Modular catalytic hydrogenation deoxygenation apparatus for nuclear power station

A catalytic hydrogenation and modular technology, applied in the direction of reduced water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of hydrogen discharge safety, increased operating costs, and difficulty in ensuring quality and project progress. Safe and convenient maintenance and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

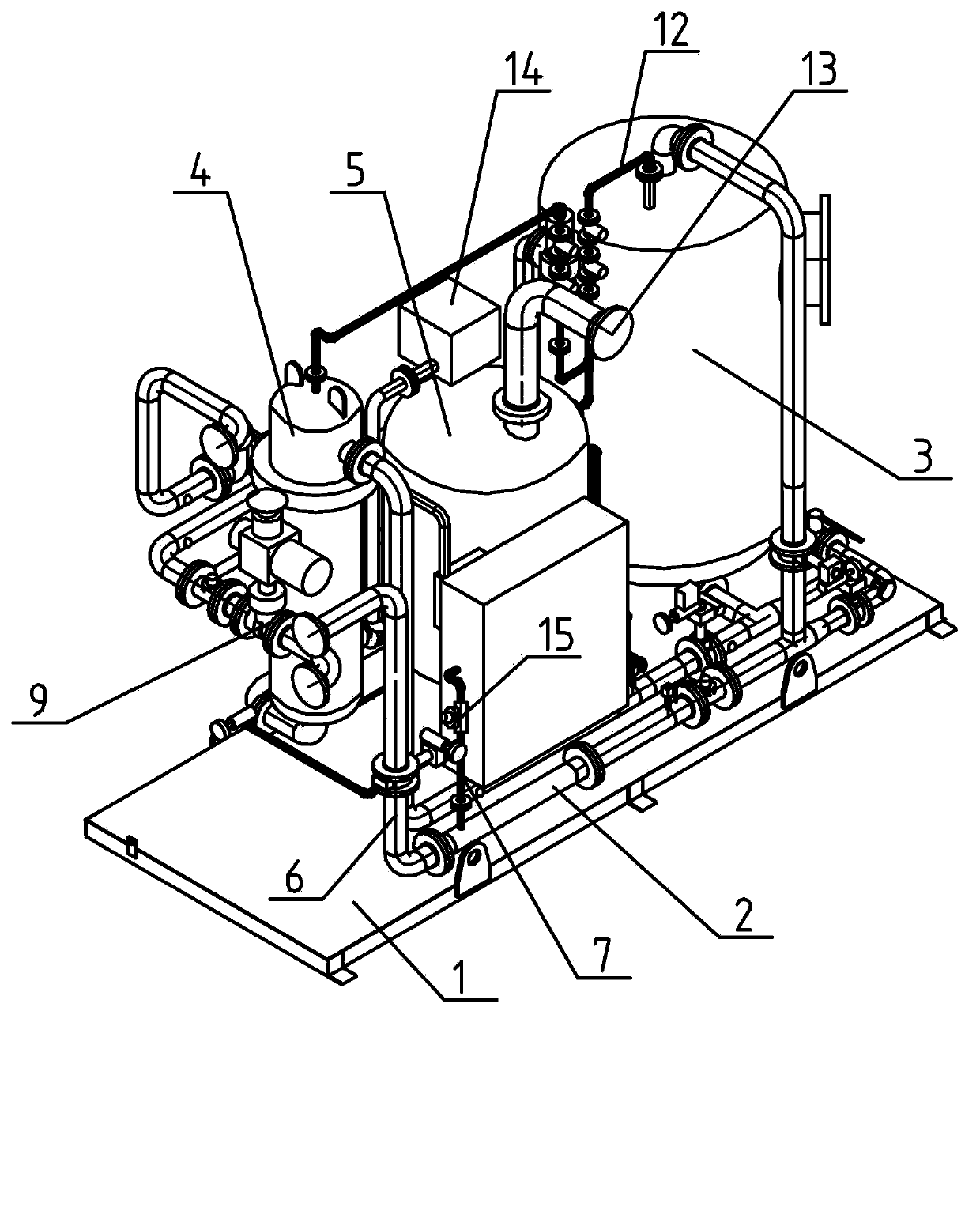

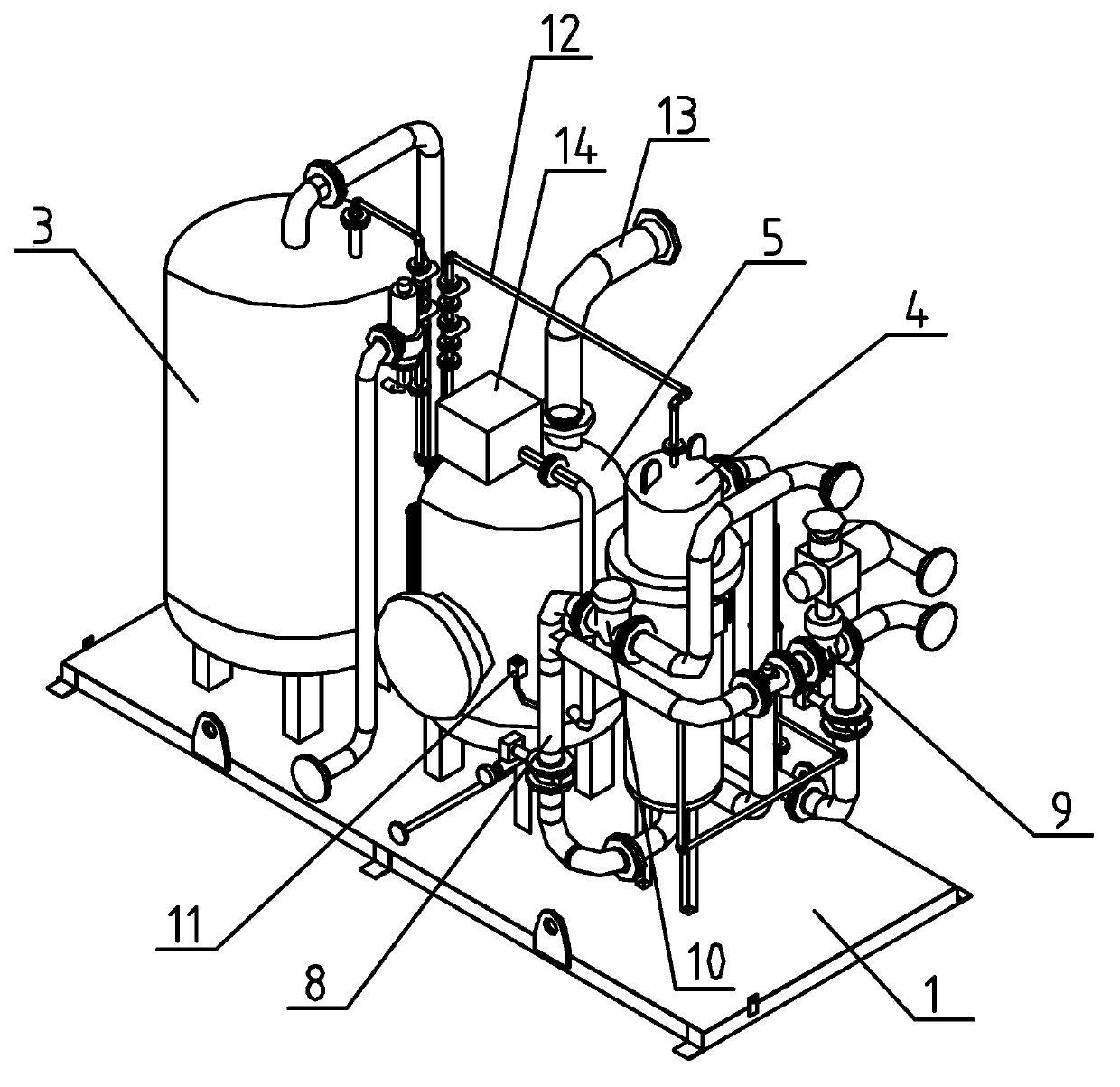

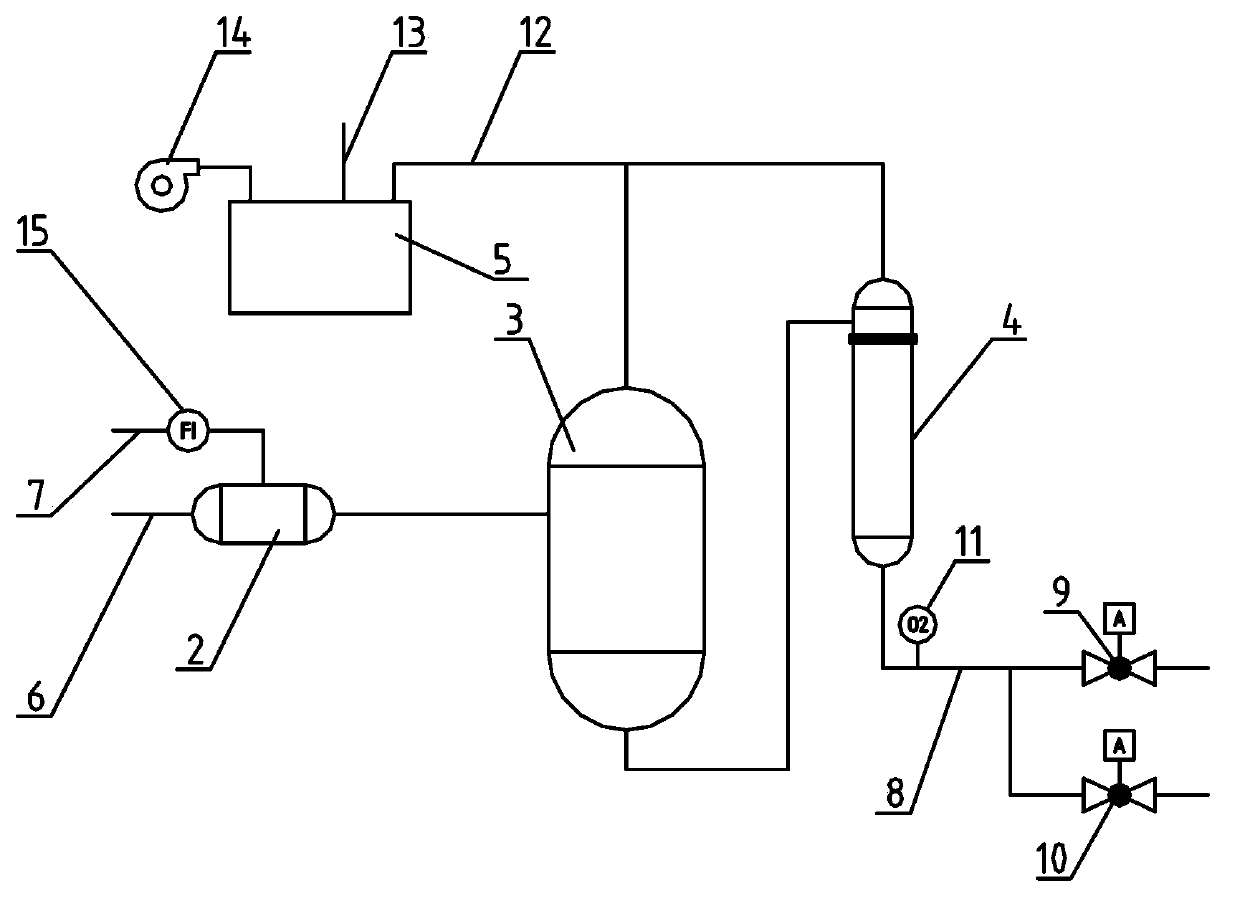

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, but this embodiment should not be construed as limiting the present invention:

[0013] The modular catalytic hydrogenation deoxygenation device for nuclear power plants shown in the figure includes base 1, mixer 2, resin deoxygenation tank 3, resin trap 4 and degassing tank 5, mixer 2, resin deoxygenation tank 3, The resin catcher 4 and the degassing tank 5 are fixed on the base 1 respectively, the mixer 2 is connected with a water inlet pipe 6 and a hydrogenation pipe 7, the water outlet of the mixer 2 is connected with the water inlet of the resin deaeration tank 3, and the resin deoxidizer The water outlet of the oxygen tank 3 is connected with the water inlet of the resin trap 4, and the bottom of the resin trap 4 is connected with the water outlet valve 9 and the circulation valve 10 through the water outlet pipe 8, and the dissolved oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com