Repairing method for cracks on roll surface of rolling mill back-up rolls

A repair method and technology of supporting rollers, which are applied in the field of mechanical equipment surface repair, can solve the problems of secondary cracking and poor repair effect, and achieve the effects of small amount of grinding, increased cladding quality, and improved uneven distribution of high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

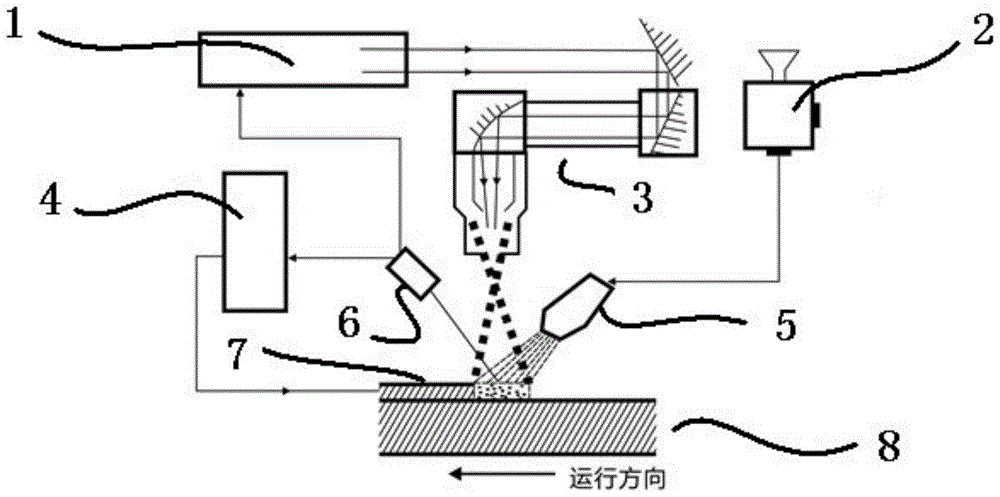

[0034] A kind of repair method of rolling mill back-up roll roll surface crack (referring to figure 1 shown), including:

[0035] (a) Crack pretreatment

[0036] Clear the crack defect area on the roll surface;

[0037] Use magnetic particle flaw detection, X-ray flaw detection, fluorescent flaw detection or display flaw detection method to detect the crack defect. Confirm whether there is a tendency of hydrogen embrittlement, cracking or internal cracking.

[0038] (b) Repair

[0039] Use nickel-based alloy powder to clad the parts to be repaired by laser, equipment: 3000W high-power all-solid-state laser. When cladding, pay attention to the cladding layer is uniform, continuous, free of metallurgical defects such as cracks and pores.

[0040] Vibration aging treatment, equipment: automatic vibration aging device. The exciter causes resonance, and uses low-frequency vibration of 200Hz to excite molecular activities, displace the grain boundaries in the metal, and releas...

Embodiment 2

[0050] A method for repairing cracks on the roll surface of a back-up roll of a rolling mill, comprising:

[0051] (a) Crack pretreatment

[0052] Clear the crack defect area on the roll surface;

[0053] Use magnetic particle flaw detection, X-ray flaw detection, fluorescent flaw detection or display flaw detection method to detect the crack defect. Confirm whether there is a tendency of hydrogen embrittlement, cracking or internal cracking.

[0054] (b) Repair

[0055] Use nickel-based alloy powder to clad the parts to be repaired by laser, equipment: 3000W high-power all-solid-state laser. When cladding, pay attention to the cladding layer is uniform, continuous, free of metallurgical defects such as cracks and pores.

[0056] Vibration aging treatment, equipment: automatic vibration aging device. The exciter causes resonance, and uses low-frequency vibration of 200Hz to excite molecular activities, displace the grain boundaries in the metal, and release the stress ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com