A milling rotor

A technology for milling rotors and rotors is applied in the field of road milling machines, which can solve the problems of unfavorable slag collection and large cutting resistance, and achieve the effects of improving the aggregate rate and the exhaust rate, ensuring the milling effect and reducing the difficulty of replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with specific embodiments.

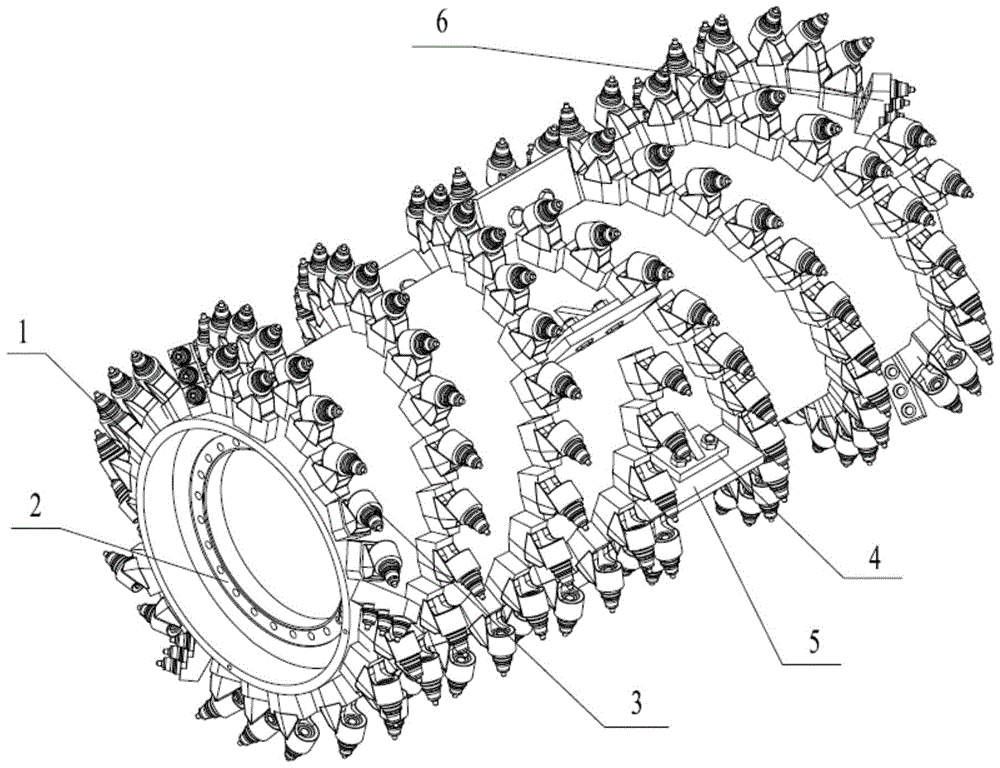

[0016] The structure of a milling rotor provided by the invention is as follows: figure 1 As shown, it includes a cylinder 1, the inner wall of the cylinder 1 is provided with a rotor reducer mounting flange 2, and the outer wall of the cylinder 1 is provided with a plurality of cutter assemblies 3, and the plurality of cutter assemblies 3 are arranged along the cylinder 1. Two groups of helical lines in opposite directions are arranged from the middle to both ends. The middle of the cylinder body 1 is located at the starting point of the helix. There is also a beating plate mounting flange 4. Sheet 5.

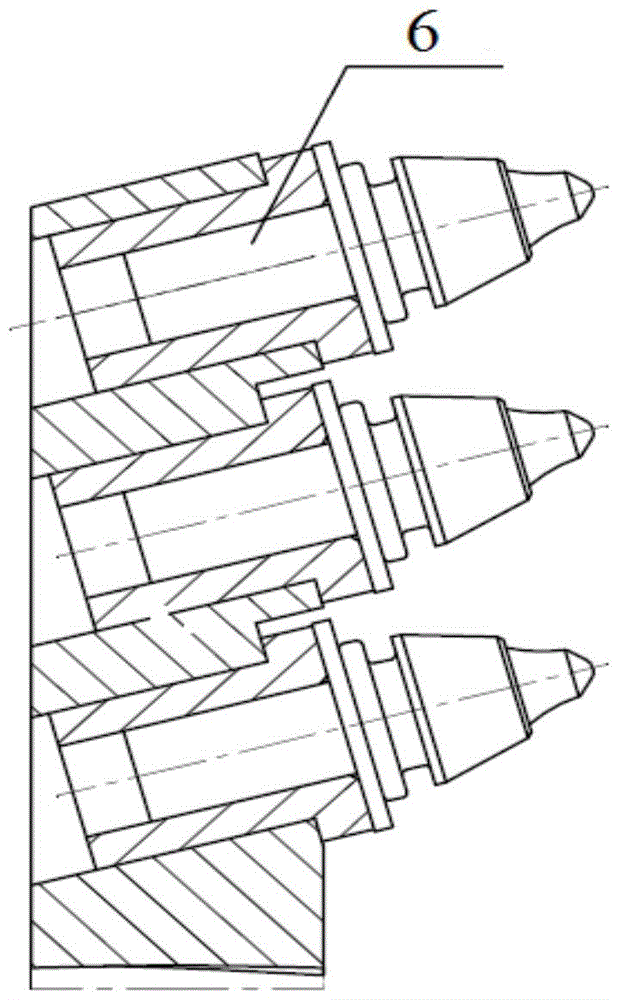

[0017] Such as figure 2 As shown, the cutter assembly 3 at the end of both ends of the barrel 1 is provided with a protective cutter assembly 6 .

[0018] The knockout plate 5 is fixed on the knockout plate flange 4 by bolts.

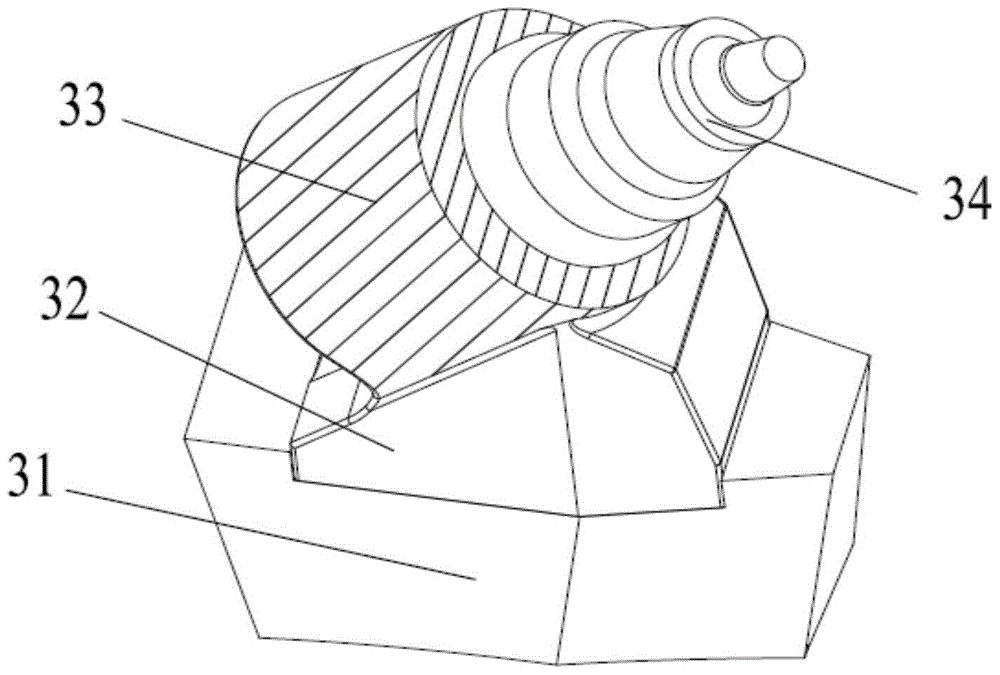

[0019] Such as image 3 and Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com