Construction and using method of VRB (Variable Thickness Rolled Blank) forming limit stress diagram

A technology of forming limits and stress diagrams, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the inability to predict the forming ability of thickened plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

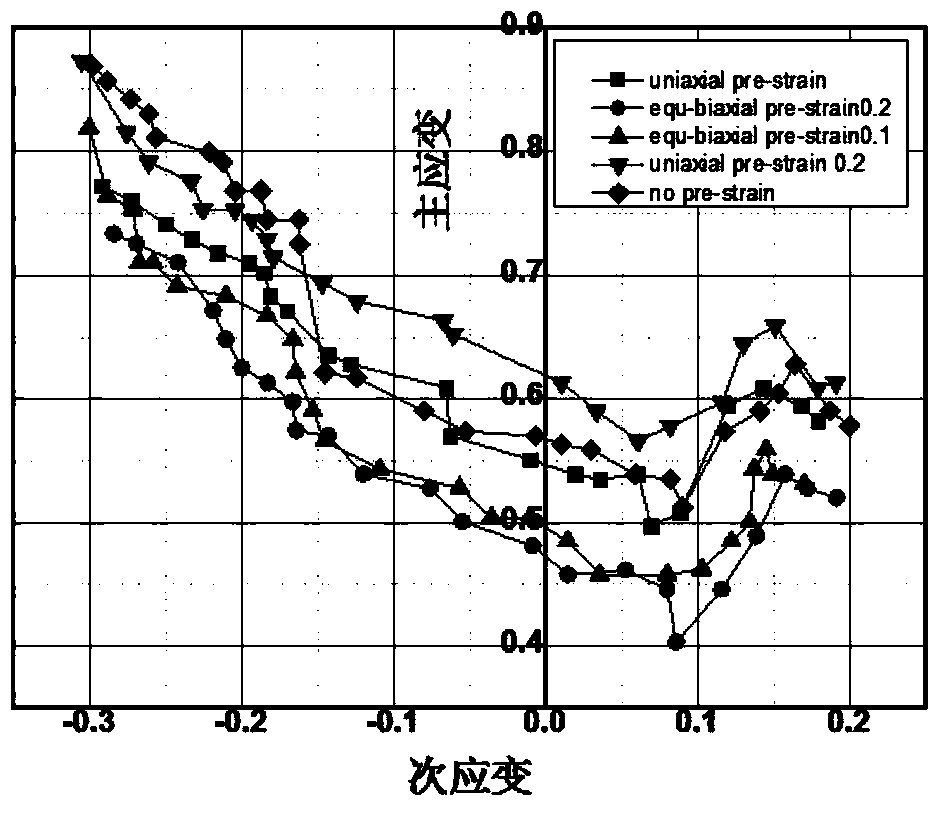

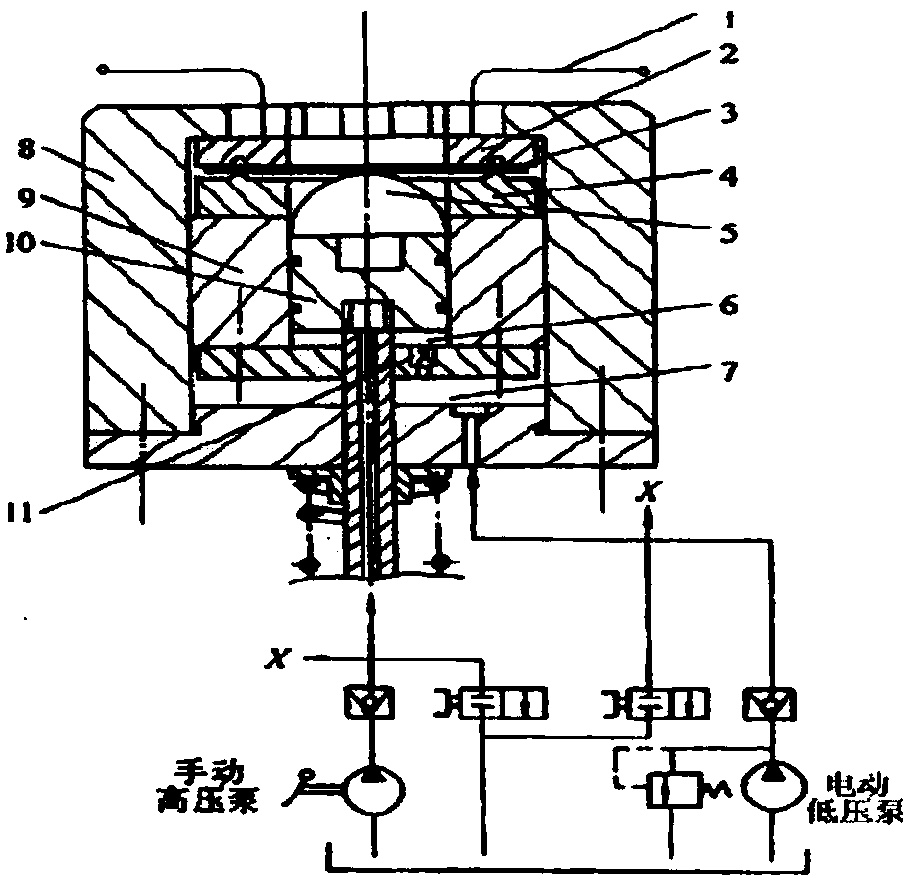

[0036] The following will be combined with the manual Figure 1-12 The present invention is described in detail with embodiment.

[0037] The invention provides a method for constructing the forming limit stress diagram of a thickened plate, which specifically includes the following steps:

[0038] Step 1. Determination of the basic parameters of the sample material, wherein the basic parameters of the material include the material thickness anisotropy index r, the material strain hardening index n, and the material constant K;

[0039] The specific calculation refers to the national standard GB / T5028-1999 for the test method of the strain hardening index (n value) of the metal sheet and strip and the national standard GB / T5027-1999 for the test method of the plastic strain ratio (r value) of the metal sheet and strip.

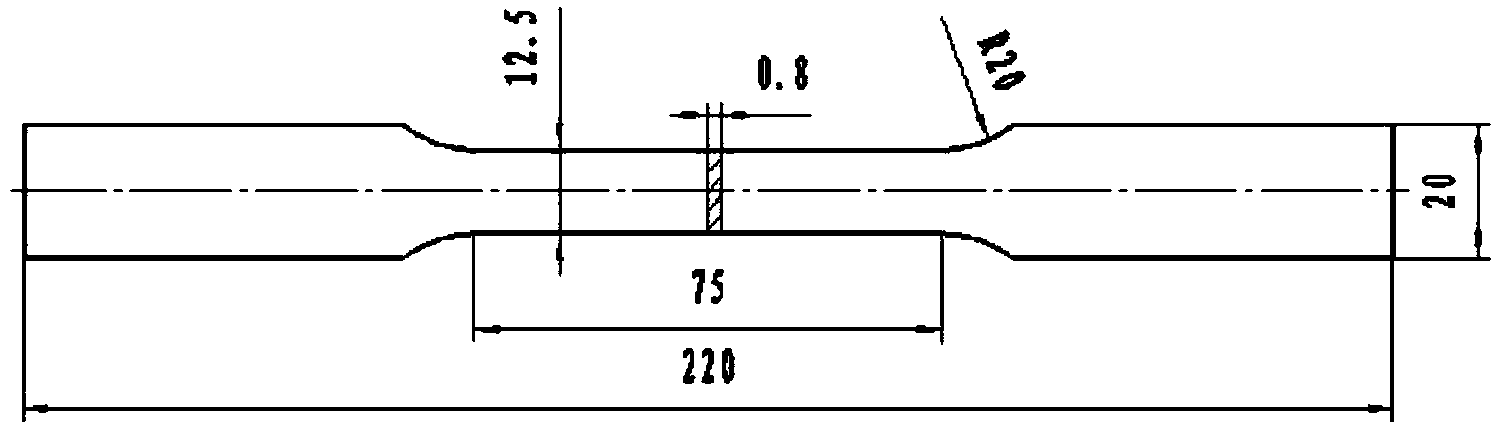

[0040] Such as figure 1 As shown, the sample is made of high-strength boron steel 22MnB5 steel, the thickness is 0.8mm, the gauge length is 75mm and the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com