Hydraulic control system for log cutting machine

A technology of hydraulic control system and cutting machine, applied in the field of hydraulic control system, can solve problems such as cutter head stuck, immature research of hydraulic mechanism, motor burnt out, etc., to achieve improved cutting flatness, good steady-state control characteristics, and dynamic response fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

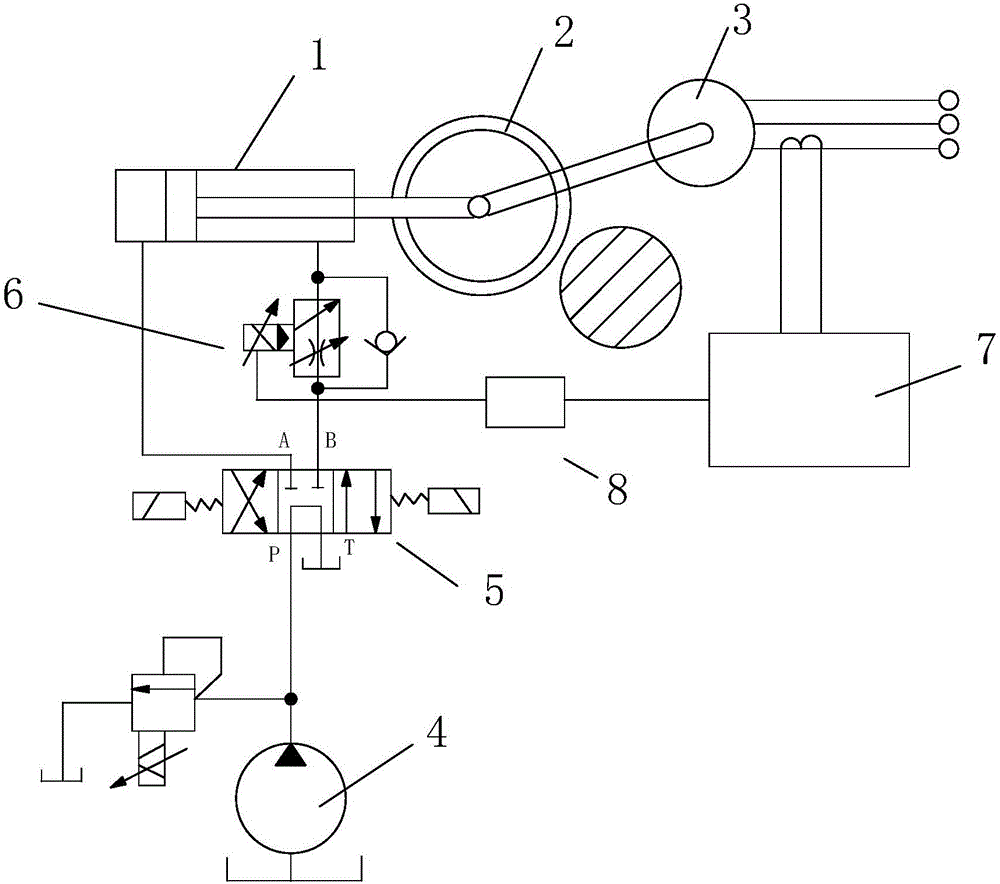

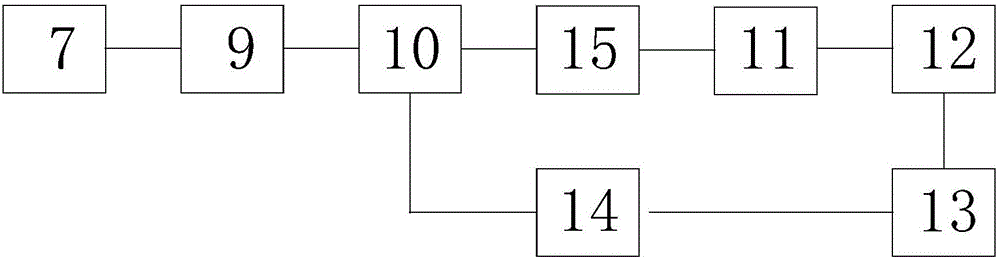

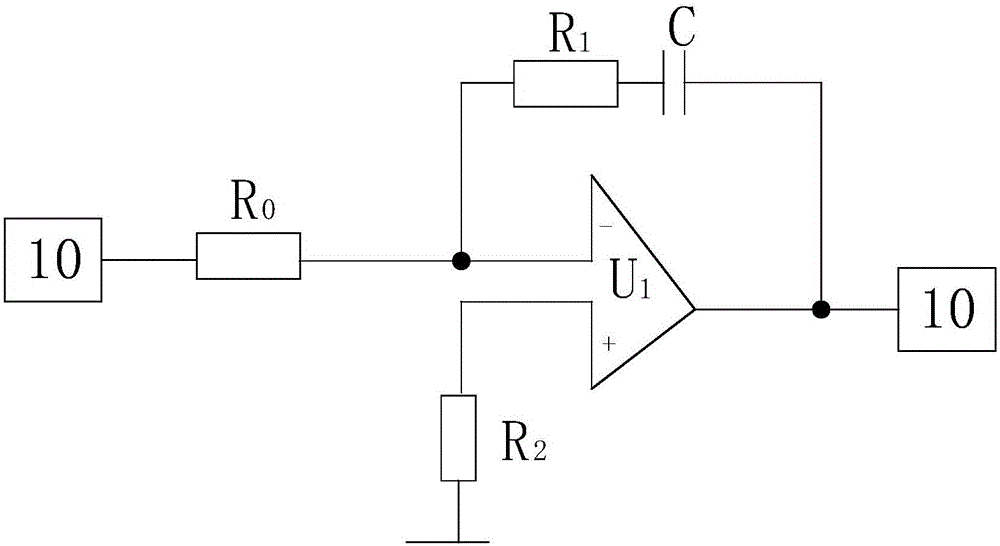

[0017] Embodiment: a kind of hydraulic control system for log cutting machine, as attached figure 1 and figure 2 As shown, it includes a mechanical mechanism and a hydraulic mechanism. The mechanical mechanism includes a cutting piston 1, and a cutting disc 2 is arranged on the extended end of the cutting piston 1. The cutting disc 2 is driven by a motor 3; the hydraulic mechanism includes Oil pump 4, oil pump 4 is connected with a three-position four-way solenoid valve 5 through the P oil circuit. The T oil circuit of the valve 5 is connected with the fuel tank; the B oil circuit is connected with a proportional speed regulating valve 6, and the signal output terminal of the proportional speed regulating valve 6 is connected with a proportional valve control amplifier 8 through a circuit, and the proportional valve control amplifier 8 is connected with a The electric controller 7 is connected to the motor through a circuit. The proportional valve control amplifier can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com