Electrode assembly, manufacture method thereof and lithium secondary battery

A technology of an electrode assembly and a manufacturing method, which is applied in the direction of secondary batteries, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low material utilization rate, large battery volume, high manufacturing and use costs, and achieve low production equipment requirements, Effect of improving energy density and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described in detail below:

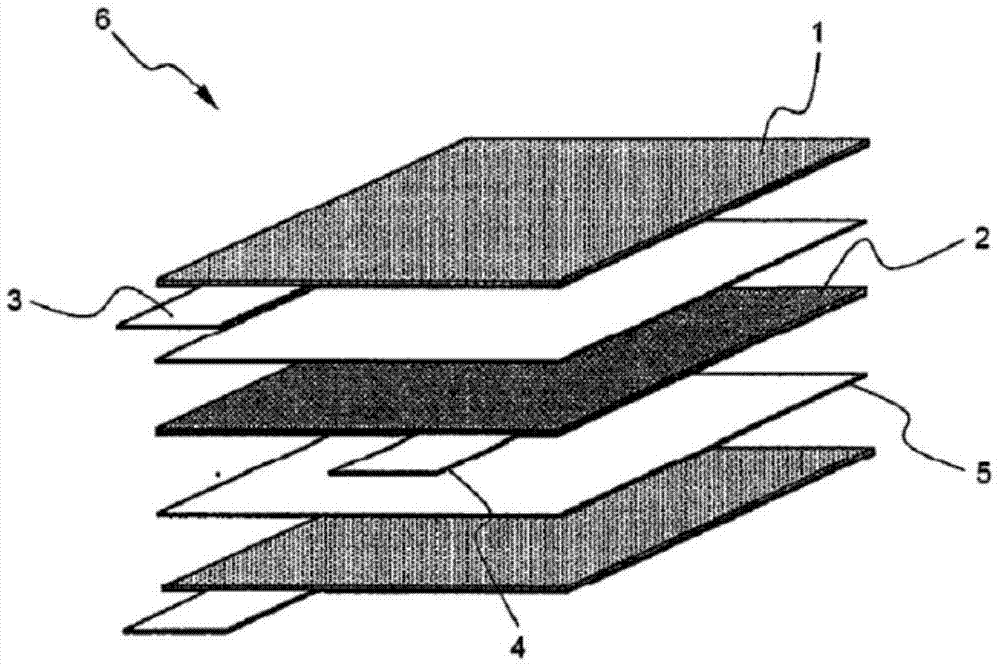

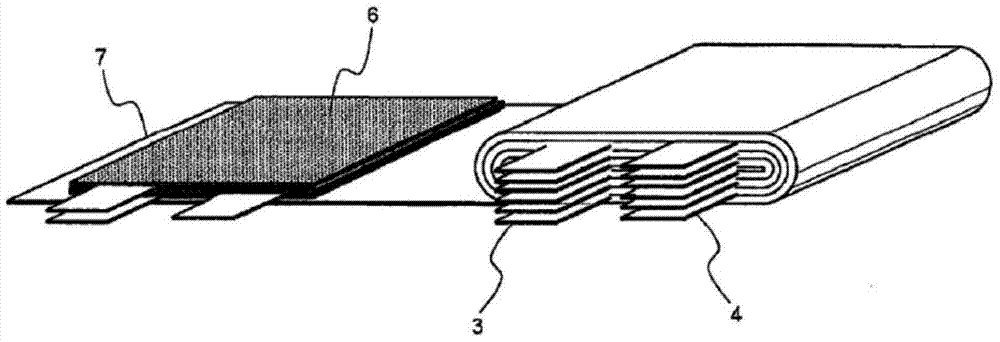

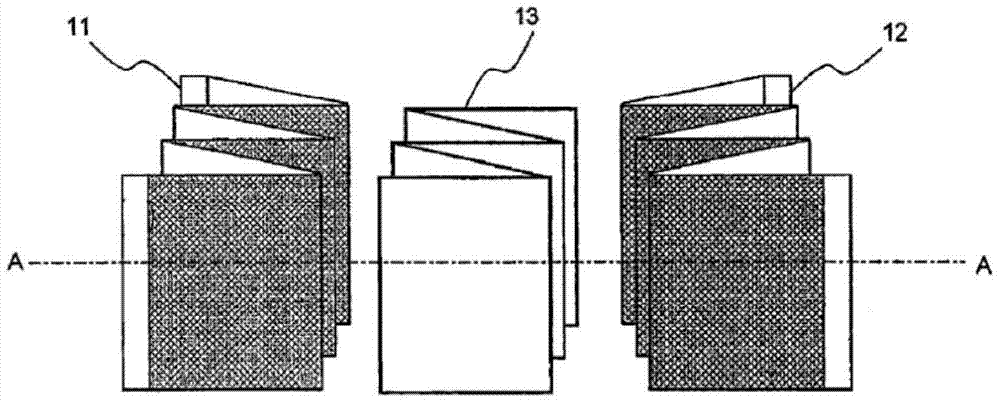

[0041] Such as Figure 4 , 5As shown, an electrode assembly provided by the present invention includes a first pole plate 21 and two second pole plates 22, both sides of the first pole plate 21 are coated with an active material layer 26, and the first pole plate 21 is coated with an active material layer 26. One pole plate 21 is continuously bent along the length direction of the first pole plate 21 into a zigzag vertical section. One side of the second pole plate 22 is coated with an active material layer 26, and the second pole plate 22 is continuously bent into a zigzag vertical section along the length direction of the second pole plate 22. The two surfaces coated with the active material layer 26 of the pole plate 21 are respectively opposite to the surfaces coated with the active material layer 26 of the two second pole plates 22 , and between the first pole plate 21 and the second pole plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com