Ceramic electric heater for water tank

A technology of electric heater and electric heating element, which is applied in the mechanical field, can solve the problems of coating peeling, low heat load, large size of electric heating tube, etc., and achieve the effect of uniform water temperature, good performance and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

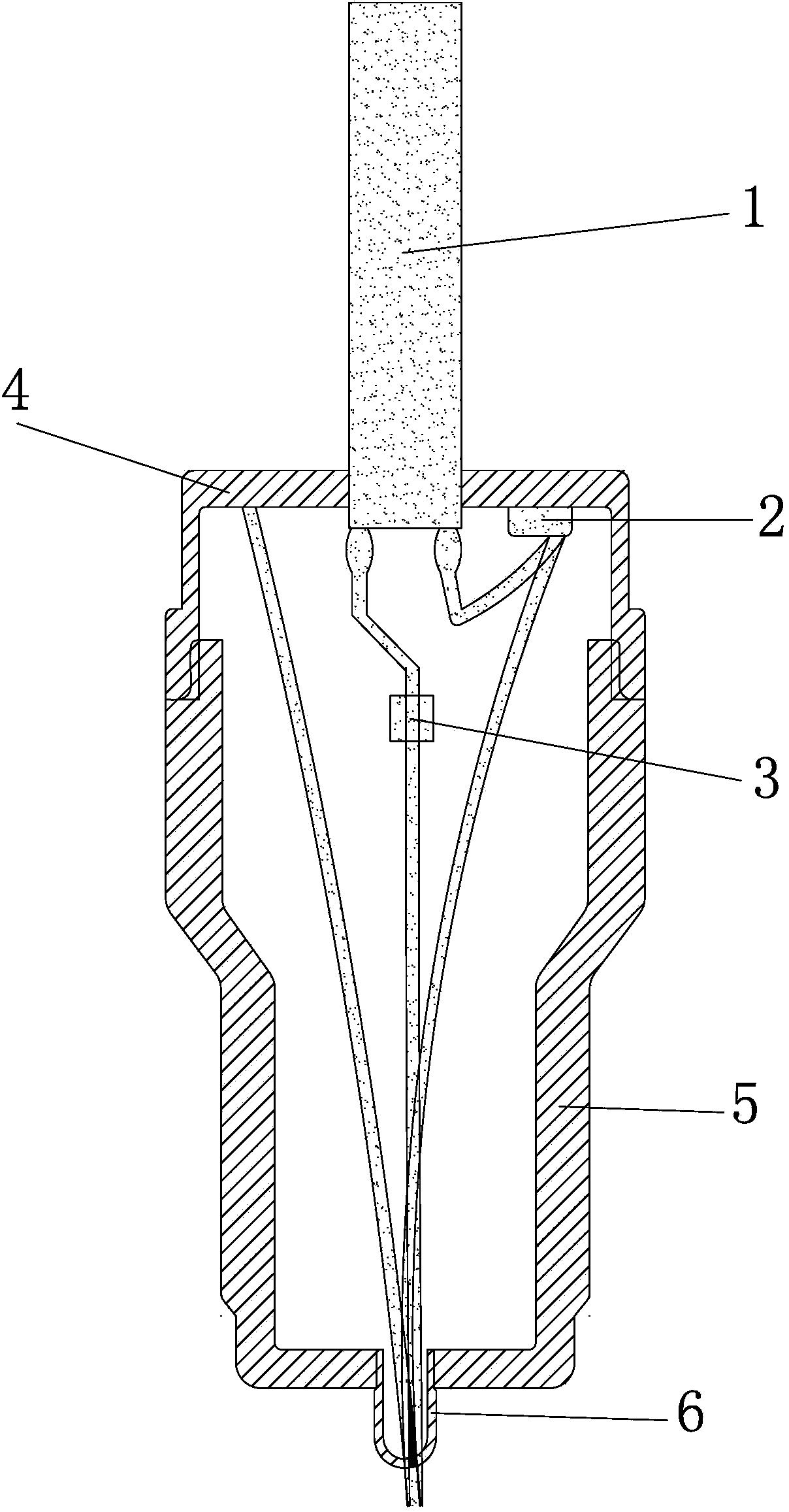

[0021] Such as figure 1 As shown, the ceramic electric heater for the water tank includes a take-up housing, and an electric heating element 1 is inserted into the take-up housing. The electric heating element 1 is a ceramic heat conductor, and the ceramic heat conductor is specifically made of silicon nitride. The power is 400W ~ 10KW. The number of electric heating elements 1 using silicon nitride ceramics is usually one, or 2 to 4 in parallel.

[0022] The electric heating element 1 of the silicon nitride ceramic is that the conductive wire is encapsulated in the dense silicon nitride ceramic, and the silicon nitride ceramic is not only used as a heat conducting layer, but also as an insulating layer. Because silicon nitride ceramics have excellent insulation properties and thermal conductivity, and can resist the corrosion of acid and alkali solutions.

[0023] Specifically, the electric heating element 1 can adopt three forms, one is that the electric heating element 1 ...

Embodiment 2

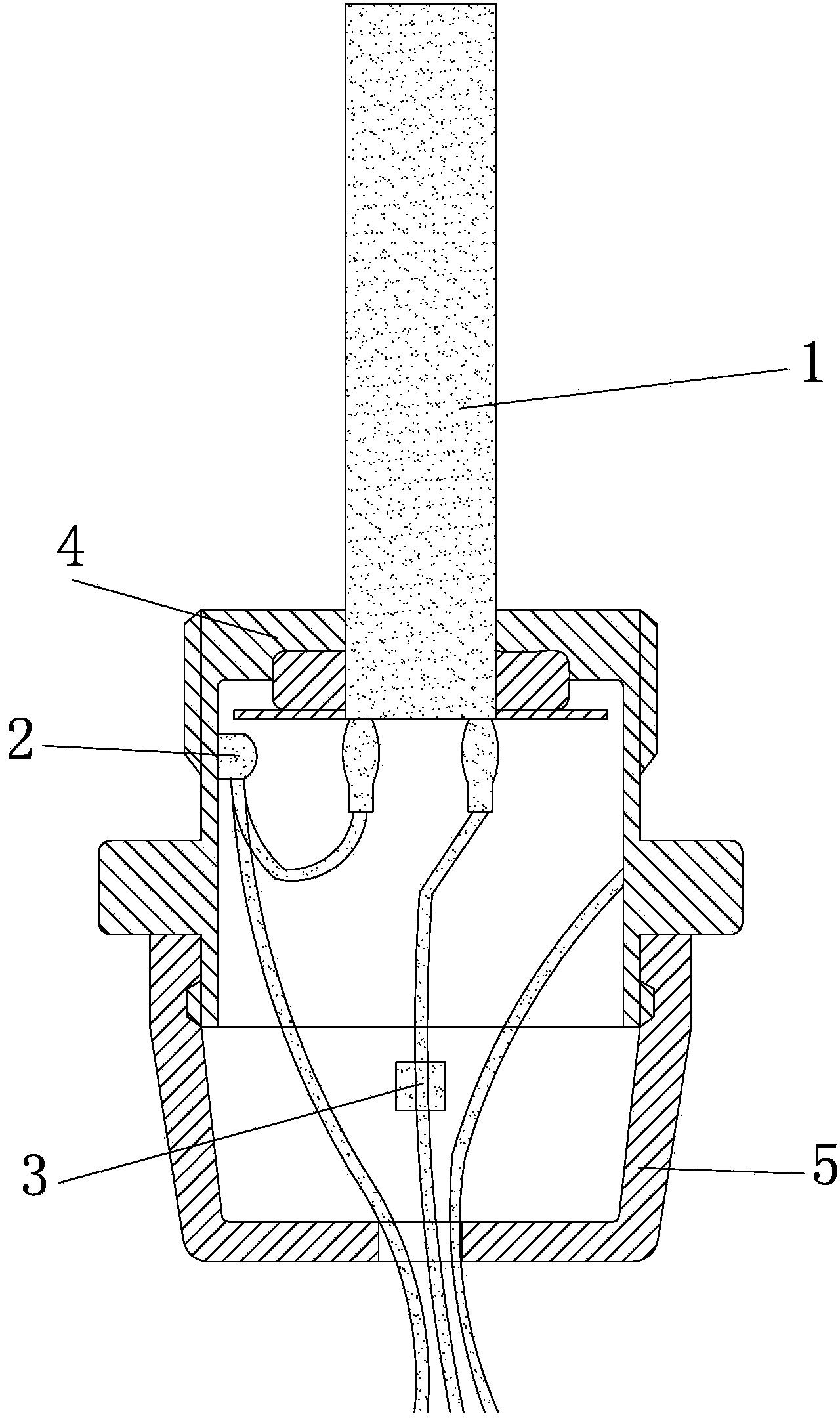

[0030] Such as figure 2 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that:

[0031] External threads are provided on the outer wall of the interface of the package base 4 , internal threads are provided on the inner wall of the interface of the back cover 5 , and the package base 4 and the back cover 5 form a threaded connection. This kind of thread assembly belongs to the flange type package seat 4, and the flange type package seat 4 with pipe thread has pipe thread specifications including 3 / 4 inch, 1 inch, 1.5 inch and 2 inch.

[0032]The ceramic electric heater for water tank uses silicon nitride ceramic electric heating element as the heating part, combined with over-temperature protection device, and is packaged in an easy-to-install plug or flange with pipe thread, which can be conveniently and firmly installed on the water tank. And high-density and high-strength silicon nitride has good th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Long axis | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap