Brake mechanism of hard hose traveler

The technology of a brake mechanism and sprinkler irrigation machine is applied in the direction of brake actuators, gear shifting mechanisms, mechanical equipment, etc. It can solve the problems of inconvenient operation and the inability to implement linkage between the gear lever and the brake lever, etc., and achieves simple production, low cost, The effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

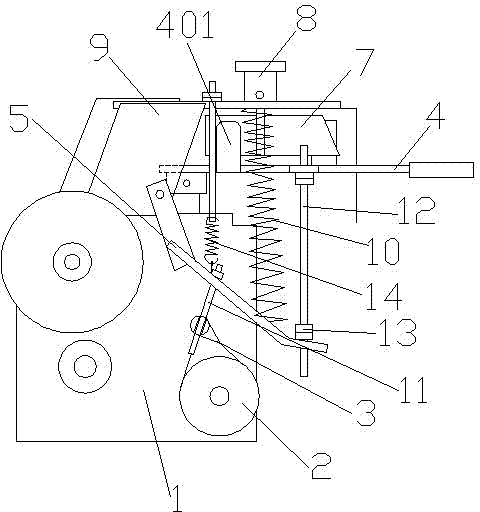

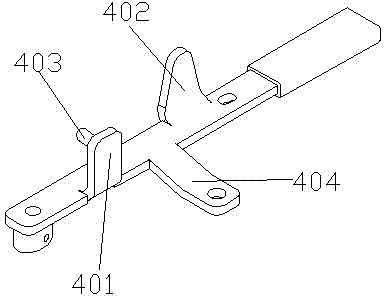

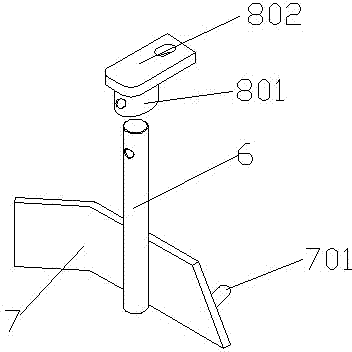

[0015] Such as Figure 1 to Figure 3 As shown, a specific embodiment of the present invention includes a gearbox 1, a brake wheel 2, a brake band 3, a shift lever 4, a brake link 5 and a swing arm assembly, and the swing arm assembly includes a swing shaft 6, a swing arm 7 and a rocker arm 8, the rocker arm 8 includes a sleeve 801 and a pull plate 802 fixed on the top of the sleeve 801, the upper end of the gearbox 1 is provided with a bracket 9, the bracket 9 shown in Figure 1 includes a bracket fixed on The vertical plates on both sides of the gearbox 1 and the horizontal plate fixed between the two vertical plates, the lower end of the swing shaft 6 is fixed on the middle part of the swing arm 7, and a through hole is arranged on the horizontal plate of the bracket 9. The swing shaft 6 is fixedly connected with the sleeve 801 of the rocking arm 8 after passing through the through hole on the horizontal plate (the top of the swing shaft 6 is provided with a through hole, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com