Process for producing laser simulated jacquard-imitated textile composite fabric

A composite fabric and production process technology, applied in textile decoration, textile and papermaking, fabric surface trimming and other directions, can solve the problems of easy shrinkage, rapid decline in strength of polyester fabric, monotonous color of etching and engraving, etc., and achieve gradient three-dimensional unevenness Strong visual sense of perspective, high degree of fineness of pattern, and the effect of guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

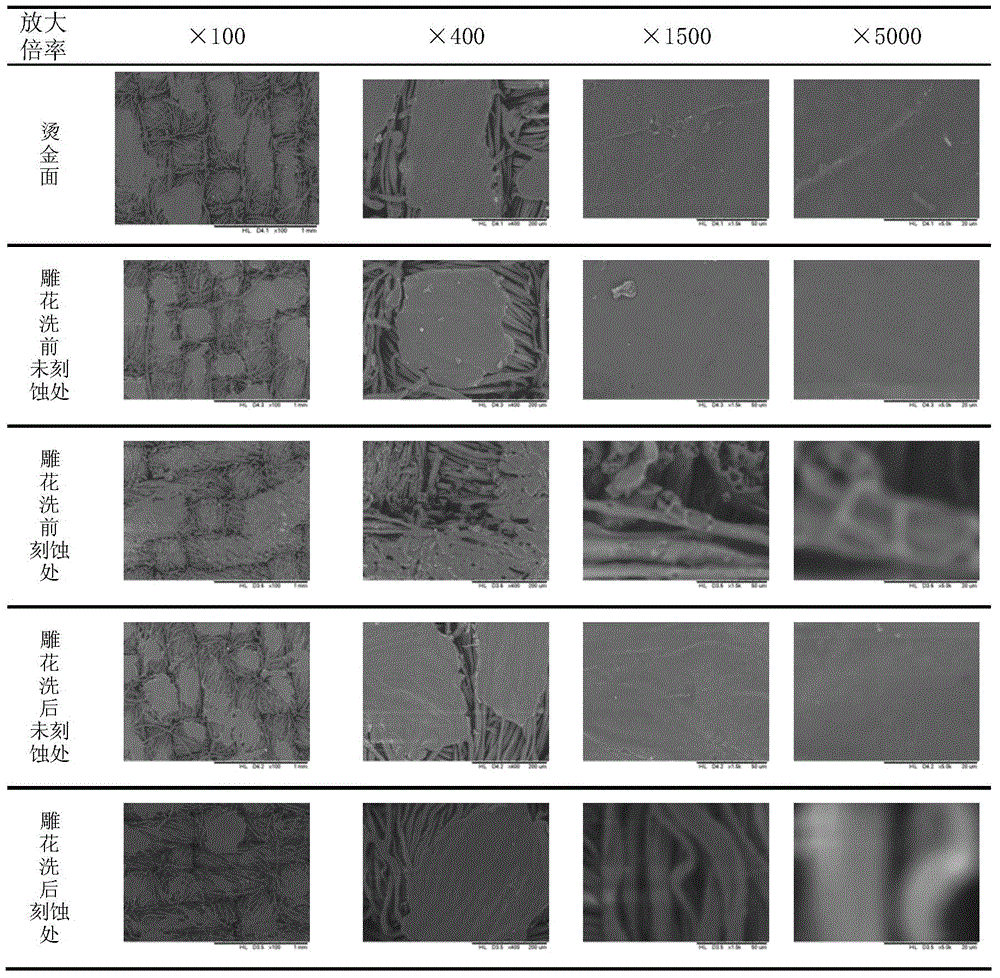

[0103] The front engraving production process of cotton elastic general yellow bottom magic color laser imitation jacquard textile composite fabric is completed by the front etching process.

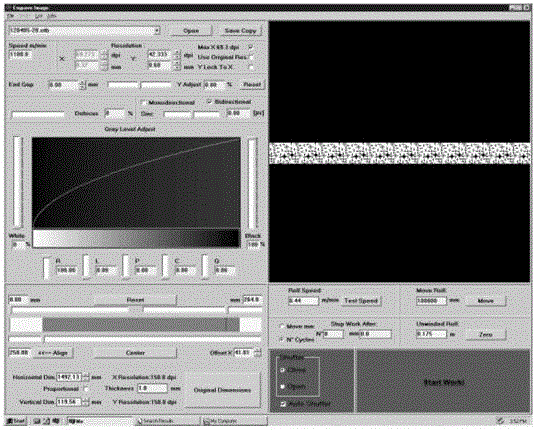

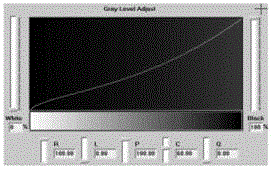

[0104] Figure 6 It is the 120405-20.otb general yellow magic color bottom carved pattern of this embodiment, Figure 7 Adjusts the quadratic curve for the laser engraved gray scale corresponding to the pattern.

[0105] A: Put the roll of polyester T / cotton C twill general yellow cloth face up and place it on the laser engraving machine;

[0106] B: Set and adjust the pattern on the laser engraving machine

[0107] I. Pattern design:

[0108] ① The four directions of pattern texture have scattering effect;

[0109] ②The area of the pattern line can be adjusted in black, white, and gray, and it seems to have a sense of gradient perspective;

[0110] ③Because the polyester T / cotton C base fabric is easy to fall and become strong in the weft direction, the engraved area of the pat...

Embodiment 2

[0124] The base fabric for engraving in this embodiment is a roll of non-elastic corduroy white cloth, and the object of engraving is a non-elastic corduroy white bottom phantom color laser imitation jacquard textile composite fabric

[0125] A: Put the non-stretch corduroy white cloth roll face up and place it on the open-width dynamic continuous laser engraving machine;

[0126] B. Set and adjust the pattern on the laser engraving machine

[0127] Graphic design:

[0128] ①The pattern has obvious concave-convex texture;

[0129] ②The black and white lines and areas of the pattern are distinct, and the gray scale does not change gradually;

[0130] ③Because the surface of corduroy is endowed with plump fluff, a clear and regular flower pattern was chosen.

[0131] Based on the above pattern design ideas, the following Figure 8 As shown in the .BMP file of the white phantom bottom carving pattern, and obtain the laser engraving grayscale adjustment quadratic curve corres...

Embodiment 3

[0142] Embodiment 3, the base cloth of the present embodiment is a bronzing base cloth with cotton elastic blue background.

[0143] A: Place the bronzing cloth roll with cotton elastic blue background on the open-width dynamic continuous laser engraving machine with the front facing up;

[0144] B: Set and adjust the pattern on the laser engraving machine

[0145] I. Pattern design ideas:

[0146] ①The pattern has a complete line outline texture;

[0147] ②The area of the pattern line can be adjusted in black, white, and gray, and it seems to have a sense of gradient;

[0148] ③Because the surface of the bronzing cloth has a good metallic luster, a thick arc line pattern with a small overall unit area is selected.

[0149] Based on the above pattern design ideas, the following Figure 10 The .BMP file of the engraved pattern on the hot stamping surface is shown, and the laser engraved grayscale adjustment quadratic curve corresponding to the pattern is obtained, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com