Preparation method of canned shallot pickled product

A technology of pickled products and shallots, which is applied to the preparation of canned pickled products fermented with shallots as raw materials, and the preparation of canned wild vegetable pickles, to achieve unique flavor, crisp and tender texture, and high sensory evaluation scores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

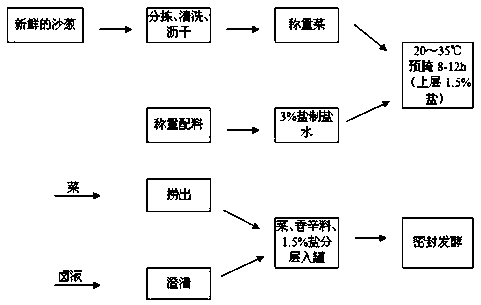

Method used

Image

Examples

Embodiment 1

[0028] Choose fresh green onions, remove mechanical damage, dry tails, old stems and other impurities in the vegetable body, wash and drain, weigh 500g into the container, add the prepared brine, where the water is 500ml, the salt The amount is 30g, and the top layer is sprinkled with 15g of salt. The temperature is controlled at 25°C for pre-marinating for 10 hours and then taken out. The liquid is clarified for use. Alternately put the pre-marinated green onion, one layer of vegetable, one layer of salt into the can, the amount of salt increases from bottom to top, the total amount of salt is 15g, and 25g of pepper, 3g each of Chinese pepper, ginger and fennel are added. The pre-marinated leaching clarified liquid is filled with the canned bottle, the canned bottle is sealed, and the temperature is controlled at about 20°C for natural fermentation.

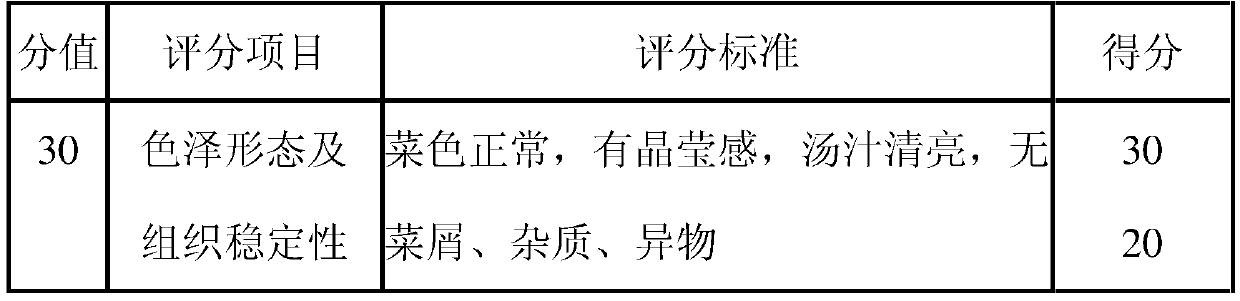

[0029] Sensory score results:

[0030]

Embodiment 2

[0032] Choose fresh green onions, remove mechanical damage, dry tails, old stems and other impurities in the vegetable body, wash and drain, weigh 450g into the container, add the prepared brine, of which the water is 550g, salt The amount is 30g, and the top layer is sprinkled with 15g of salt. The temperature is controlled at 25°C for pre-marinating for 12 hours and then taken out. The liquid is clarified for use. Alternately place the pre-marinated scallion with one layer of vegetable and one layer of salt into the can. The amount of salt increases from bottom to top. The total amount of salt is 15g. At the same time, add 25g of pepper, 2.5g each of Chinese pepper, ginger and fennel. Fill the canned bottle with the pre-marinated leaching clarified liquid, the canned bottle is sealed, and the temperature is controlled at about 20°C for natural fermentation.

[0033] Sensory score results:

[0034]

Embodiment 3

[0036] Choose fresh spring onions, remove mechanical damage, dry tails, old stems and other impurities in the vegetable body, wash and drain, weigh 400g into the container, add the prepared brine, of which the water is 600g, salt The amount is 30g, the top layer is sprinkled with 15g, and the temperature is controlled at 25°C for pre-marinating for 8 hours and then removed. The liquid is clarified for use. Alternately put the pre-marinated green onion, one layer of vegetable, one layer of salt into the can, the amount of salt increases from bottom to top, the total amount of salt is 15g, and at the same time add 20g of pepper, 2g each of Chinese pepper, ginger and fennel, and then add The pre-marinated leaching clarified liquid is filled with the canned bottle, the canned bottle is sealed, and the temperature is controlled at about 20°C for natural fermentation.

[0037] Sensory score results:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com