A method for on-line monitoring and evaluation of cathodic protection

A cathodic protection, on-site technology, applied in the field of corrosion and protection, can solve the problems of short detection time, pipeline interference, unsafe stations, etc., to save manpower, improve accuracy, and ensure effective operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The mining and distribution station at the end of the second line of the Shaanxi-Beijing Pipeline is located in Caiyu Town, Daxing District, Beijing. The natural gas transmission area in the station has an area of about 1200m 2 , There are 21 buried pipelines, the pipe diameters are in the range of Ф33.7mm~Ф1016mm, and a method for on-line monitoring and evaluation of cathodic protection of the present invention is applied.

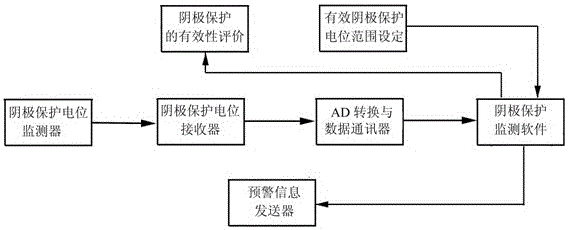

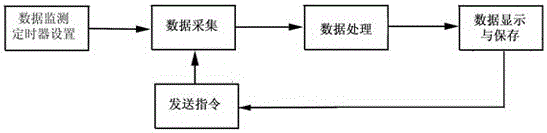

[0031] refer to figure 1 , a cathodic protection site online monitoring and evaluation method, including the following steps:

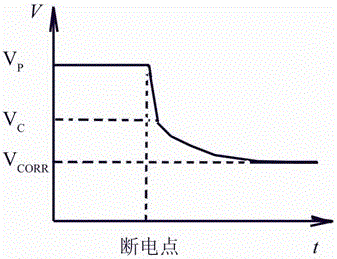

[0032] First, according to the distribution of buried pipelines in the mining and breeding station and the location of the cathode connection point, select 11 monitoring points, excavate a 1.2m deep reference electrode pit at each monitoring point, and place it at a distance of about 0.4m from the pipeline surface 1 long-term saturated copper sulfate electrode, weld a monitoring wire on the pipeline, the reference elect...

Embodiment 2

[0046] The Yongqing Sub-Transportation Station of the Second Line of the Shaanxi-Beijing Pipeline is located in Yongqing County, Langfang City, Hebei Province. The area of the natural gas transmission area in the station is about 19,000m 2 , There are 96 buried pipelines, the pipe diameters are in the range of Ф33.7mm~Ф1016mm, and a method for on-line monitoring and evaluation of cathodic protection of the present invention is applied.

[0047] refer to figure 1 , a cathodic protection site online monitoring and evaluation method, including the following steps:

[0048] First, according to the distribution of buried pipelines in the mining and breeding station and the location of the cathode connection point, select 27 monitoring points, excavate a 1.2m deep reference electrode pit at each monitoring point, and place it about 0.4m away from the surface of the pipeline 1 long-term saturated copper sulfate electrode, and a monitoring wire welded on the pipeline, the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com