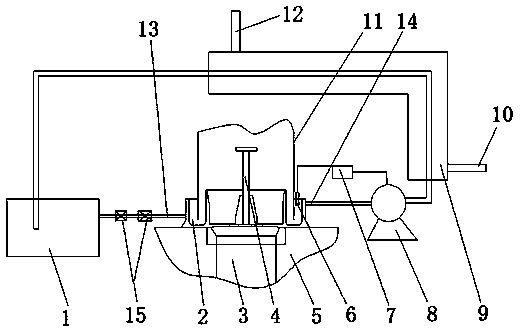

Circular coal loading and smoke guide water sealing system equipment of coke oven

A system equipment and circulation technology, applied in coke oven doors/closers, coke ovens, coke oven heating, etc., can solve the problems of reducing local coke quality, affecting the tightness and life of coke ovens, etc., and achieve coke oven The working environment is safe, the device is simple and practical, and the effect of rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

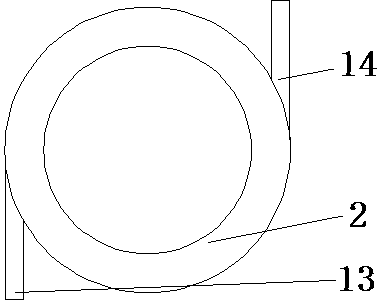

[0013] A circulation type coke oven charging coal smoke guide water seal system equipment, including a water seal seat 2, the water seal seat 2 is arranged on the periphery of the carbonization chamber smoke exhaust hole 3 of the carbonization chamber 5, and the water seal seat 2 is provided with a guide The smoke pipe 11 plays the role of guiding smoke and removing dust. The smoke exhaust hole 3 of the carbonization chamber is provided with a sealing cover 4. The outer surface of the water seal seat 2 is provided with a water inlet pipe B13 and an outlet pipe B14. The outlet pipe B14 is connected to The pumping port of the water pump 8 and the water inlet pipe B13 are connected to the water tank 1 so that the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com