Method and device for measuring high-temperature and high-pressure wet steam flow

A high-temperature, high-pressure, wet-steam technology, applied in measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as difficult stability of calculation results, sensitive two-phase flow flow state, and difficult separation technology, etc., to achieve The effect of low cost, simple process and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

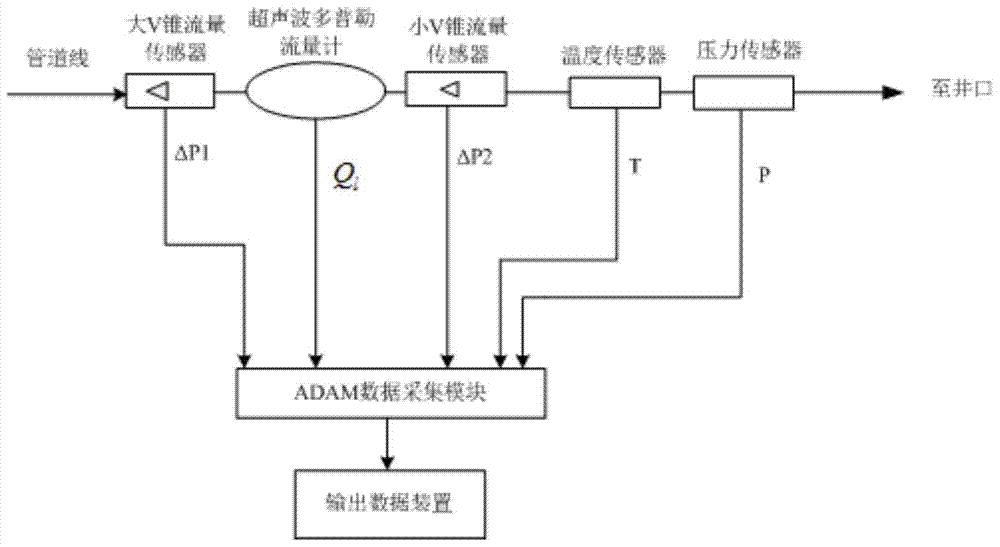

[0017] The device and method for measuring the flow of wet steam according to the present invention will be described in detail below according to the diagrams.

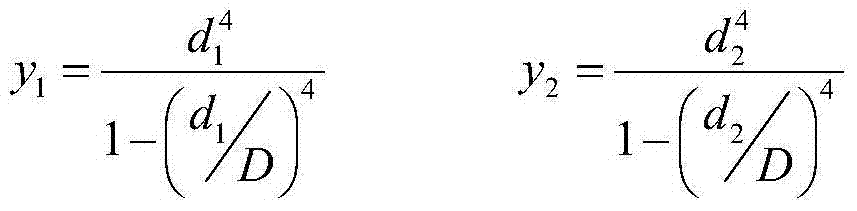

[0018] Wet steam flows into the pipe along the direction shown in the figure, when the diameter of the flow is d 1 A large V-cone flowmeter will produce a pressure drop Δp due to resistance 1 , is transmitted through the pressure transmitter, and the continuity equation and Bernoulli equation are used for the section before the fluid flows into the large cone and when it flows into the cone. The formula is as follows:

[0019] ρ 0 A 0 V 0 = ρ 1 A 1 V 1

[0020] Z 0 = V 0 2 g + p 0 ρ 0 g = Z 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com