Method for manufacturing non-planar polymer lithium battery

A manufacturing method and non-planar technology, applied in the direction of non-aqueous electrolyte storage battery, electrolyte storage battery manufacturing, battery pack components, etc., to achieve the effect of ensuring shape and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

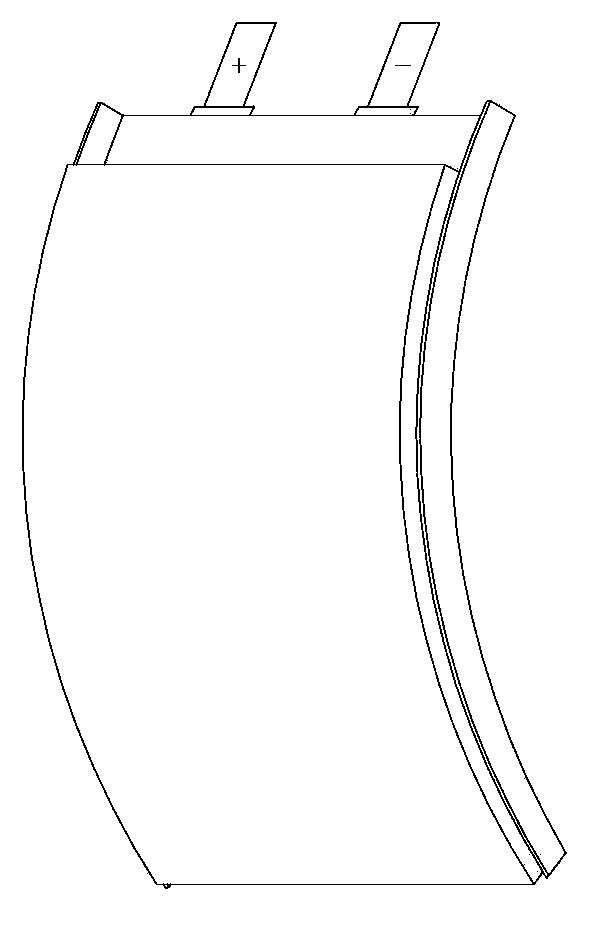

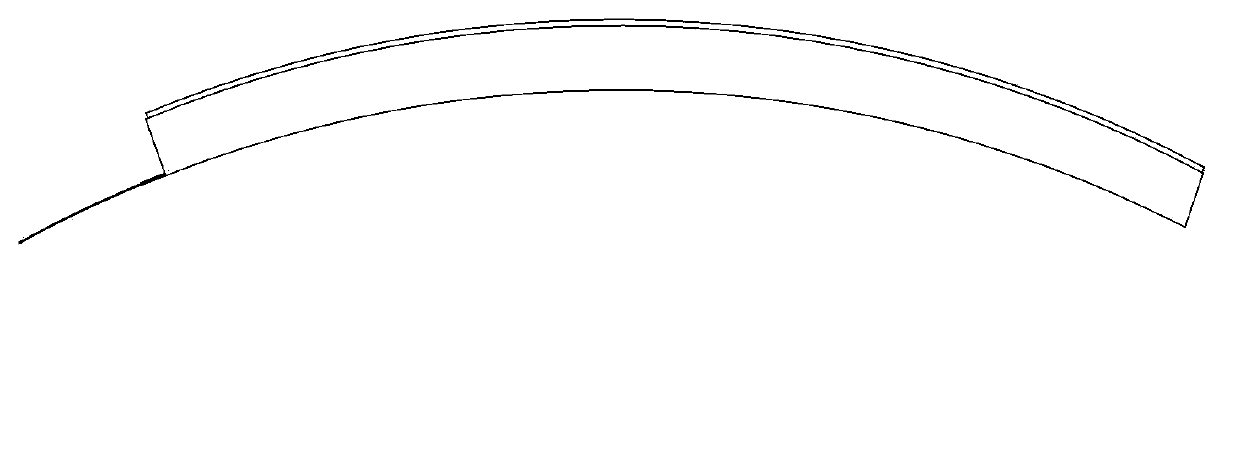

[0027] The non-planar polymer lithium battery technology of the present invention comprises the following steps,

[0028] 1) Coat a layer of polyvinylidene fluoride on the upper and lower surfaces of the plane positive and negative electrodes, and the coating amount of polyvinylidene fluoride is 0.1-0.3mg / cm 2 , preferably 0.2mg / cm 2 , Coating a layer of polyvinylidene fluoride on the surface of the pole piece, polyvinylidene fluoride is characterized by making the pole piece plastic within a certain range, so that the pole piece has the characteristics of maintaining a certain shape. At the same time, because the thickness of the polyvinylidene fluoride layer is very small, about 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com