Reusable substrate for additive manufacturing and reusing method

A technology of additive manufacturing and substrates, which is applied in the field of additive manufacturing and reused substrates, can solve problems such as too thin thickness and large deformation, and achieve the effects of easy adjustment, reduced processing area, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

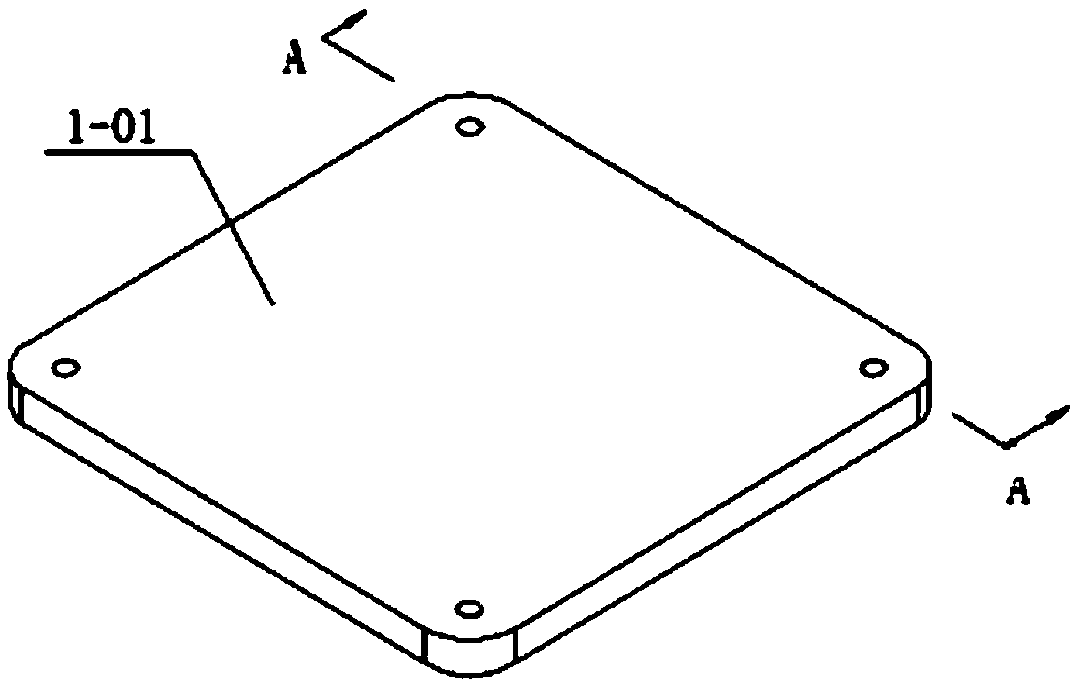

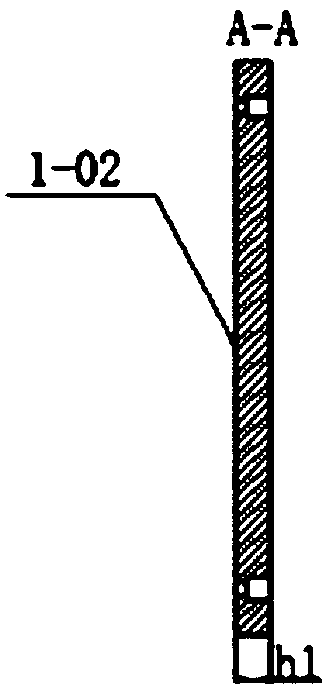

[0041] A reusable substrate for additive manufacturing, comprising a powdered surface of the substrate and a bonding surface of a workbench parallel to each other, the bonding surface of the worktable is provided with three bosses, and counterbores are arranged on the bosses.

[0042] The thickness of the substrate is increased by 50% to 100%, and the thickness of this embodiment is increased by 100%.

Embodiment 2

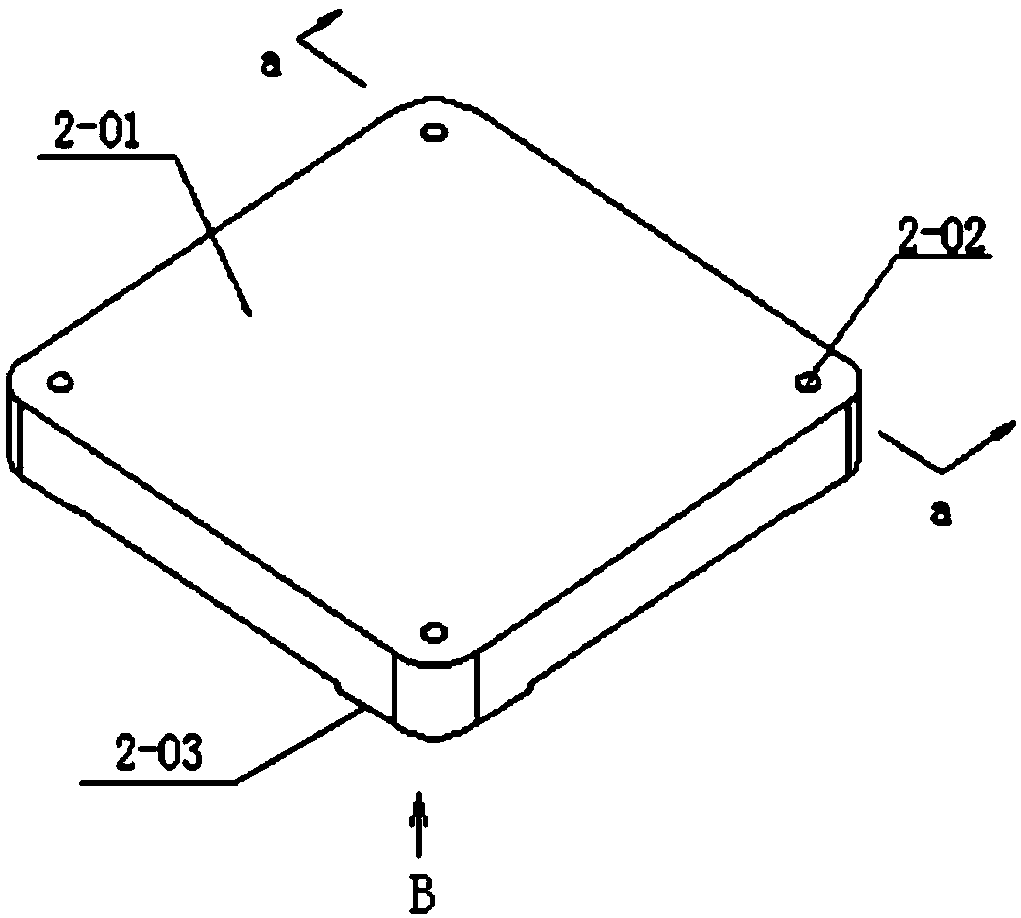

[0044] Refer to attached Figure 2-5 , a reusable substrate for additive manufacturing. Compared with Embodiment 1, the difference is that there are four bosses, which are respectively arranged at four right angles of the bonding surface of the workbench; the thickness of the substrate 80% increase. The rest of the content is the same as in Embodiment 1. Another embodiment has a 60% increase in the thickness of the substrate.

Embodiment 3

[0046] A reusable substrate for additive manufacturing. Compared with Embodiment 1, the difference is that there are five bosses, which are respectively arranged at four right angles and the center of the bonding surface of the workbench; the substrate The thickness is increased by 50%. The rest of the content is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com