Magnetoelectric velocity transducer with self-checking function

A speed sensor, magnetoelectric technology, applied in the direction of speed/acceleration/shock measurement, instrument, testing/calibration of speed/acceleration/shock measurement equipment, etc. Normal, speed sensor use, inconvenient detection, unfavorable failure prevention and other problems, to achieve the effect of mass production, compact structure, and modular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

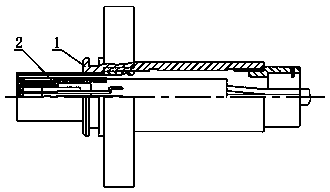

[0025] Such as figure 2 The magnetoelectric speed sensor with self-checking function shown includes a casing 1 and an inner core assembly 2 placed inside the casing 1 .

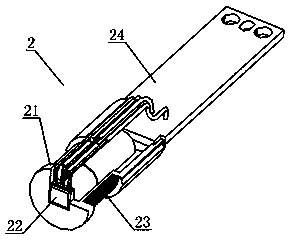

[0026] The structure of inner core assembly 2 is as image 3 , Figure 4 As shown, the inner core assembly 2 includes a connecting bracket 21, a Hall element 22, a coil 23, a circuit board 24, a magnetic steel 25, an iron core 26 and connecting lines.

[0027] The connecting bracket 21 is composed of three sections. The three sections are the induction element mounting base 211, the cylindrical coil frame 212, and the cylindrical mounting bracket 213. The connecting bracket 21 is made in one piece. There is a mounting groove on the sensing element mounting base 211, and the Hall element 22 is embedded in the mounting groove, so as to facilitate and accurately locate the installation position of the Hall element 22 and ensure the overall sensing distance of the product; The inside of the skeleton 212 is a ...

Embodiment 2

[0037] The Hall element 22 in the first embodiment is replaced by a sensitive element based on the magnetoresistance effect, and other structures and principles are the same as those in the first embodiment. When measuring speed, the sensitive element based on the magnetoresistance effect can sense the change of the magnetic field caused by the rotation of the gear, and output a square wave signal related to the gear speed through signal processing; The alternating magnetic field generated by the functional module outputs a square wave signal through signal processing.

Embodiment 3

[0039] A Hall speed sensor with a self-checking function, using a Hall element integrated with a magnet to replace the Hall element 22 in the first embodiment, the integrated magnet can replace the magnet 25 in the first embodiment, the integrated magnet The permanent magnet provides a magnetic field for speed measurement, so the magnetic steel 25 in the inner core assembly 2 of the first embodiment can be omitted, and other structures and principles are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com