Environmentally friendly pu foaming method

An environmentally friendly, hydroxyl-based technology, applied in the field of foaming, can solve problems such as atmospheric damage, avoid hydrolysis reactions, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

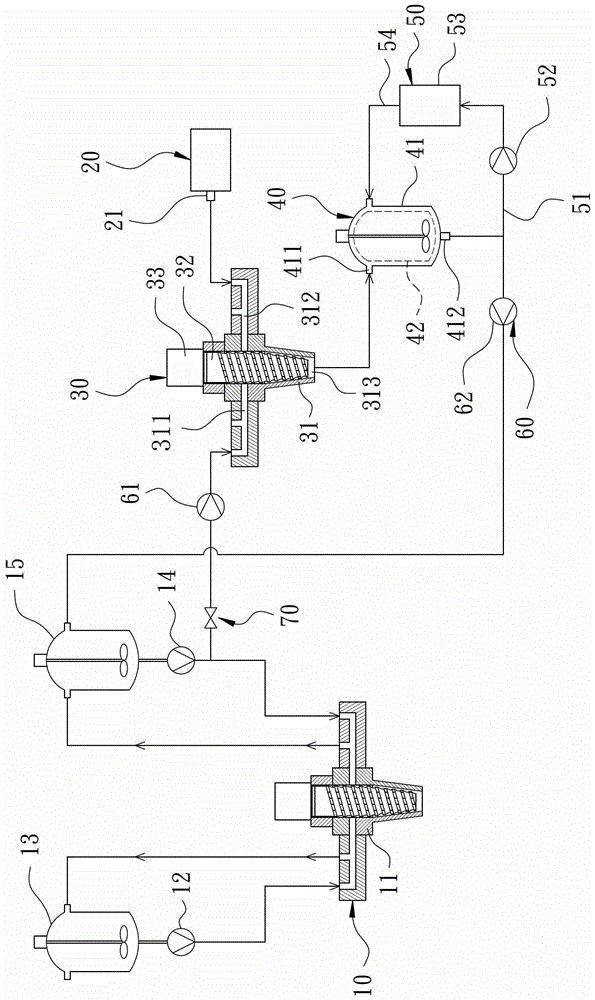

[0031] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention, which are only provided for reference and description, and are not intended to limit the present invention.

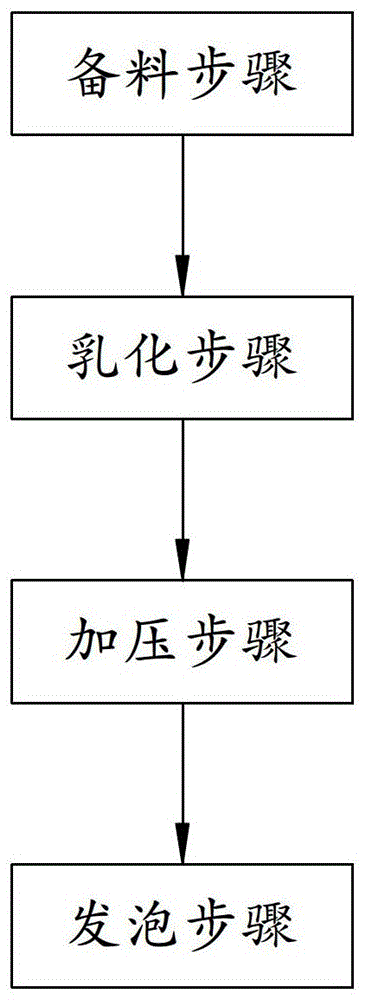

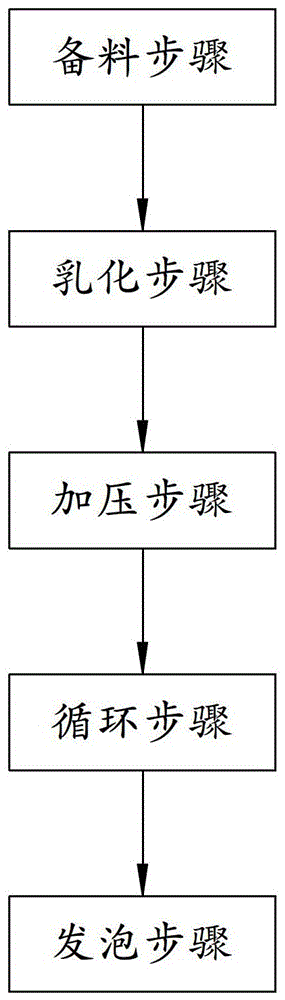

[0032] see figure 1 as well as figure 2 As shown, it is a schematic block diagram and a schematic diagram of equipment connection of the first preferred embodiment of the present invention, which discloses an environmentally friendly PU foaming method, and the environmentally friendly PU foaming method includes the following steps:

[0033] Material preparation step: prepare a hydroxyl compound containing OH (hydroxyl group), an isocyanate polymer containing NCO (isocyanate group) and a harmless gas, wherein, the material preparation step is performed by a foam filling machine 10, the The foam filling machine 10 has a filling machine body 11, and the filling machine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com