Holed side wall type upper vacuum chamber system of fountain atomic clock

A technology of vacuum chamber and opening type, which is applied in the field of vacuum chamber system on fountain atomic clock with opening on the side wall, which can solve the problems of difficult adjustment of microwave system, difficulty of preparation and maintenance of vacuum environment, and large volume, and achieve reduction Effects of volume, difficulty reduction, and reduction in the circumference of the sealing ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

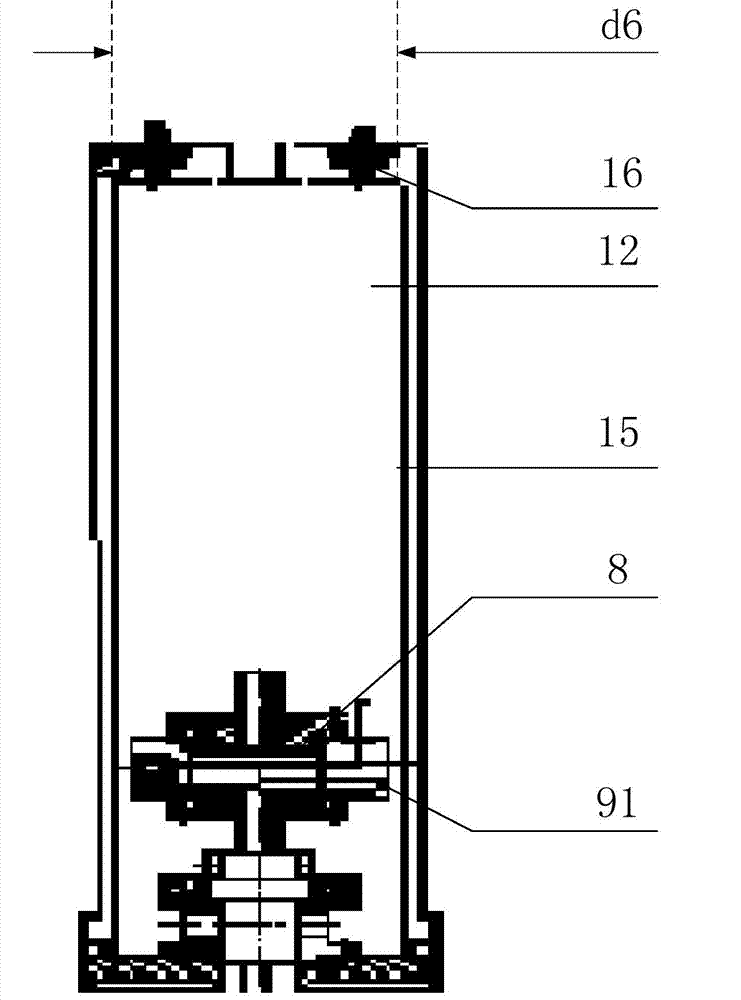

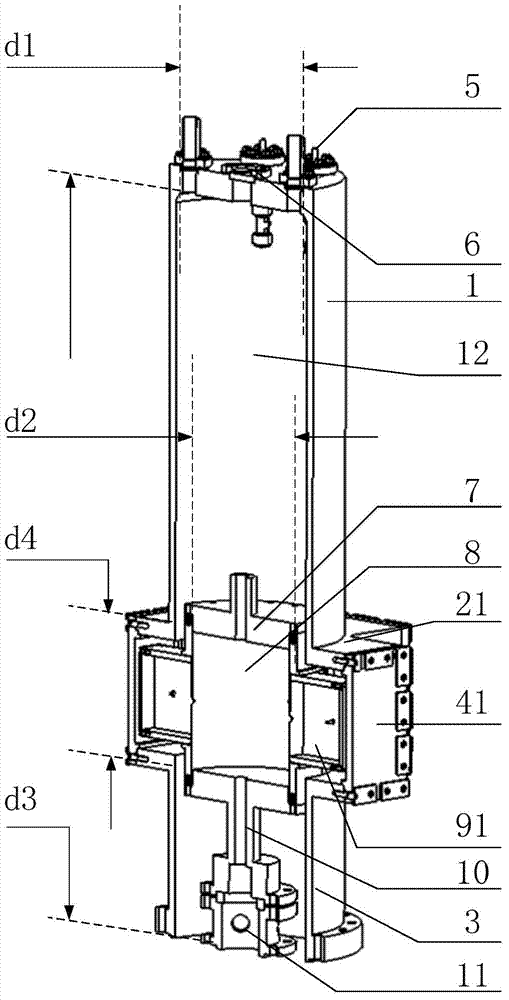

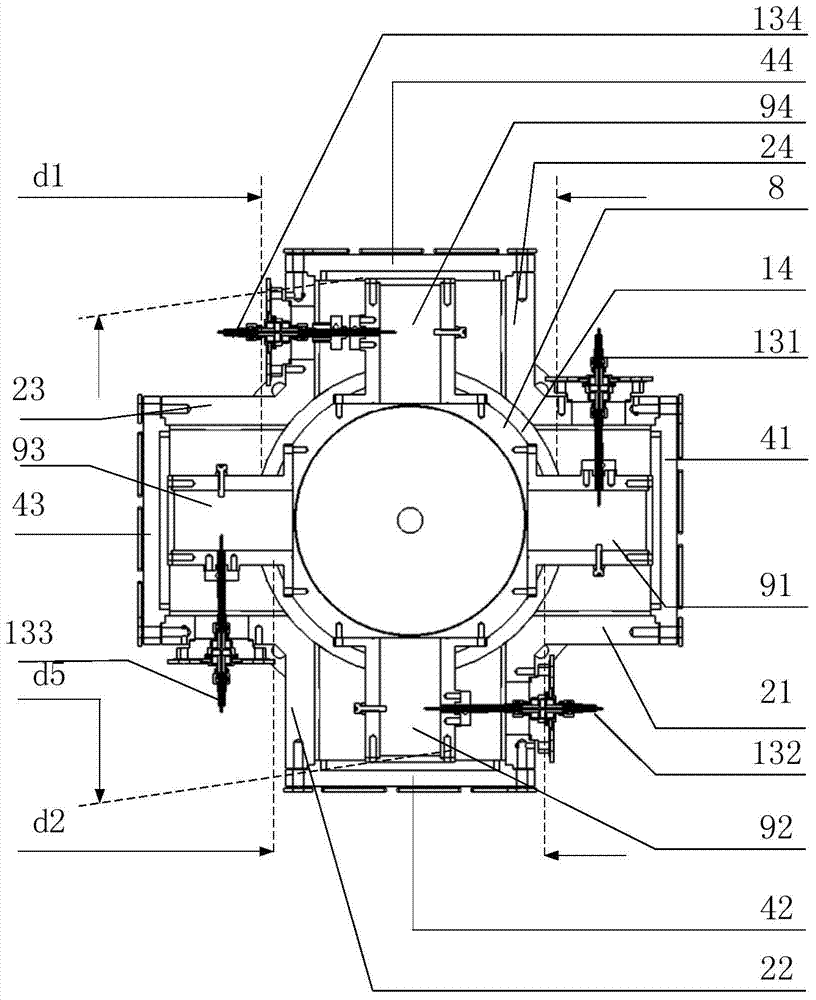

[0020] refer to figure 2 with image 3 , the upper vacuum chamber system of the present invention's side wall opening type fountain atomic clock includes a vacuum chamber wall 1 in the free flight area of cold atoms, a microwave chamber 8, four rectangular convex holes 21, 22, 23, 24 of the microwave chamber 8, and a lower vacuum chamber. The vacuum chamber wall 3 of the chamber connection part 10, 11, the sealing covers 41, 42, 43, 44 of the four rectangular convex holes, the vacuum flange 5, and the sealing glass window 6 are characterized in that:

[0021] The vacuum cavity wall 1 in the cold atom free flight zone is a cylindrical cavity wall, the value of its diameter d1 depends on the diameter d2 of the microwave cavity upper cover 7, and is not affected by the siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com