Mud flat wave current oblique crossing simulation method

A simulation method, wave and current technology, applied in the field of coastal engineering model tests, can solve the problems of high cost, inability to obtain the combined effect of wind wave sand lifting and tidal sand transport, and difficulty in simulating the impact of bed-making sediment, so as to achieve economical production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

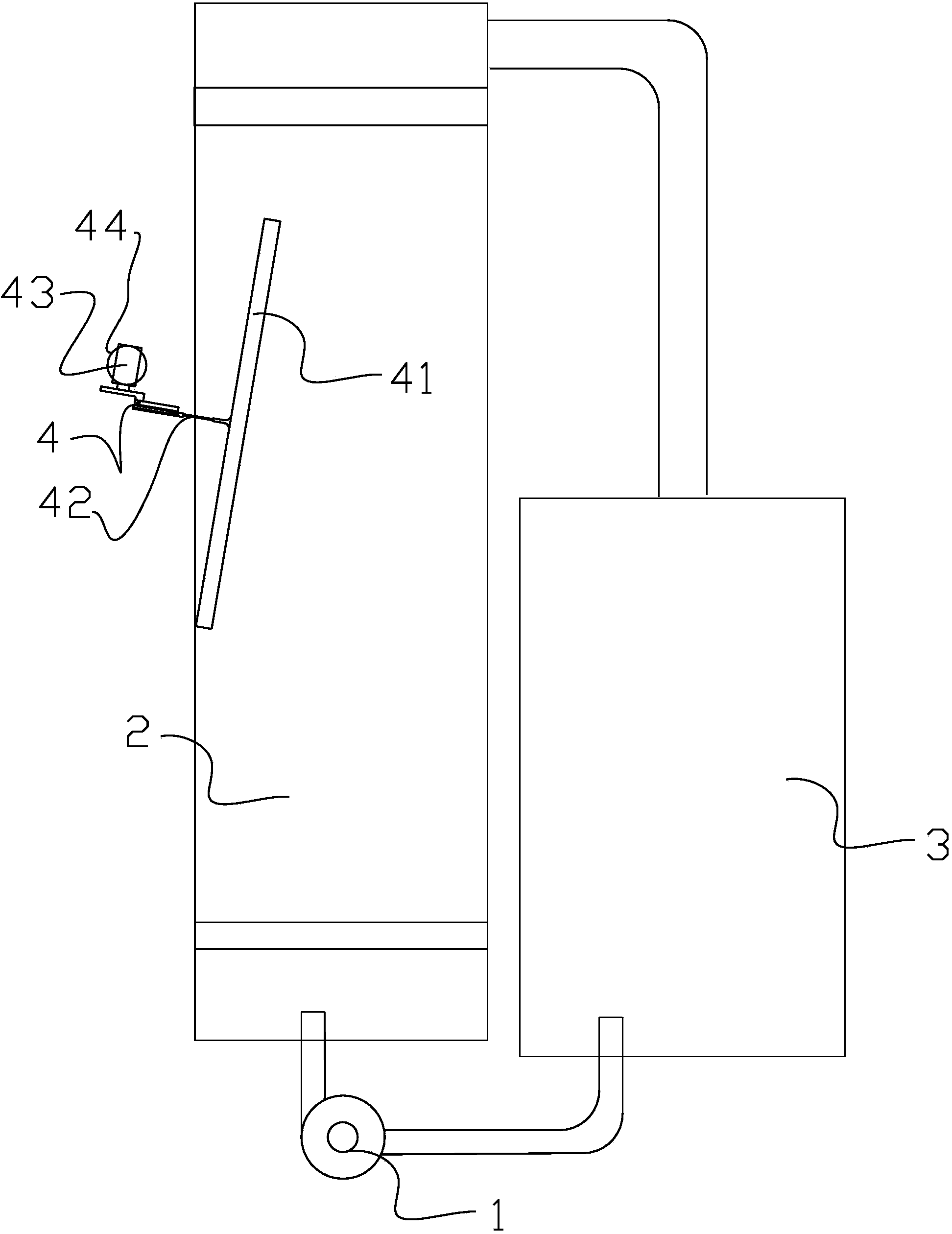

[0043] A muddy tidal flat wave flow oblique simulated water tank device in water conservancy model tests, including a mainstream pump 1, a water tank 2, an underground reservoir 3, and a wave maker 4; the outlet of the mainstream pump 1 is set at the water inlet of the water tank 2 end, the inlet is set in the underground reservoir 3; the water outlet of the tank 2 is connected to the underground reservoir 3, the main flow pump 1 drives the water flow to circulate between the tank 2 and the underground reservoir 3, and the wave maker 4 is arranged on the left side of the tank 2 or Right.

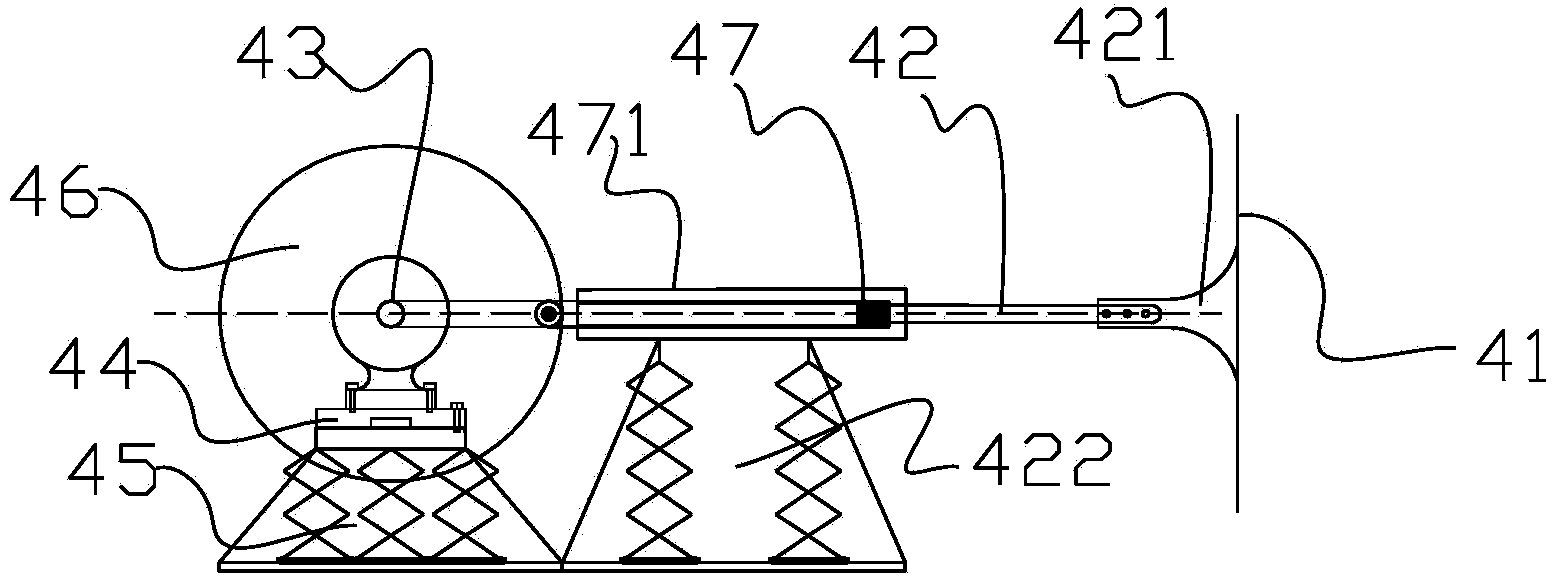

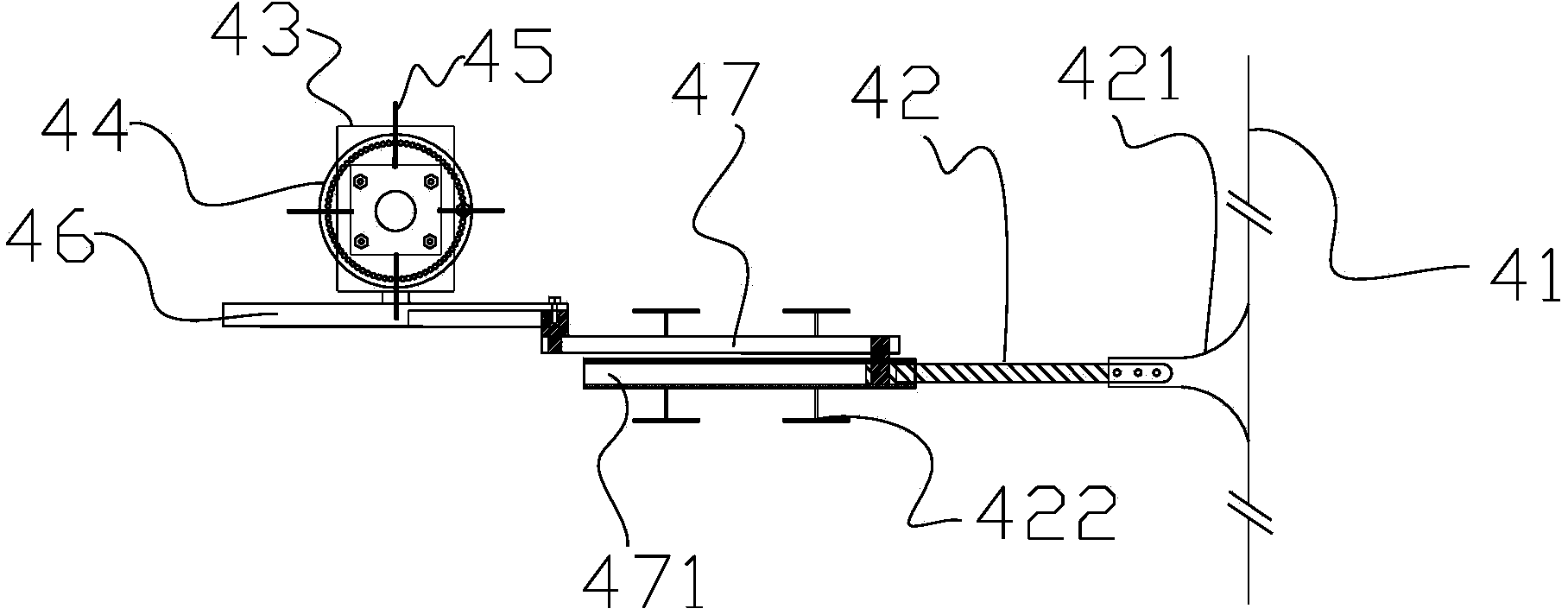

[0044] The wave maker 4 includes: a wave pushing plate 41, a pushing arm 42, a wave pushing motor 43, a rotating platform 44 and an integral lifting bracket 45; the wave pushing plate 41 is connected to the wave pushing motor 43 through a pushing arm 42; T...

Embodiment 2

[0056] A muddy tidal flat wave flow oblique simulated water tank device in water conservancy model tests, including a mainstream pump 1, a water tank 2, an underground reservoir 3, and a wave maker 4; the outlet of the mainstream pump 1 is set at the water inlet of the water tank 2 end, the inlet is set in the underground reservoir 3; the water outlet of the tank 2 is connected to the underground reservoir 3, the main flow pump 1 drives the water flow to circulate between the tank 2 and the underground reservoir 3, and the wave maker 4 is arranged on the left side of the tank 2 or Right.

[0057] The wave maker 4 includes: a wave pushing plate 41, a pushing arm 42, a wave pushing motor 43, a rotating platform 44 and an integral lifting bracket 45; the wave pushing plate 41 is connected to the wave pushing motor 43 through a pushing arm 42; The rotating platform 44 is fixed on the top of the integral lifting support 45 ; the wave pushing motor 43 is fixed on the rotating platfo...

Embodiment 3

[0069] A muddy tidal flat wave flow oblique simulated water tank device in water conservancy model tests, including a mainstream pump 1, a water tank 2, an underground reservoir 3, and a wave maker 4; the outlet of the mainstream pump 1 is set at the water inlet of the water tank 2 end, the inlet is set in the underground reservoir 3; the water outlet of the tank 2 is connected to the underground reservoir 3, the main flow pump 1 drives the water flow to circulate between the tank 2 and the underground reservoir 3, and the wave maker 4 is arranged on the left side of the tank 2 or Right.

[0070] The wave maker 4 includes: a wave pushing plate 41, a pushing arm 42, a wave pushing motor 43, a rotating platform 44 and an integral lifting bracket 45; the wave pushing plate 41 is connected to the wave pushing motor 43 through a pushing arm 42; The rotating platform 44 is fixed on the top of the integral lifting support 45 ; the wave pushing motor 43 is fixed on the rotating platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com