A kind of preparation method of biopolymer dust suppressant

A biopolymer and dust suppressant technology, applied in the field of environmental pollution control, can solve the problems of small crust thickness, high viscosity and low density, and achieve the effect of reducing initial cost, convenient dilution operation and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

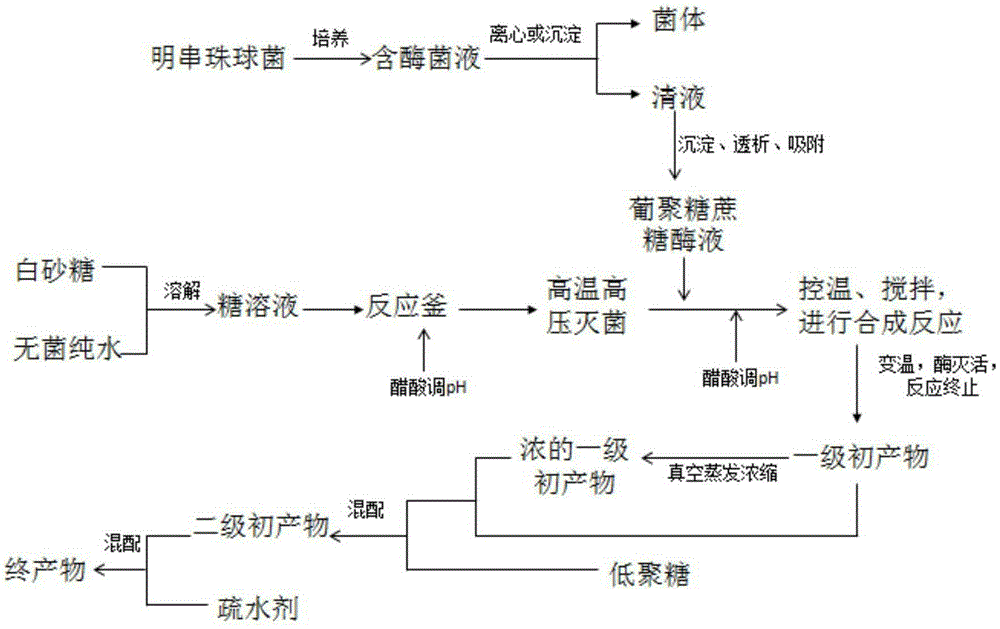

[0038] refer to figure 1 A preferred embodiment of the present invention provides a method for preparing a novel biopolymer dust suppressant, comprising the following steps in order:

[0039] [Step 1] Prepare dextran sucrase enzyme solution:

[0040] a1. Preparation of activation medium: its formula is the following components in mass percentage: 2.0% sucrose, 0.25% yeast powder, 0.5% peptone, 1% dipotassium hydrogen phosphate, 0.05% sodium chloride, 0.02% ferric sulfate, The balance is deionized water; adjust the pH to 7.0-7.4, sterilize at 121°C for 30 minutes, and cool to 25°C±2°C for later use;

[0041] b1. Preparation of enzyme production medium: its formula is the following components in mass percentage: 2.5% sucrose, 1.0% yeast extract, 0.5% peptone, 0.5% dipotassium hydrogen phosphate, 0.05% sodium chloride, and 0.02% ferric sulfate , magnesium sulfate 0.01%, the balance is deionized water; adjust the pH to 6.8-7.2, sterilize at 121°C for 30 minutes, cool for later u...

example 1

[0058] (1) Prepare 100ml of activated medium: weigh 2g of sucrose, 0.25g of yeast powder, 0.5g of peptone, 1g of dipotassium hydrogen phosphate, 0.05g of sodium chloride, and 0.02g of ferric sulfate, dissolve them in distilled water, and adjust the pH value to 7.2. Dilute to 100ml. Use a high-pressure steam sterilizer to sterilize at 121°C for 30 minutes. After the sterilization is completed, take it out and cool it to 25°C for later use.

[0059] Prepare 5000ml of enzyme-producing medium: weigh 125g of sucrose, 50g of yeast extract, 25g of peptone, 25g of dipotassium hydrogen phosphate, 2.5g of sodium chloride, 1.0g of ferric sulfate, and 0.5g of magnesium sulfate, dissolve them in distilled water, and adjust the pH value to 7.0 , set the volume to 5000ml, and use a high-pressure steam sterilizer to sterilize at 121°C for 30 minutes. After the sterilization is completed, take it out and cool it to 25°C for later use;

[0060] (2) In a sterile workbench, inoculate the 100ml o...

example 2

[0073] (1) Preparation of activated medium 1000ml: Weigh 20g of sucrose, 2.5g of yeast powder, 5g of peptone, 10g of dipotassium hydrogen phosphate, 0.5g of sodium chloride, and 0.2g of ferric sulfate, dissolve them in distilled water, adjust the pH value to 7.4, and set Capacity up to 1000ml. Use a high-pressure steam sterilizer to sterilize at 121°C for 30 minutes. After the sterilization is completed, take it out and cool it to 25°C for later use;

[0074] Prepare 100L of enzyme production medium: weigh 2500g of sucrose, 1000g of yeast extract, 500g of peptone, 500g of dipotassium hydrogen phosphate, 50g of sodium chloride, 20g of ferric sulfate, and 10g of magnesium sulfate, dissolve them in distilled water, adjust the pH value to 7.2, and set Capacity to 100L, sterilized at 121°C for 25 minutes, cooled for later use;

[0075] (2) In the aseptic workbench, inoculate the Pleurotus coccus cultured on a solid slope in a refrigerator at 4°C in 1000ml of activation medium, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com