Additive compositions with plural friction modifiers

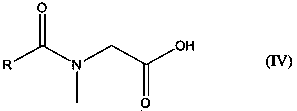

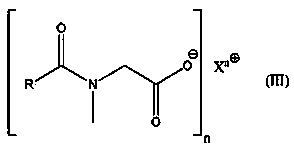

A friction modifier, additive package technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve problems such as harmful film friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

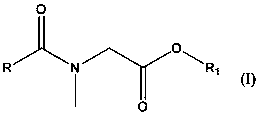

[0310] Embodiment 1: Butyl oleoyl sarcosinate (BuOS)

[0311] 281 g (0.8 mol) oleoyl sarcosine, 237 g butanol and 0.38 g Amberlyst 15 acid resin were added to a 500 mL resin kettle equipped with overhead stirrer, Dean Stark separator and thermocouple. The reaction mixture was heated at reflux under nitrogen with stirring for 3 hours, removing 25 mL aliquots every 30 minutes. The reaction mixture was then concentrated under vacuum and filtered to obtain 310 g of product.

Embodiment 2

[0312] Embodiment 2: Ethyl oleoyl sarcosinate (EtOS)

[0313] 281 g (0.8 mol) oleoyl sarcosine and 295 g ethanol were added to a 500 mL resin kettle equipped with overhead stirrer, Dean Stark separator and thermocouple. The reaction mixture was heated at reflux under nitrogen with stirring for 3 hours, removing 25 mL aliquots every 30 minutes. The reaction mixture was then concentrated under vacuum to obtain 280 g of product.

Embodiment 3

[0314] Example 3: Ethyl lauroyl sarcosinate (EtLS)

[0315] 128.5 g (0.5 mol) lauroyl sarcosine and 345.5 g ethanol were added to a 500 mL resin pot equipped with overhead stirrer, Dean Stark separator and thermocouple. The reaction mixture was heated at reflux under nitrogen with stirring for 3 hours, removing 25 mL aliquots every 30 minutes. The reaction mixture was then concentrated under vacuum to obtain 126.2 g of product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com