Prefabricated concrete square pile mold facilitating mold releasing

A technology of prefabricated concrete and square pile moulds, applied in the direction of moulds, manufacturing tools, mold auxiliary parts, etc., can solve problems such as damage to the health of workers, flying dust and noise pollution, cracks in concrete square piles, etc., to reduce flying dust and noise Pollution, reduced production cost, easy demoulding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

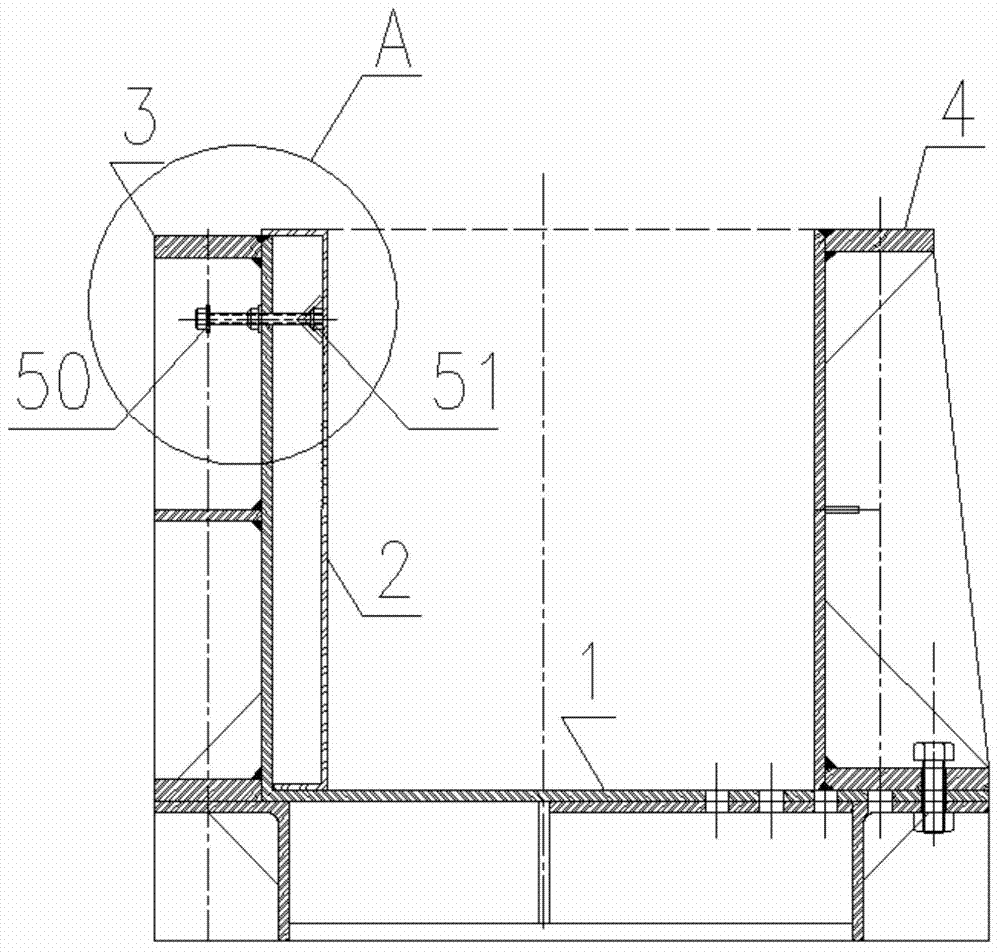

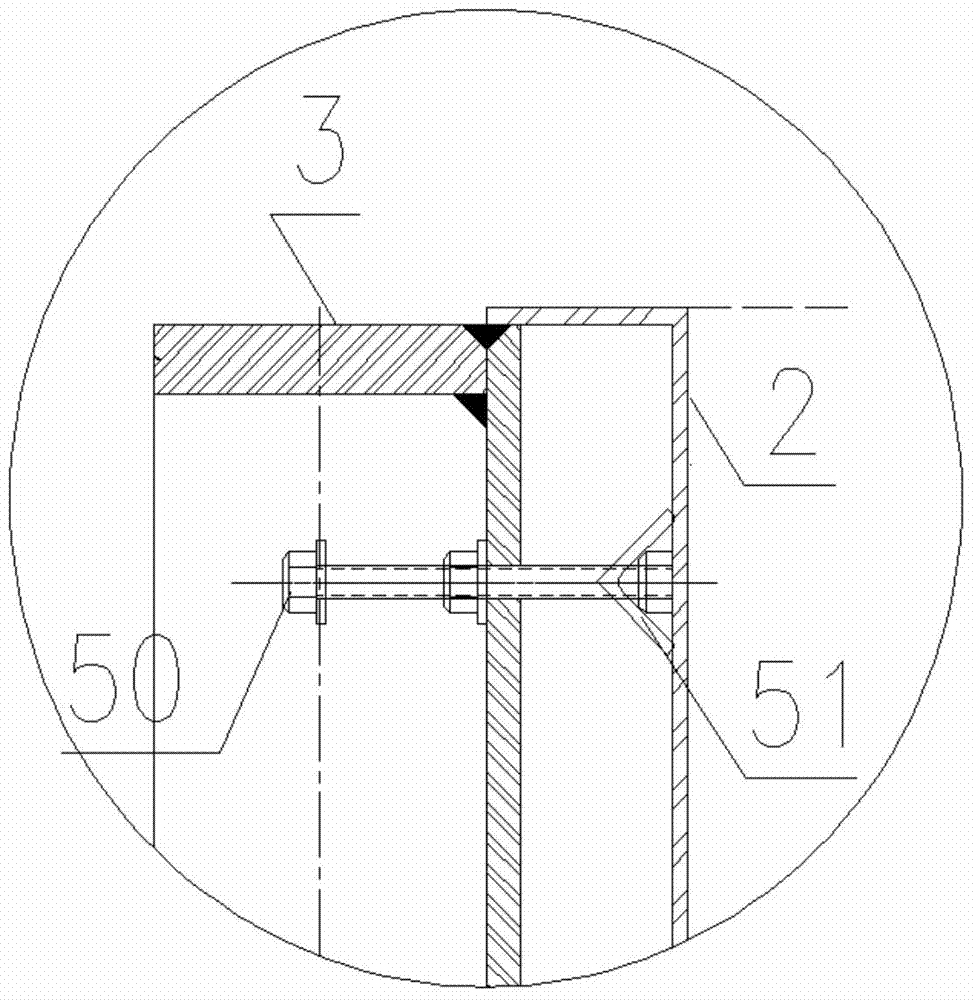

[0033] see figure 1 The easy-to-release precast concrete square pile mold of this embodiment is transformed from an existing adjustable precast concrete square pile mold, including a bottom formwork 1 and a support form vertically installed on the bottom formwork 1 Frame 3 and adjustable side template 4. The supporting mold frame 3 is exactly the fixed side formwork of the existing mould, and its shape and structure are all the same as the adjustable side formwork 4. However, in this embodiment, it only plays the role of strengthening the rigidity of the mold and supporting the shaping plate 2. Without contact with concrete mud, it does not have the shaping effect of general formwork.

[0034] The lower end of the supporting formwork 3 is fixedly welded to the bottom formwork 1, and the lower end of the adjustable side formwork 4 and the bottom formwork 1 are provided with corresponding installation holes, wherein there are multiple sets of installation holes on the bottom fo...

Embodiment 2

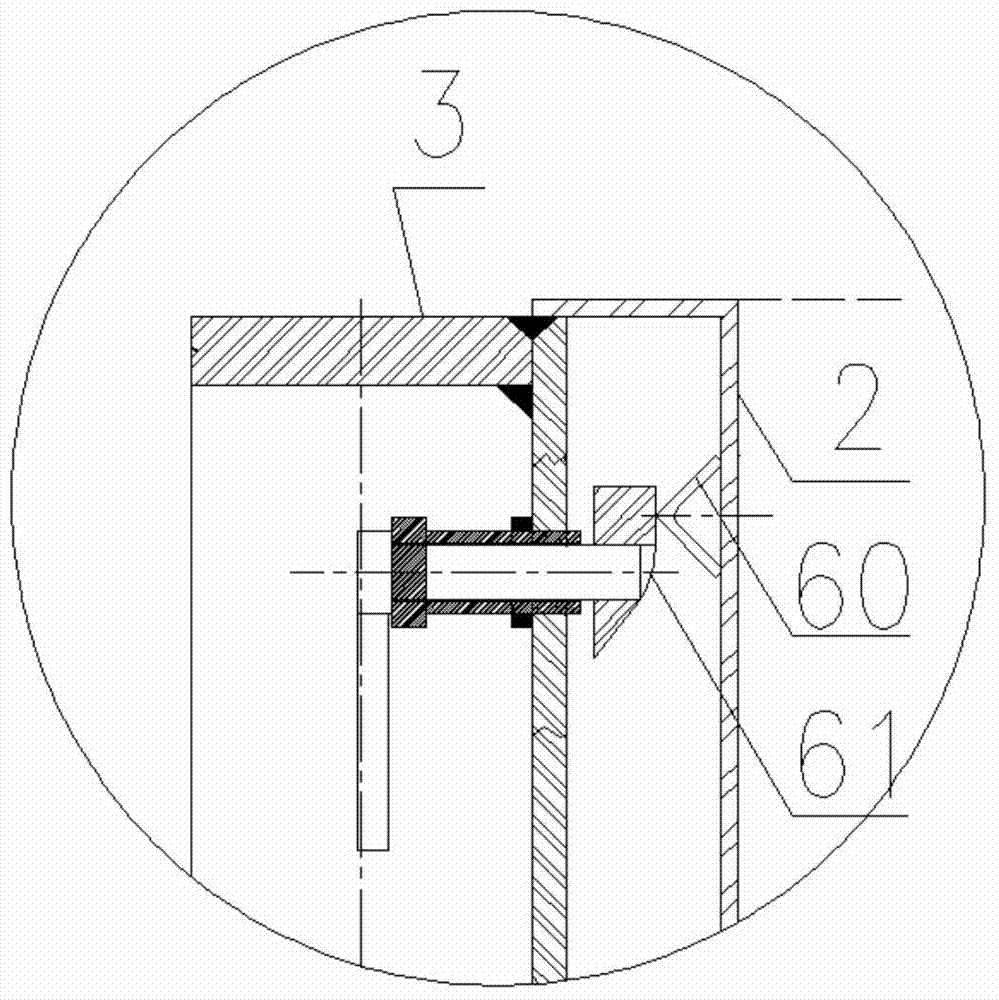

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the adjustable side formwork 4 in Embodiment 1 is also transformed into the adjustable supporting mold frame provided with the shaping plate positioning device in Embodiment 1. The inner side of the adjustable support mold frame also increases a molded plate with the same shape and material as the molded plate 2 in Embodiment 1, and the installation folding surface of the molded plate is provided with the installation of the adjustable support mold frame. The same installation hole as the hole, and the shaping plate and the adjustable support mold frame are installed on the bottom formwork 1 together with bolts. In this way, the adjustable support formwork, that is, the original adjustable side formwork 4 after transformation, is also the same as the support formwork 3 in this embodiment, and only plays the role of strengthening the rigidity of the mold and supporting the shaping plate without ...

Embodiment 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 2 is only the change of the structure of the supporting formwork. This embodiment does not use the adjustable side formwork or the fixed side formwork of the existing mold as the support formwork, but uses two The strip is equal to the length of the bottom formwork 1, and the upper and lower channel steels arranged in parallel are used as the support formwork on both sides, and the upper and lower channel steels on each side are welded with reinforcing steel plates at intervals. The supporting mold frame composed of channel steel is not only convenient to manufacture and has high strength, but also facilitates the operation and adjustment of the mold due to the gaps left between the channel steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com