An adjustable gob-side entry retaining wall and its construction method for active support and then pressure support

A construction method and an adjustable technology, which is applied in the direction of earthwork drilling, pillars/brackets, mining equipment, etc., can solve problems such as inability to provide active support, difficult sideways movement of walls, and large subsidence of roadway roofs, etc., to achieve The construction operation is easy to operate, the height of the wall can be adjusted, and the supporting structure is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

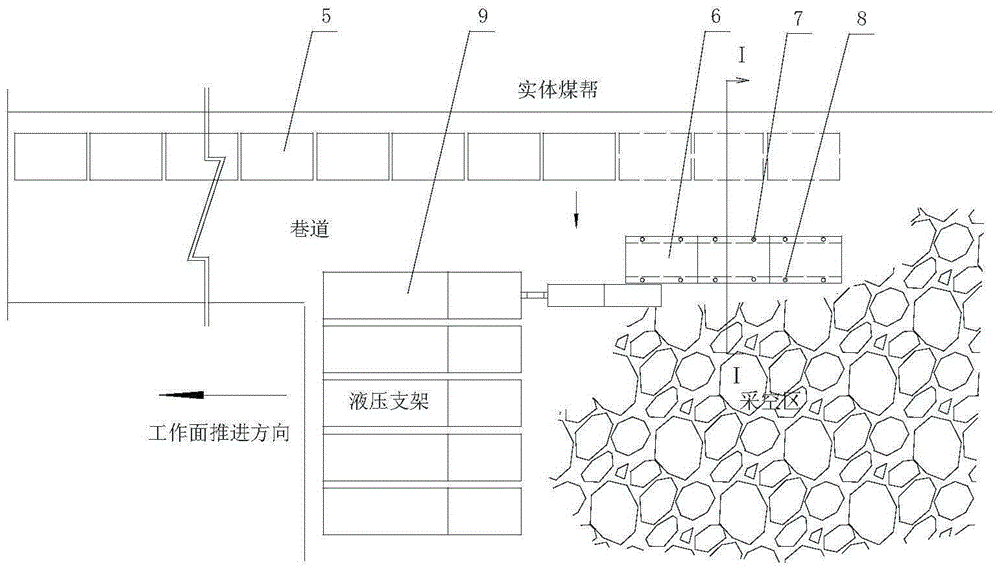

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

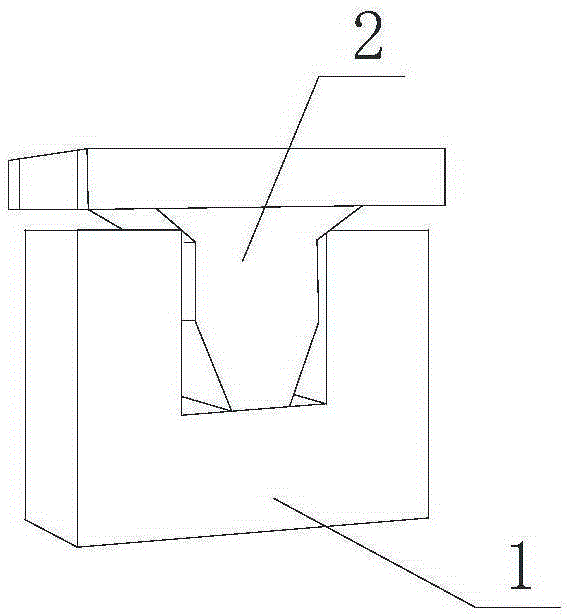

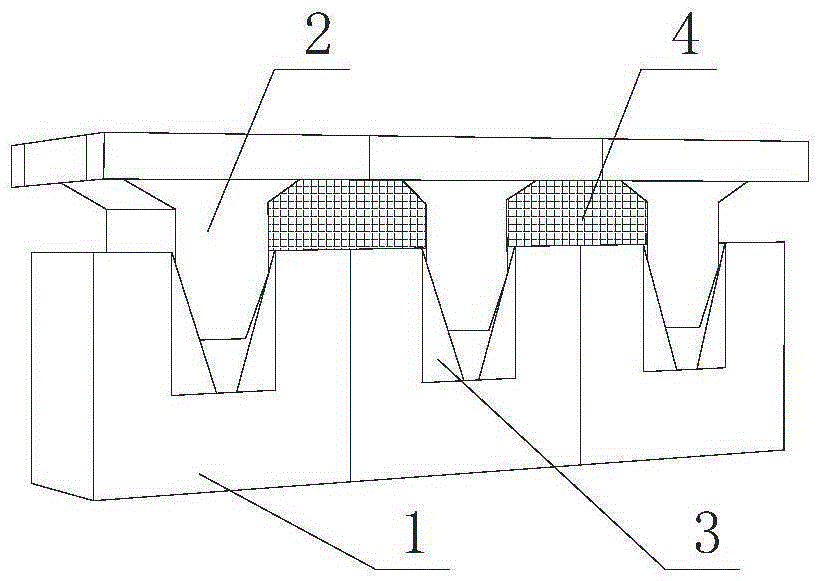

[0048] Such as figure 1 , figure 2 As shown, the adjustable gob-side entry retaining wall of the present invention, which is active first and then yielded, includes a seat block 1, a lifting support block 2, a friction yield block 3 and a shrinkable yield block 4; wherein, the seat block 1 is a concave structure;

[0049] The lifting support block 2 is a T-shaped structure, and the width of the horizontal part of the T-shaped structure of the lifting support block 2 in the front and rear directions is greater than the width of the seat block 1 in the front and rear directions;

[0050] Friction allows the shape of the briquetting block 3 to be a right triangle;

[0051] The two side surfaces of the lower section of the vertical part of the lifting support block 2 are conical surfaces. The vertical part of the T-shaped structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com