Portable suspension insulator withstand voltage test system and its withstand voltage test method

A technology of suspension insulator and withstand voltage test, which is applied in the direction of testing the dielectric strength, etc., can solve the problems of increasing the workload of the tester, increasing the safety risk of the site, and the insulation breakdown of the flange to the ground, so as to facilitate site movement and reduce The number of preparations and the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

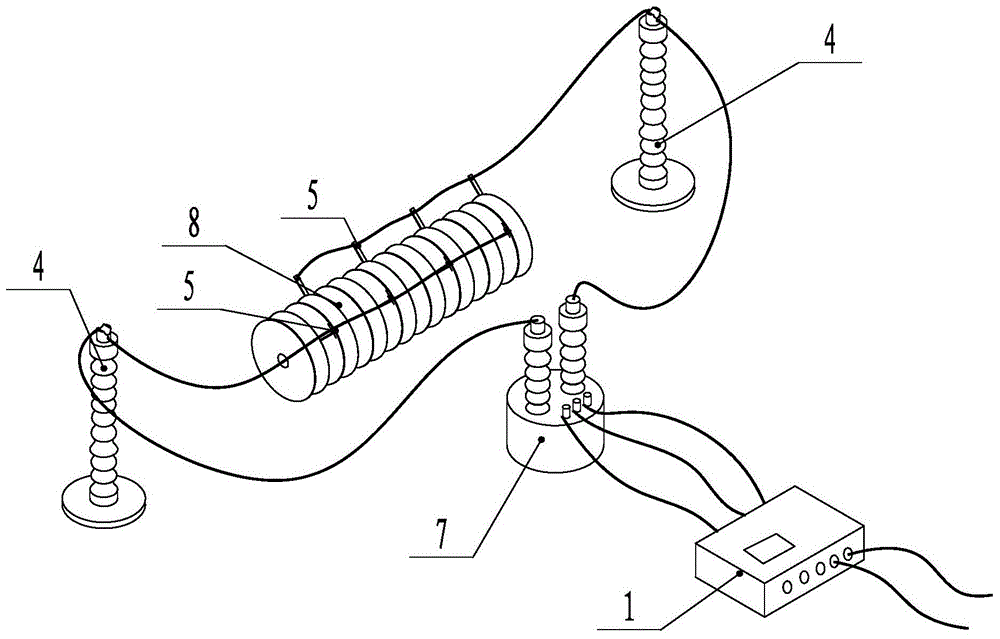

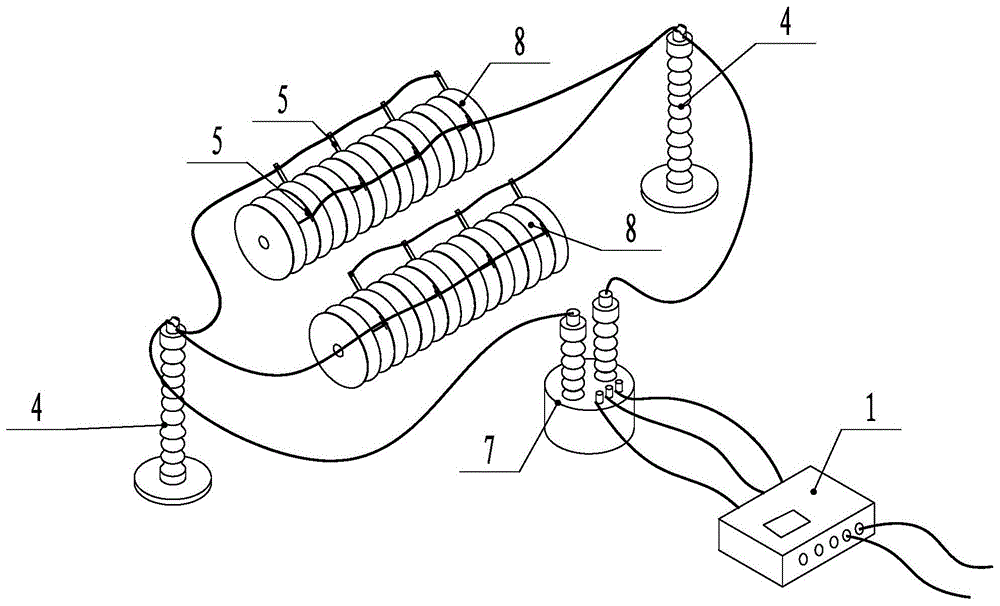

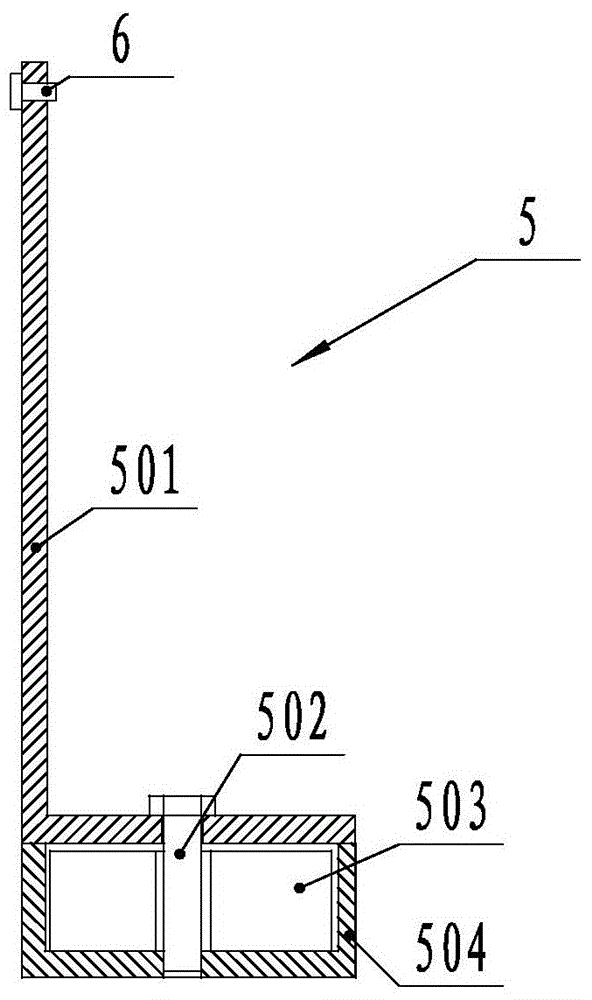

[0037] Such as figure 1 As shown, the present invention includes a voltage regulator 1 connected to a 220V AC power supply, a first excitation transformer 2, a second excitation transformer 3, two insulating pillars 4, and a magnetic connecting rod 5; the first output terminal of the voltage regulator 1 is connected to the The first input end of the first excitation transformer 2 and the second input end of the second excitation transformer 3 are connected, and the second output end of the voltage regulator 1 is connected with the second input end of the first excitation transformer 2 and the second input end of the second excitation transformer 3. The first input end is connected so that the first excitation transformer 2 and the second excitation transformer 3 output voltages with equal amplitudes and opposite phases; the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com