Method for detecting multi-period oscillation behaviors of industrial control loops

A technology of industrial control and detection method, which is applied in the direction of electrical testing/monitoring, etc., can solve the problems of poor fitting of non-stationary signals, high computational complexity, and non-representative oscillation component signals, etc., so as to improve detection accuracy and Reliability and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

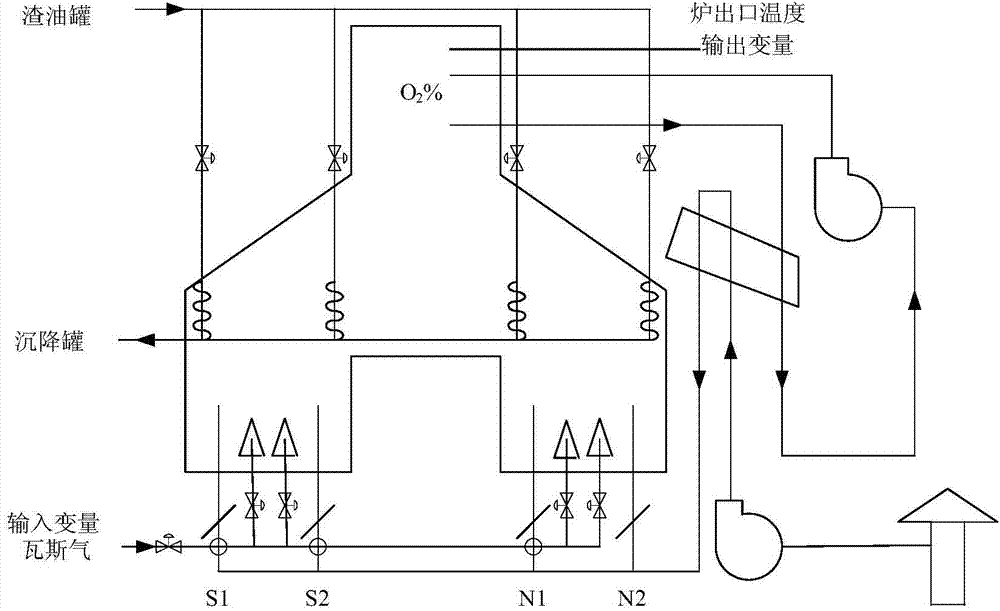

[0069] Taking the performance evaluation of the main heating furnace in the delayed coking production process of a large domestic petrochemical enterprise as an example, the multi-cycle oscillation behavior detection method of the chemical process with the control valve viscous characteristic of the present invention will be described in detail below.

[0070] like image 3 As shown, the petrochemical process heating furnace is an important link in the production process and one of the main energy-consuming units. The stable control of the furnace outlet temperature is of great significance for improving product quality and reducing energy consumption.

[0071] The heating furnace obtains heat through the supply of gas, and the amount of gas fluctuates according to the change of upstream oil properties. It is necessary to control the air intake to make the gas fully combust to obtain the maximum heat. At the same time, a certain air margin should be ensured, but too much low-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com