Equipment for fluid quantitative injection

A quantitative injection and equipment technology, applied in the manufacturing field, can solve the problems of large time error of pneumatic valves, high maintenance costs, and inaccurate injection volume of pneumatic fluid injection equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

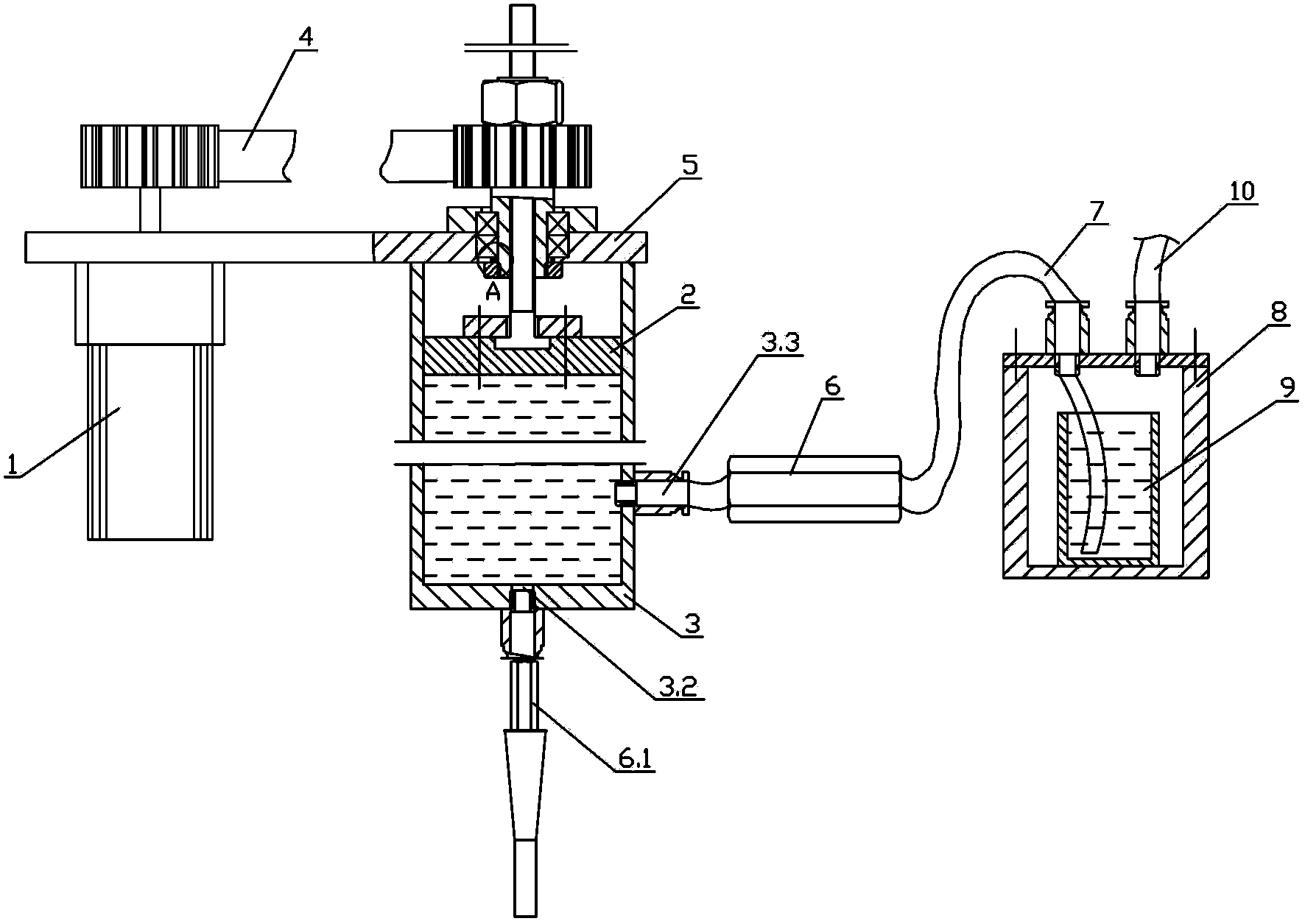

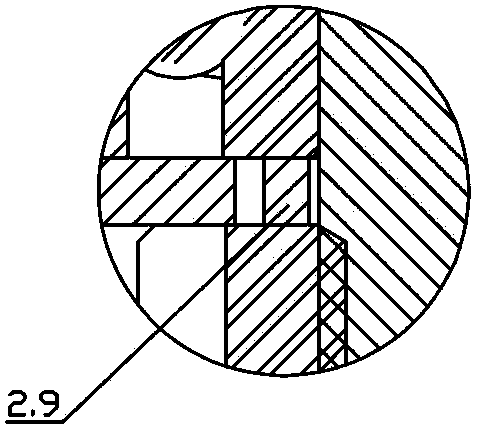

[0033] Such as Figure 1-4 , Image 6 As shown, in the fluid quantitative injection device of the present invention, the power mechanism 1 and the piston mechanism 2 are fixed on the base plate 5 , and the power mechanism 1 and the piston mechanism 2 are connected by a timing belt 4 .

[0034] The piston mechanism 2 in the power mechanism 1 is installed in the cylinder body 3; the cylinder body 3 is fixed on the base plate 5, the second one-way valve 6.1 is fixed on the discharge port 3.2, and one end of the delivery pipe 7 passes through the first one-way valve 6 is connected with the cylinder body 3, the other end of the delivery pipe 7 is inserted into the bottom of the barrel 9 through the pressure cylinder 8, and one end of the compressed air pipe 10 is connected with the pressure cylinder 8.

[0035] The power mechanism 1 can adopt the following two technical solutions.

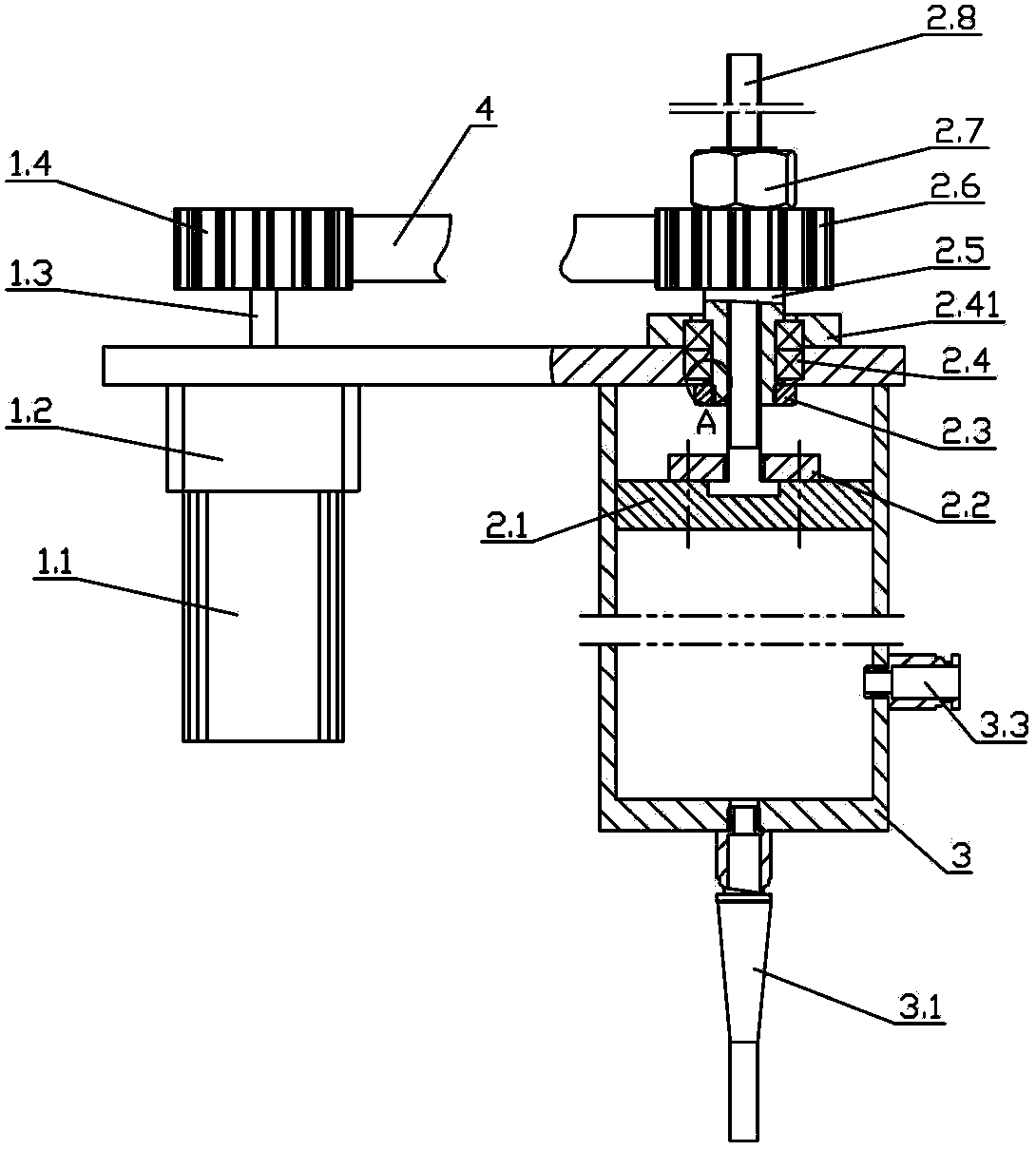

[0036] Such as figure 2 As shown, the power mechanism 1 includes a motor 1.1, a reducer 1.2 and ...

Embodiment 2

[0044] The main difference between the second embodiment and the first embodiment lies in the structure of the power mechanism and the connection relationship with the piston mechanism.

[0045] Such as Figure 5 as shown, Figure 5 It is a schematic diagram of the connection between another power mechanism and the piston mechanism in the fluid quantitative injection device of the present invention. The power mechanism 1 includes a motor 1.1, a reducer 1.2 and a motor output shaft 1.3, and the motor 1.1 is connected with the reducer 1.2. The transmission nut 2.5 in the piston mechanism 2 is arranged inside the speed reducer 1.2, and cooperates with the screw rod 2.8, and the screw rod 2.8 is connected with the piston 2.1 through the first end cover 2.2.

[0046] Combine below figure 1 , Figure 5 Describe the working principle of the fluid quantitative injection device of the present invention.

[0047]When the motor 1.1 in the power mechanism 1 rotates forward, the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com