IGBT and manufacturing method thereof

A semiconductor and shallow well technology, applied in the field of semiconductor device manufacturing technology, can solve problems such as latch-up effect, weak anti-latch-up ability, and small current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As mentioned in the background, the existing IGBT has low latch-up current and weak latch-up resistance.

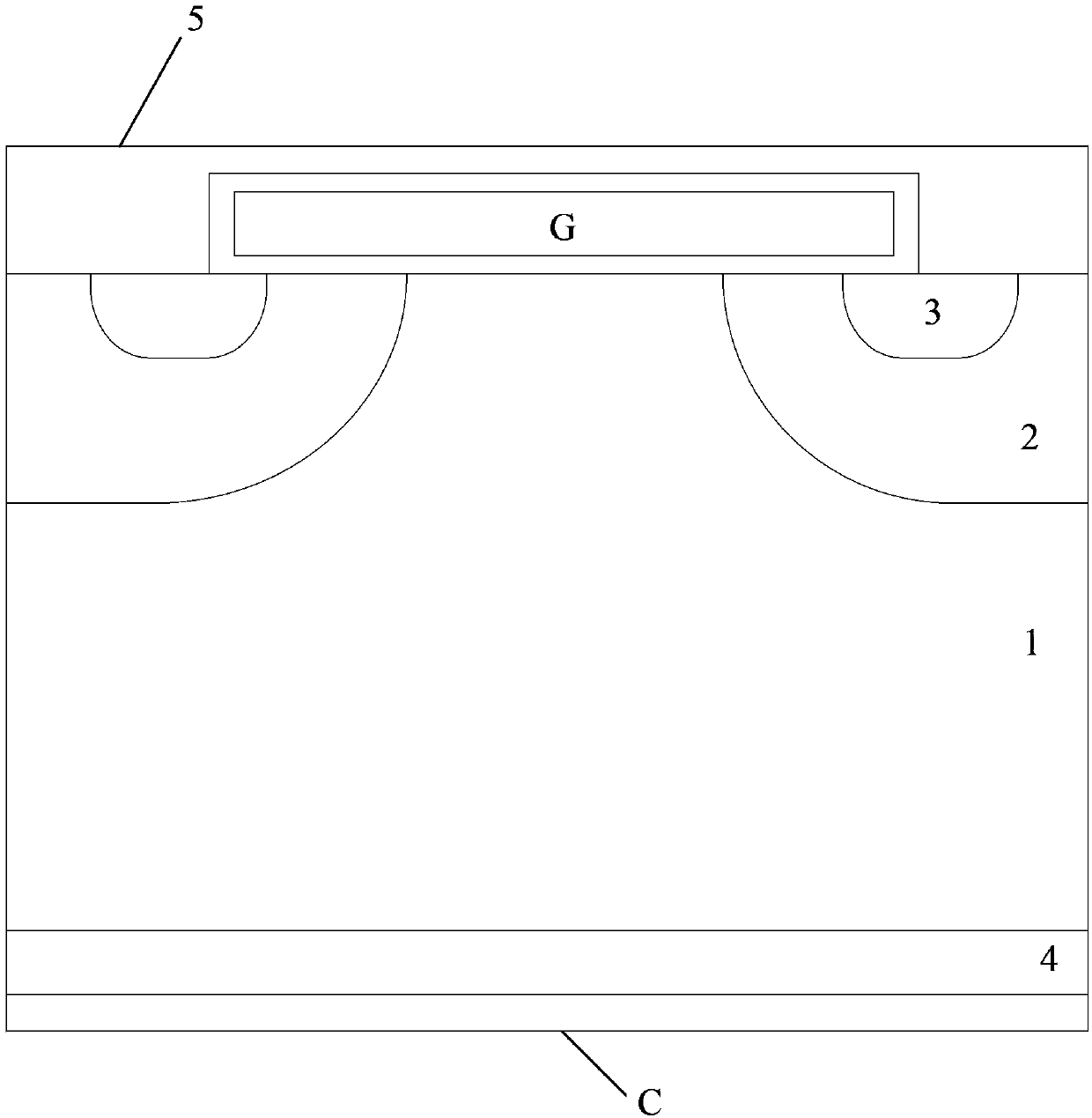

[0039] refer to figure 1 ,exist figure 1 In the shown IGBT, its N + Source region 3, P-type well region 2, N - drift region and P + Collector 4 constitutes a parasitic NPNP thyristor. The NPNP thyristor includes: NPN transistor Q1 (N + Source region 3-P-type well region 2-N-drift region) and PNP transistor Q2 (P-type well region 2-N- - Drift Zone-P + collector area 4). IGBT has three PN junctions: N + PN junction J3 between source region 3 and P-type well region 2, P-type well region 2 and N - PN junction J2 between the drift region, N - Drift region and P + PN junction J1 between collector regions 4 . Wherein, the drift region is a part of the semiconductor substrate that does not include the well region, the source region and the collector region.

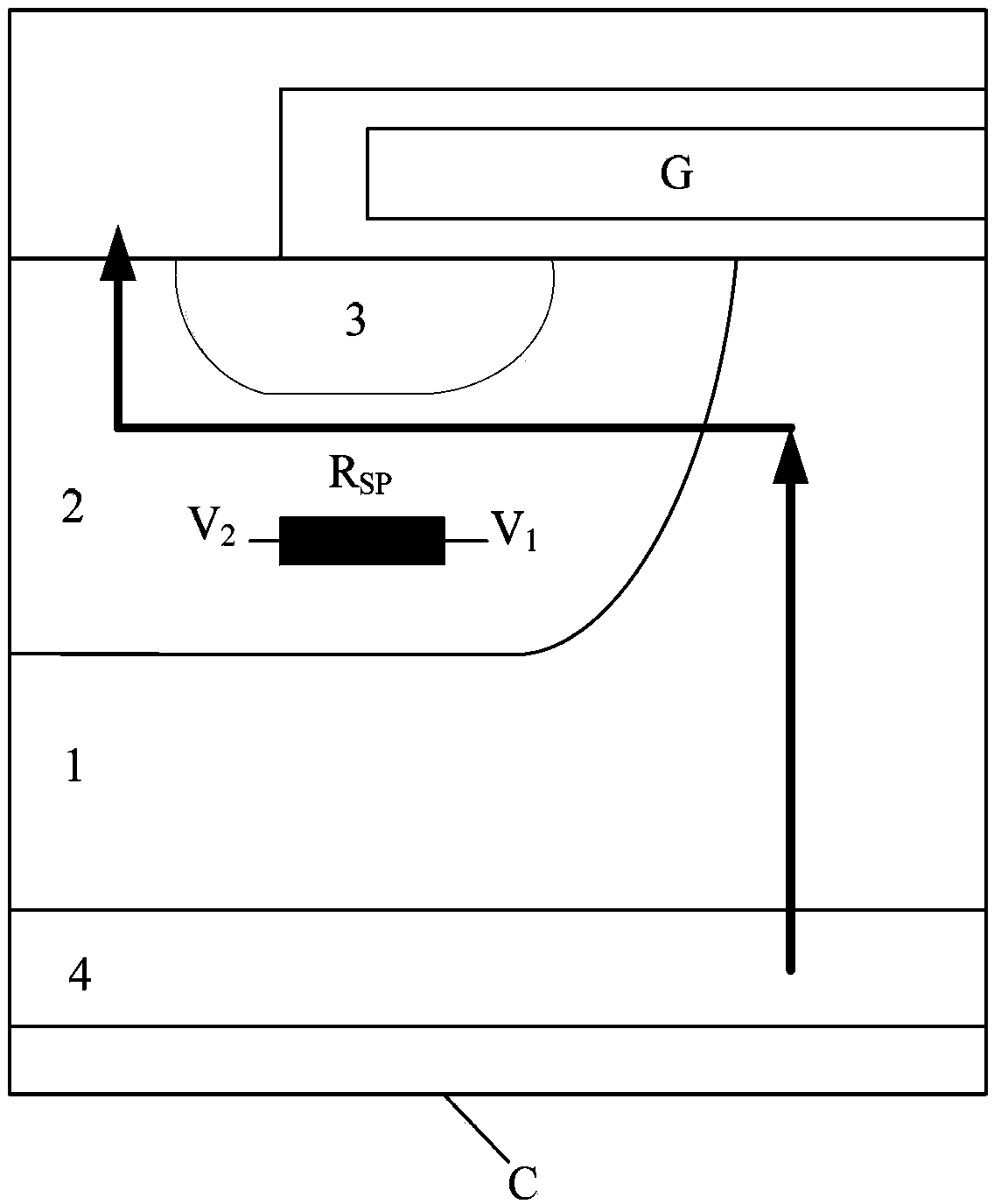

[0040] refer to figure 2 , figure 2 for figure 1 Schematic diagram of the equivalent analysis of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com