Copper anode plate casting mold with insert

A copper anode plate and casting mold technology is applied in the direction of casting molds, casting mold components, casting molding equipment, etc., which can solve problems such as microcracks, short service life of casting molds, and speed up the dissipation of heat from copper anode plates, so as to reduce production costs. The effect of extending the service life and accelerating the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

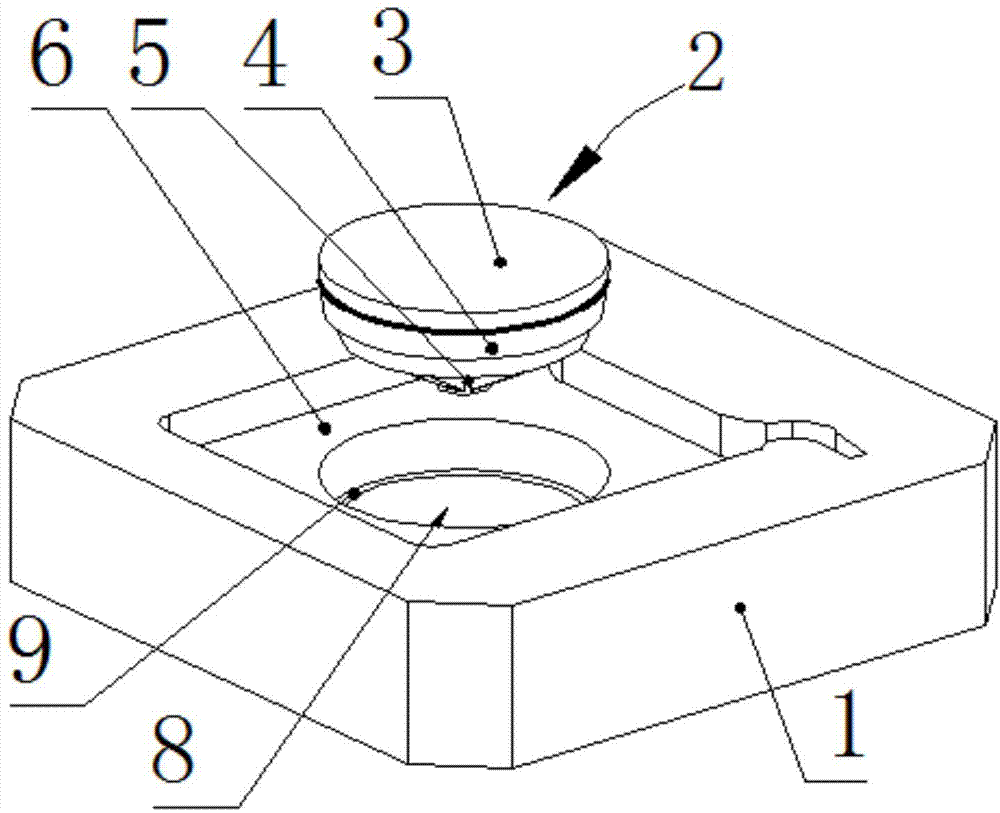

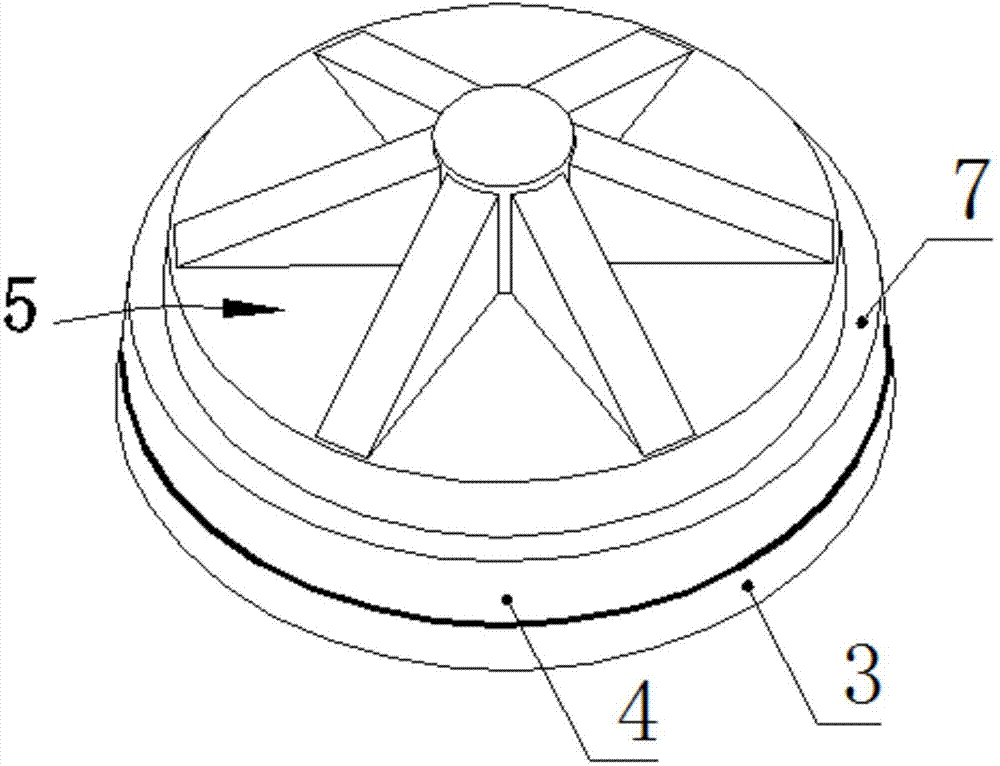

[0015] like figure 1 , figure 2 As shown, the copper anode plate casting mold with inserts includes a mold body 1, and a mold insert 2 that can be freely replaced in the middle of the mold body 1. The mold insert 2 is embedded in the insert hole 8 of the mold body 1, and the mold insert The block 2 includes a heat-resistant layer 3 and a cooling layer 4. The insert hole 8, the heat-resistant layer 3 and the cooling layer 4 are all provided with a draft angle of 3° to 5° to facilitate the placement or removal of the mold insert 2; the heat-resistant The thickness of layer 3 is 20-25mm. The heat-resistant layer 3 is made of high-temperature-resistant alloy material. The upper surface of the heat-resistant layer 3 is flush with the cavity surface 6 of the casting mold. The cooling layer 4 is made of ordinary steel and connected to the heat-resistant layer 3. below. In order to facilitate the cooling of the copper anode plate, a plurality of cooling grooves 5 are provided below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com