Reverse micellar nano-alumina catalyst system and method for synthesizing modified epoxy plasticizer

A technology of nano-alumina and epoxy plasticizers, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. Due to limited application fields and complex processes, it achieves the effects of low freezing point, low migration and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

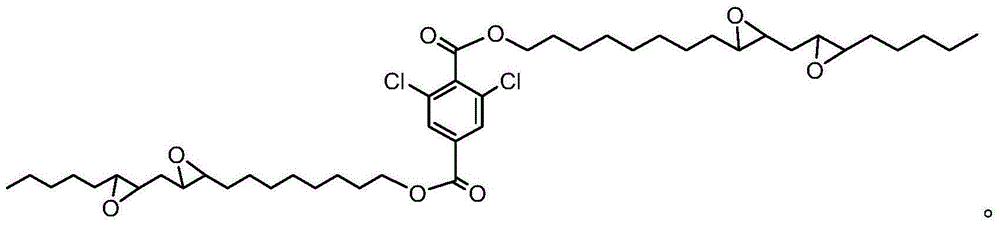

Image

Examples

Embodiment 1

[0042] Dissolve azobenzene in 100ml n-heptane / n-butanol mixed solvent, the volume ratio of the mixed solvent n-heptane / n-butanol is 10:1, and the concentration is 1×10 -6 mol / L solution, followed by ultrasonic oscillation for 30 min.

[0043] At room temperature, use a dropper to add the prepared sodium aluminate aqueous solution with a mass percentage concentration of 5% drop by drop until it is saturated and just not cloudy (about 9g). After the addition, continue ultrasonic oscillation for 30 minutes to accelerate The micelles are formed and the micellar structure is stabilized. Then, while carbon dioxide is passed into it, the ultrasonic reaction is continued for 1 hour at a reaction temperature of 50° C. to obtain the desired catalytic system—reverse micellar nano-alumina catalytic system.

[0044] Add concentrated sulfuric acid (the amount of concentrated sulfuric acid added is 16% of the weight of the soapstock) to the raw material oil soapstock, control the pH of the s...

Embodiment 2

[0053] Dissolve azobenzene in 100mL n-heptane / n-butanol mixed solvent, the molar ratio of mixed solvent n-heptane / n-butanol is 10:1, and the mass percentage concentration is 3×10 -5 mol / L solution, followed by ultrasonic oscillation for 30 min. At room temperature, use a dropper to add the prepared sodium aluminate aqueous solution with a concentration of 7% drop by drop until it is saturated and just not cloudy (about 6g). After the addition, continue ultrasonic oscillation for 45 minutes to accelerate the micelles. After forming and stabilizing the micelle structure, and then passing carbon dioxide into it, continue the ultrasonic reaction for 2 hours at a reaction temperature of 55°C to obtain the desired catalytic system—a reverse micelle nano-alumina catalytic system.

[0054] Add concentrated sulfuric acid (the amount of concentrated sulfuric acid added is 16% of the weight of the soapstock) to the raw material oil soapstock, control the pH of the solution within the ran...

Embodiment 3

[0063] Azobenzene is dissolved in 100ml n-heptane / n-butanol mixed solvent, the molar ratio of mixed solvent n-heptane / n-butanol is 10:1, and the mass percentage concentration is configured as 6×10 -3 mol / L solution, followed by ultrasonic oscillation for 30 min. At room temperature, use a dropper to add the prepared 10% sodium aluminate aqueous solution drop by drop until it is saturated and just not cloudy (about 6g). After the addition, continue ultrasonic oscillation for 60 minutes to accelerate the micelles. After forming and stabilizing the micelle structure, and then introducing carbon dioxide into it, the ultrasonic reaction was continued for 3 hours at a reaction temperature of 60°C to obtain the desired catalytic system—a reverse micelle nano-alumina catalytic system.

[0064] Add concentrated sulfuric acid (the amount of concentrated sulfuric acid added is 16% of the weight of the soapstock) to the raw material oil soapstock, control the pH of the solution within the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com