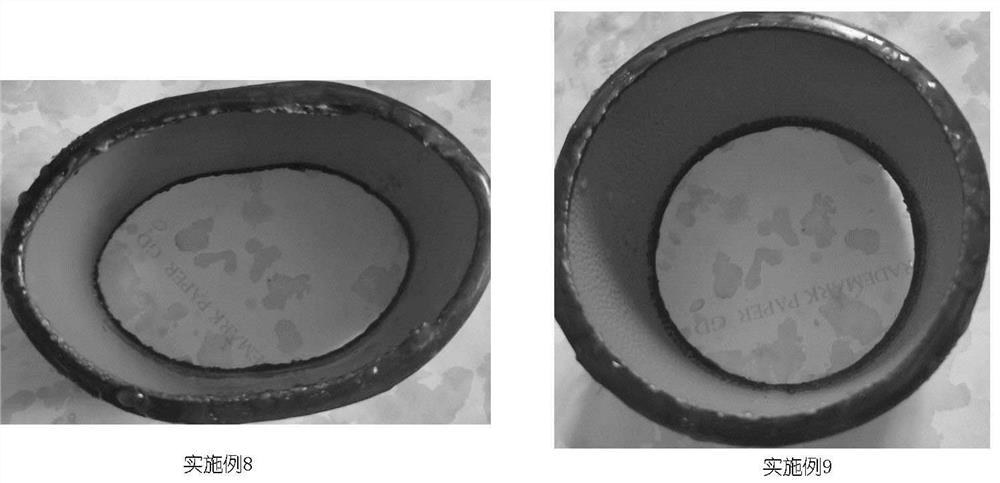

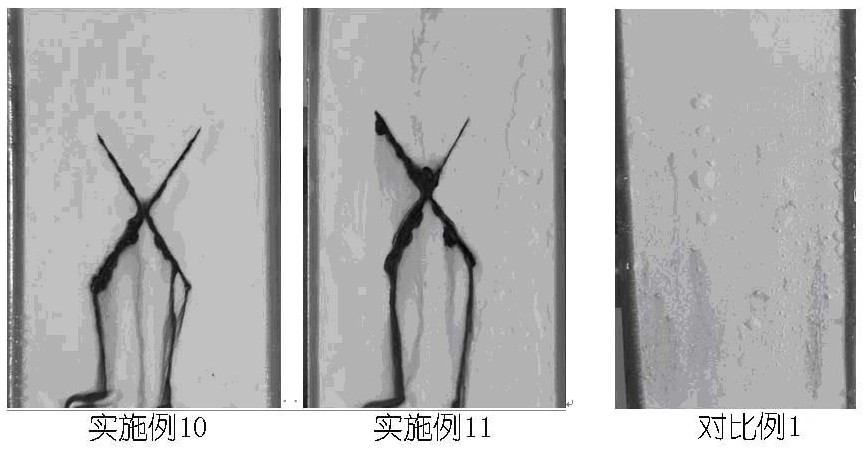

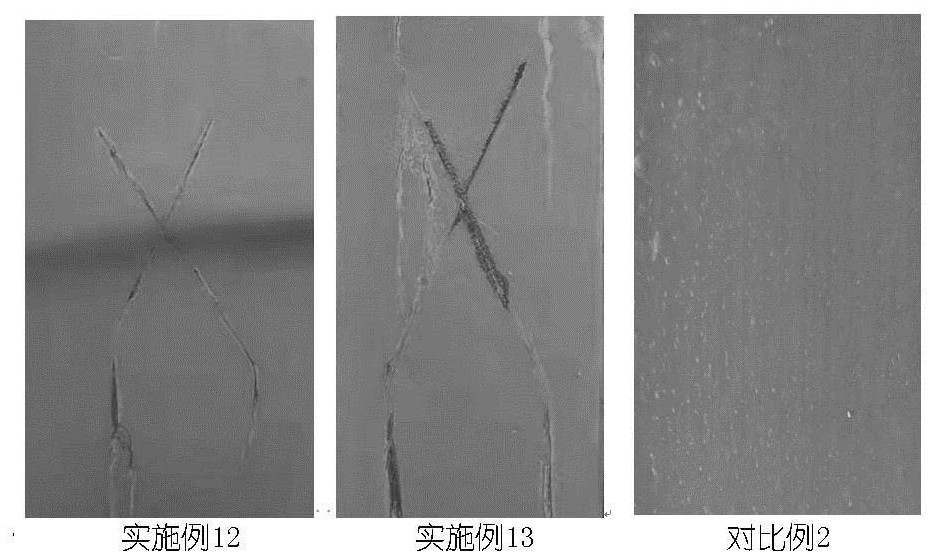

Image

Examples

Embodiment 1

[0025] Phosphite high-gloss polyester powder coating, composition: carboxyl polyester resin (acid value 25mgKOH / g, glass transition temperature 55 ℃) 90 parts, TGIC curing agent 5 parts, strontium phosphite 0.2 parts, titanium dioxide 5.3 parts, quartz Powder 4, 0.05 parts of polyacrylate.

Embodiment 2

[0027] Phosphite high-gloss polyester powder coating, composition: carboxyl polyester resin (acid value 28mgKOH / g, glass transition temperature 60 ℃) 90 parts, TGIC curing agent 20 parts, iron phosphite 19 parts, lithopone 50 parts, 8 parts of modified polysiloxane.

Embodiment 3

[0029] Phosphite high-gloss polyester powder coating, composition: carboxyl polyester resin (acid value 28mgKOH / g, glass transition temperature 60°C) 62.5 parts, TGIC curing agent 30 parts, iron phosphite 2.3 parts, lithopone 0.1 part, 0.2 part of modified polysiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com