Device for realizing opposed two-stroke cylinder sleeve flow test

A technology of cylinder liner and test bench, which is applied in the direction of measuring device, internal combustion engine test, engine test, etc., can solve the problems of inability to test gas flow performance, etc., and achieve the effect of simple structure, convenient use and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

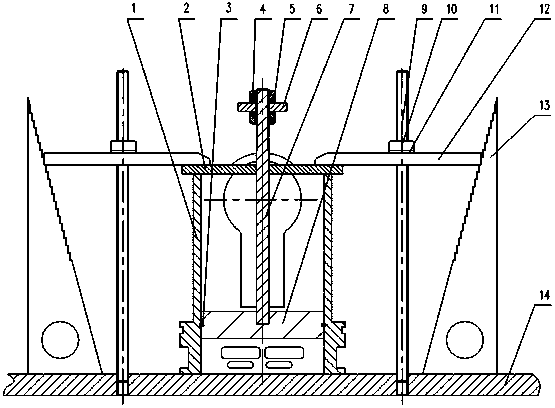

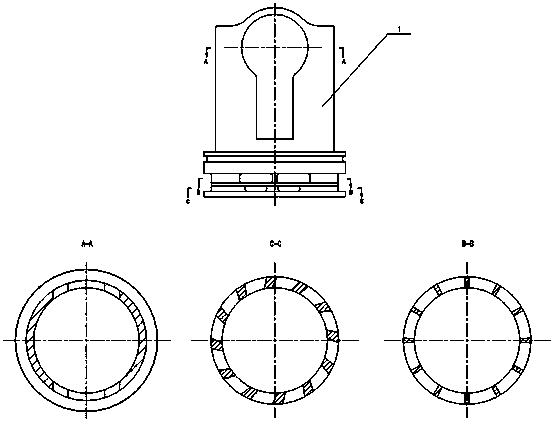

[0027] Below in conjunction with accompanying drawing, the present invention will be further described.

[0028] A device for realizing the air flow test of opposed two-stroke cylinder liners according to the present invention, comprising a cylinder liner (1), a support plate (2) with threaded holes, a rubber ring (3) with a diameter of 3 mm, bolts (4), lock washer (5), handle (6), single-headed stud (7), plunger (8), double-ended stud (9), bolt (10), washer (11), A pressing plate (12), a support block (13), and a test bench top (14) with threaded holes.

[0029] The cylinder liner (1) is located on the test bench (14), and there is a plunger (8) inside the cylinder liner (1) that matches the inner diameter of the cylinder liner (1); it is used to ensure that the plunger (8) is in contact with the cylinder liner ( 1) The rubber ring (3) with no air leakage in the gap between them is located in the ring groove of the cylindrical surface of the plunger (8); there is a hole on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com