Water-saving anti-freezing device for indirect air-cooled light steel frame structure tower

An anti-freezing device and air-cooling technology, applied in the field of cooling towers, can solve problems such as large water resources, equipment damage, and consumption, and achieve the effects of saving water resources, preventing freezing, and reducing draft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

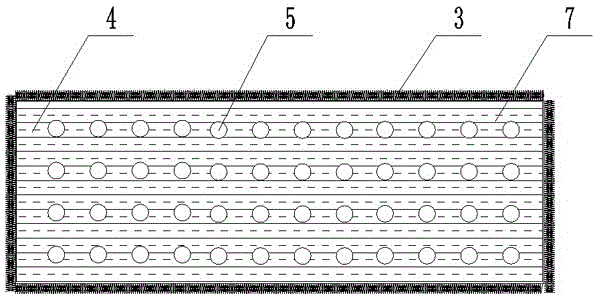

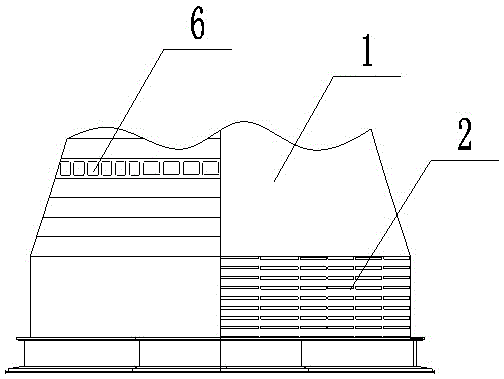

[0020] Such as Figure 1 ~ Figure 4 As shown, the water-saving antifreeze device used in the indirect air-cooled light steel frame structure tower of the present invention includes a water-saving antifreeze device body 1 and a heat exchange tube bundle 2, and the water-saving antifreeze device body 1 is composed of a circle of heat exchange tube bundles 2, The heat exchange tube bundle 2 is formed by end-to-end connection of a plurality of heat exchange tube bundle units 4, and each heat exchange tube bundle unit 4 includes a plurality of heat exchange tubes 5, and the heat exchange tubes 5 are vertically arranged in the heat exchange tube bundle In the unit 4, the outer wall of the heat exchange tube bundle unit 4 is provided with a plurality of heat exchange fins 3, and the space between the heat exchange tube bundle unit 4 and the heat exchange tubes 5 is filled with circulating water 7 for cooling;

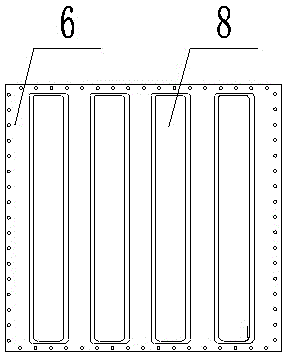

[0021] A plurality of ventilation skylights 6 are movably arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com