Black tea processing method

A processing method and technology for black tea, applied in the processing field of black tea, can solve the problem that the odor is not as mellow and mellow, and achieve the effects of high and long-lasting aroma, bright copper red soup color, and obvious rock charm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

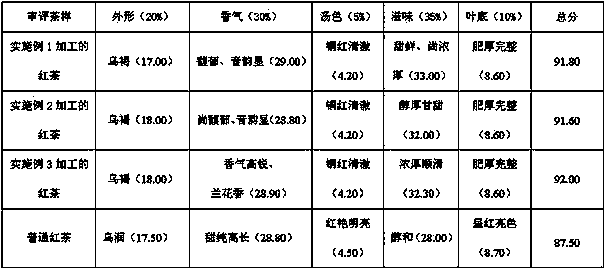

Examples

Embodiment 1

[0022] A kind of processing step of black tea is as follows:

[0023] 1) Cool green: spread the picked tea leaves on a sun-drying cloth or bamboo mat for 15 minutes, with a thickness of 10 cm;

[0024] 2) Sun-drying: spread the cooled tea leaves on a sun-drying cloth at 10:00 a.m. to dry in the sun, with a thickness of 2 cm. During this period, turn them over for 2 times, and sun-dry them for 10 minutes each time, until the leaves are soft and sticky. The color turns dark and loses luster, and the color of the back of the leaf is obviously "fish belly white";

[0025] 3) Re-cooling the greens: After drying the greens, follow step 1) to cool the greens to reduce the temperature of the leaves;

[0026] 4) Greening: Put the cool tea leaves into the green shaker at a speed of 60 r / min, and shake the green leaves for 1 min for the first time, until the green air is slightly exposed and the leaves are slightly tense; after shaking the green leaves Spread the tea leaves at 0.5 kg / s...

Embodiment 2

[0031] A kind of processing step of black tea is as follows:

[0032] 1) Cool green: spread the picked tea leaves on a sun-drying cloth or bamboo mat for 20 minutes, with a thickness of 12 cm;

[0033] 2) Green drying: Spread the cooled tea leaves on a bamboo mat at 9:00 am to dry in the sun, with a thickness of 3 cm. During this period, turn them in the sun for 3 times, and dry them for 10 minutes each time, until the leaves are soft and sticky, and the color turns. Dark, tarnished, leaf back color is obvious "fish belly white";

[0034] 3) Re-cooling the greens: After drying the greens, follow step 1) to cool the greens to reduce the temperature of the leaves;

[0035] 4) Greening: Put the cool tea leaves into the green shaker at a speed of 70 r / min, and shake the green leaves for 1 min for the first time, until the green air is slightly exposed and the leaves are slightly tense; after shaking the green leaves 0.6 kg / sieve of the tea leaves was spread over the entire water...

Embodiment 3

[0040] A kind of processing step of black tea is as follows:

[0041] 1) Cool green: spread the picked tea leaves on a sun-drying cloth or bamboo mat for 25 minutes, with a thickness of 15 cm;

[0042] 2) Sun-drying: Spread the cooled tea leaves on a bamboo mat at 2:20 p.m. to dry in the sun, with a thickness of 4 cm. During this period, turn them over for 15 minutes each time, until the leaves are soft and sticky , the color turns dark and loses luster, and the color of the back of the leaf is obviously "fish belly white";

[0043] 3) Re-cooling the greens: After drying the greens, follow step 1) to cool the greens to reduce the temperature of the leaves;

[0044]4) Greening: Put the cool tea leaves into the green shaking machine at a speed of 80 r / min, shake the green leaves for 1.5 min for the first time, with the green air slightly exposed and the leaves slightly tense; shake the green leaves 0.8 kg / sieve the whole water sieve to keep the leaves from overlapping each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com