Multi-layer circuit and multi-burner port flameless ceramic burner

A ceramic burner and burner technology, used in blast furnace parts, furnaces, heating furnaces, etc., can solve the problem of uneven airflow distribution in the regenerator, affecting the combustion effect of gas and flame shape, affecting the heat exchange effect of the regenerator, etc. problem, to achieve the effect of large heat load adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

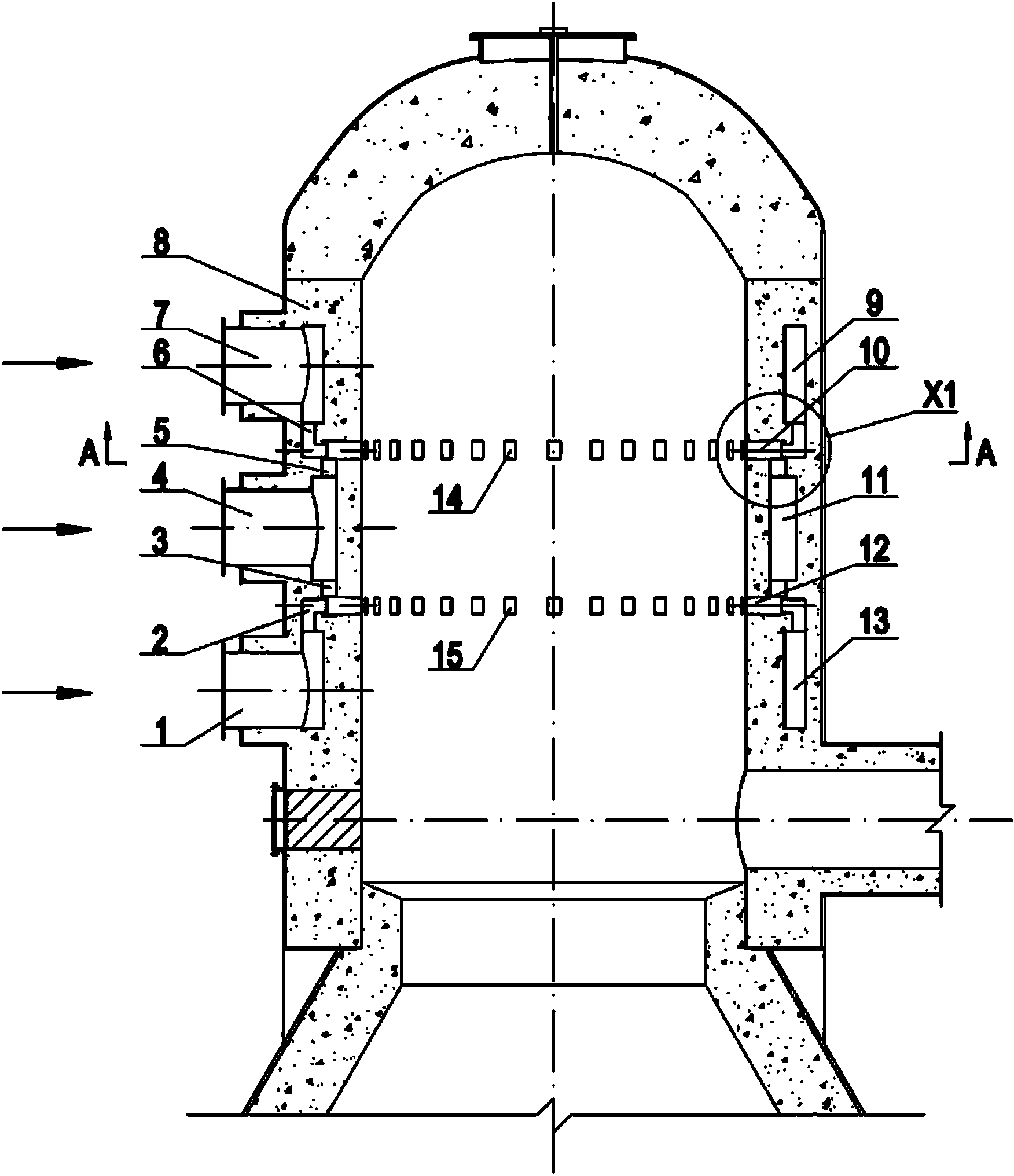

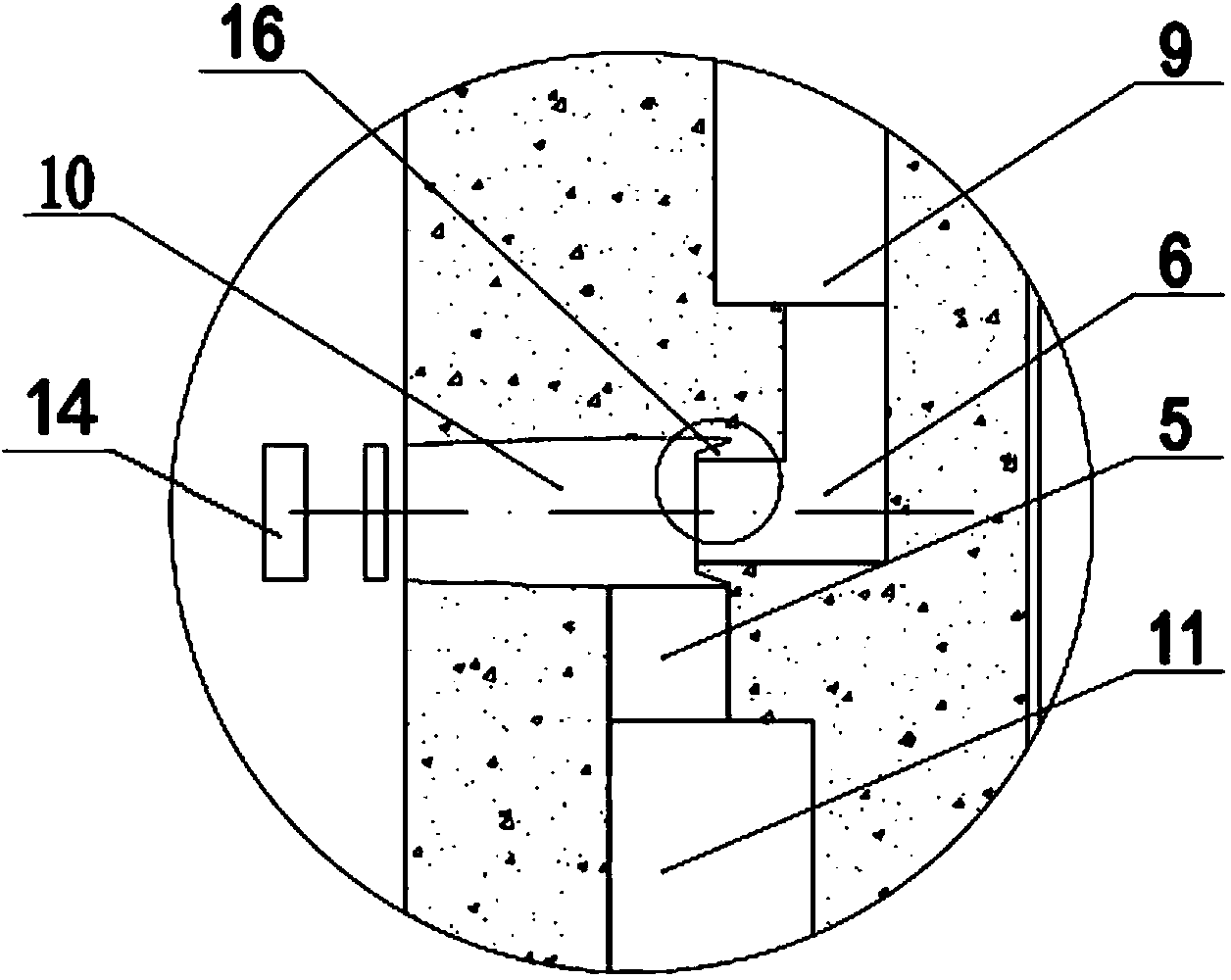

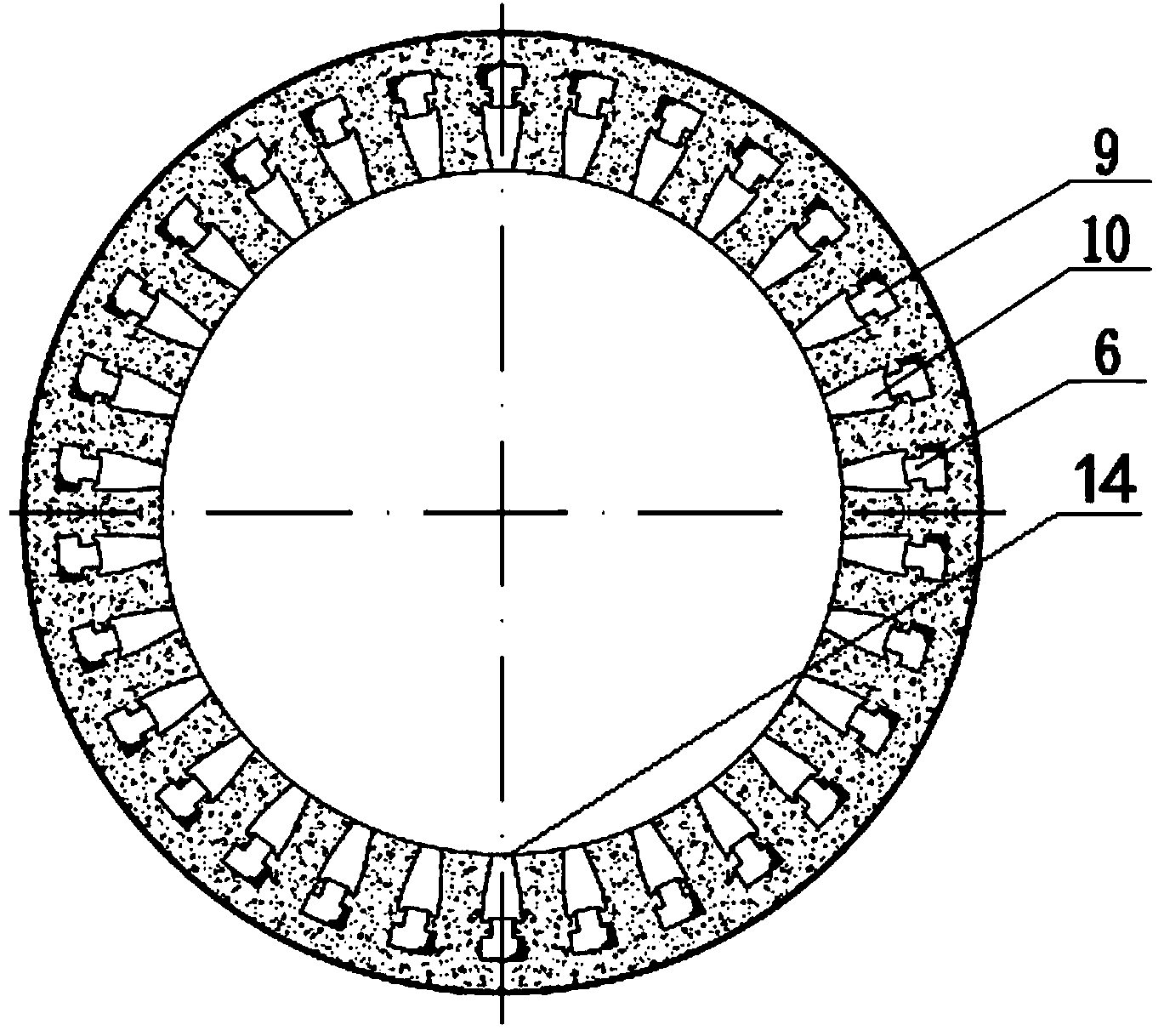

[0032] Embodiment 1: The present invention provides a single set of multi-layer loop multi-flame hole flameless ceramic burner, its structure is as follows figure 1 , 2 , 3, the present invention is on the basis of existing burners with two air inlets, two layers of annular passages, one layer of mixing passages, and one layer of combustion zone structure, in each set of flameless ceramic burners. An air inlet, a layer of annular channel, a layer of mixing channel and a layer of combustion area with many fire holes are added to form a multi-layer annular channel multi-fire hole flameless ceramic burner with three air inlets.

[0033] see figure 1 , the three air inlets are respectively the lower gas inlet 1 and the upper gas inlet 7 arranged in the burner, and the middle air inlet 4 provided between the two gas inlets. This burner is used for top-fired hot air The furnace also burns blast furnace gas. Since the gas flow rate is greater than the air flow rate, the amount of a...

Embodiment 2

[0039] Embodiment 2: The present invention provides a kind of multi-layer loop multi-flame hole flameless ceramic burner used in a single set, see Figure 4 , its structure is basically the same as that of Embodiment 1, the difference is that the positions of the established air inlet and passage are exchanged with the gas inlet and passage, the lower air inlet 17 communicates with the lower air loop, and the upper air inlet 19 communicates with the air passage. The upper ring road is connected, the gas inlet 18 is connected with the gas ring road, and the gas ring road is designed to be different from the air upper ring road and the air lower ring road according to the needs, and the gas upper nozzle hole and the gas lower nozzle in the gas ring road The size is also different to ensure that the gas has different air and gas distribution ratios in the upper fire hole layer and the lower fire hole layer.

Embodiment 3

[0040] Embodiment 3: The present invention provides a combination of three sets of multi-layer ring multi-flame hole flameless ceramic burners, the structure of which is that each set of burners is arranged in sequence from top to bottom, and the air and gas of each set of burners correspond to Independent air inlet, but the size of the fire holes in the multi-layer rings, mixing channels and fire hole layers contained in each set of burners is different.

[0041] The control of the entire combustion system for the combination of 3 sets is: each set of burners adopts an up-and-down arrangement between the rings and fire hole layers inside the burner, and the combustion heat load and combustion-supporting air distribution between the fire hole layers inside the burner are in accordance with Scale setting. For the combustion load distribution ratio, the combustion load decreases in turn from top to bottom, that is, the gas volume burned in the uppermost upper fire hole layer acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com