Surface alloying method of powder-like ceramic material

A technology for surface alloying and ceramic materials, applied in the field of surface alloying of powder ceramic materials, can solve the problems of difficulty in process parameters, difficulty in distance speed between composite target and powder, etc., achieve advanced and reasonable preparation technology, improve interface plasticity, guarantee The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

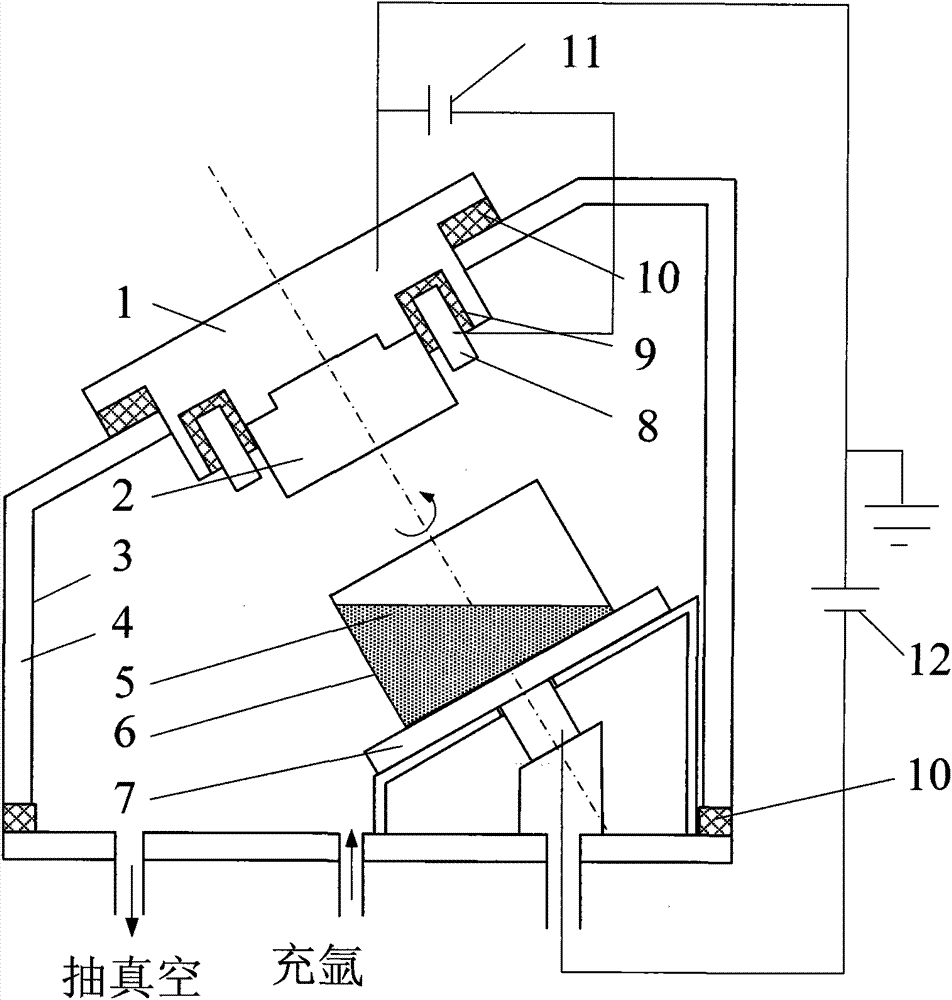

[0032] figure 1 Shown is an arc-added glow ion plating device, which is composed of a closed furnace wall with a jacket. There is circulating water in the jacket of the furnace wall, and the bottom of the furnace wall is respectively equipped with a vacuum port and an argon gas port. .

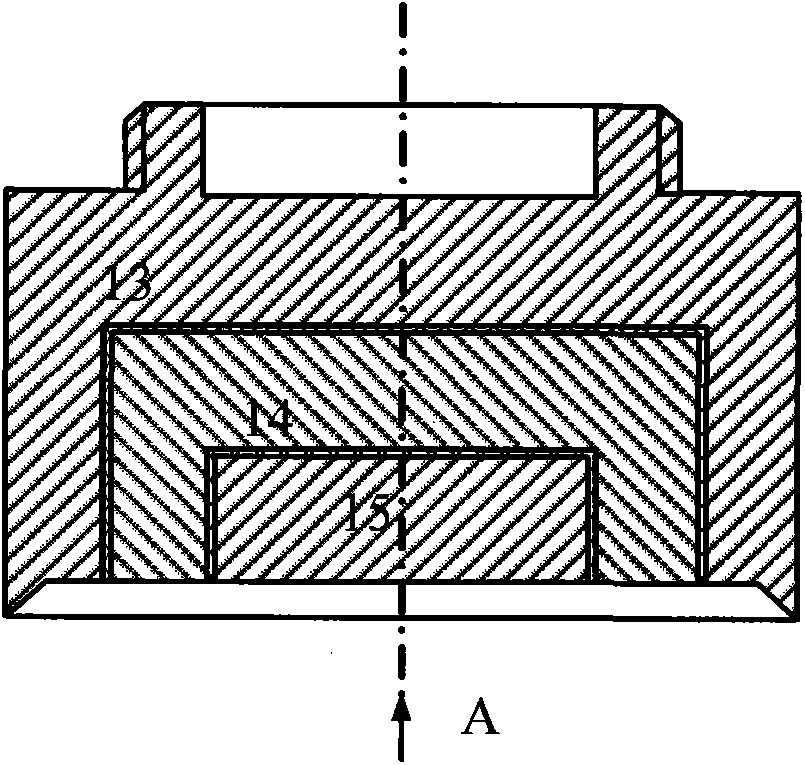

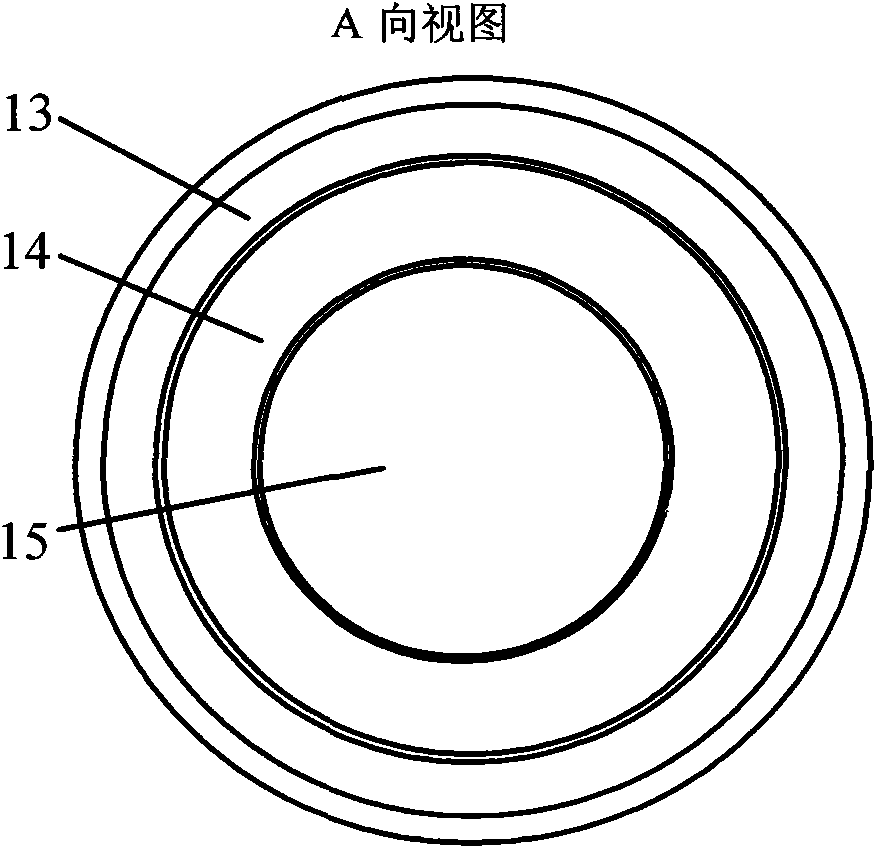

[0033] The cathode seat is installed at the bottom of the furnace wall, and is inclined to rotate along the axis of the cathode seat. Fixed on the cathode holder is a Figure 4 , Figure 5 The shown cylinder is made of 304 austenitic stainless steel, and the specification of the cylinder is Φ300mm×30mm×1mm, such as Image 6 As shown, six stainless steel strips parallel to each other are obliquely arranged on the inner wall of the barrel. Ceramic powder is placed in the barrel, B in the embodiment 4 C ceramic powder.

[0034] The anode target seat is fixed on the furnace wall on the opposite side of the cathode seat, and is arranged coaxially with the cathode seat. A composite target per...

Embodiment 2

[0047] The B described in material embodiment 1 4 C ceramic powder is replaced by ZrO 2 Ceramic powder, other conditions remain the same, after the preparation is completed, the product is observed under a microscope, the microstructure of the ceramic interface after ion glow plating, the ion has been uniformly plated on the ZrO during the process of plating 2 Surface of ceramic material.

Embodiment 3

[0049] The B described in material embodiment 1 4 Replacement of C ceramic powder with Si 3 N 4 Ceramic powder, other conditions remain the same, after the preparation is completed, the product is observed under a microscope, the microstructure of the ceramic interface after ion glow plating, the ion has been uniformly plated on Si during the process of plating 3 N 4 Surface of ceramic material.

[0050] The invention relates to a method for surface alloying of powdery ceramic materials, which is aimed at the preparation of powdery ceramic composite materials, and adopts a composite target with an inlaid structure machined from aluminum rods, copper rods and titanium rods as a permeation source, ceramic powder powder As the raw material, the method of arc-glow composite ion plating is used to make aluminum-copper-titanium alloy ceramic powder materials in a vacuum state, and the container is rotated while plating to ensure the uniformity of plating. This preparation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com