Energy-saving air-jet loom

An air-jet loom, energy-saving technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of large air consumption, large capital investment, pipeline loss and waste, etc., to increase stability and reliability, reduce Weaving cost, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

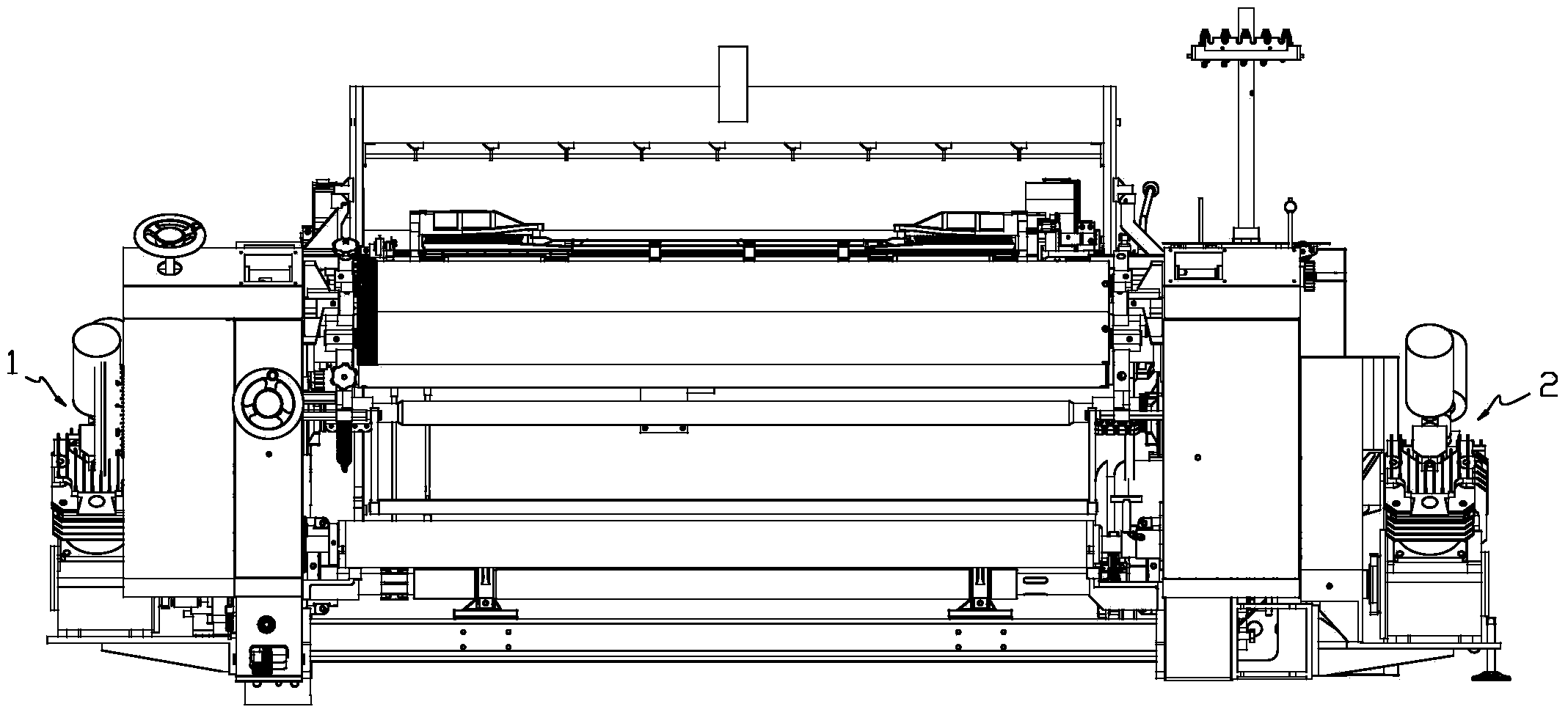

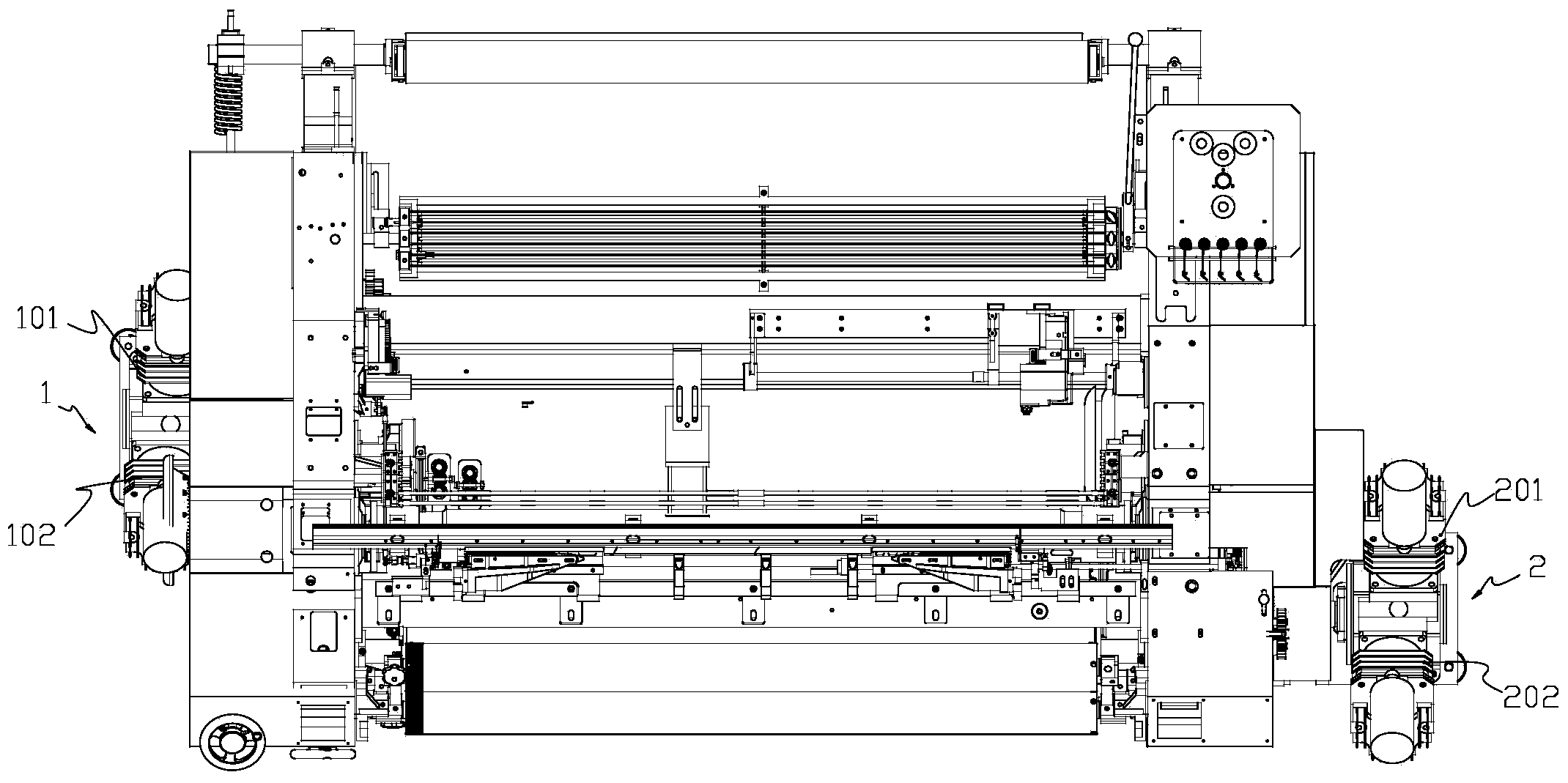

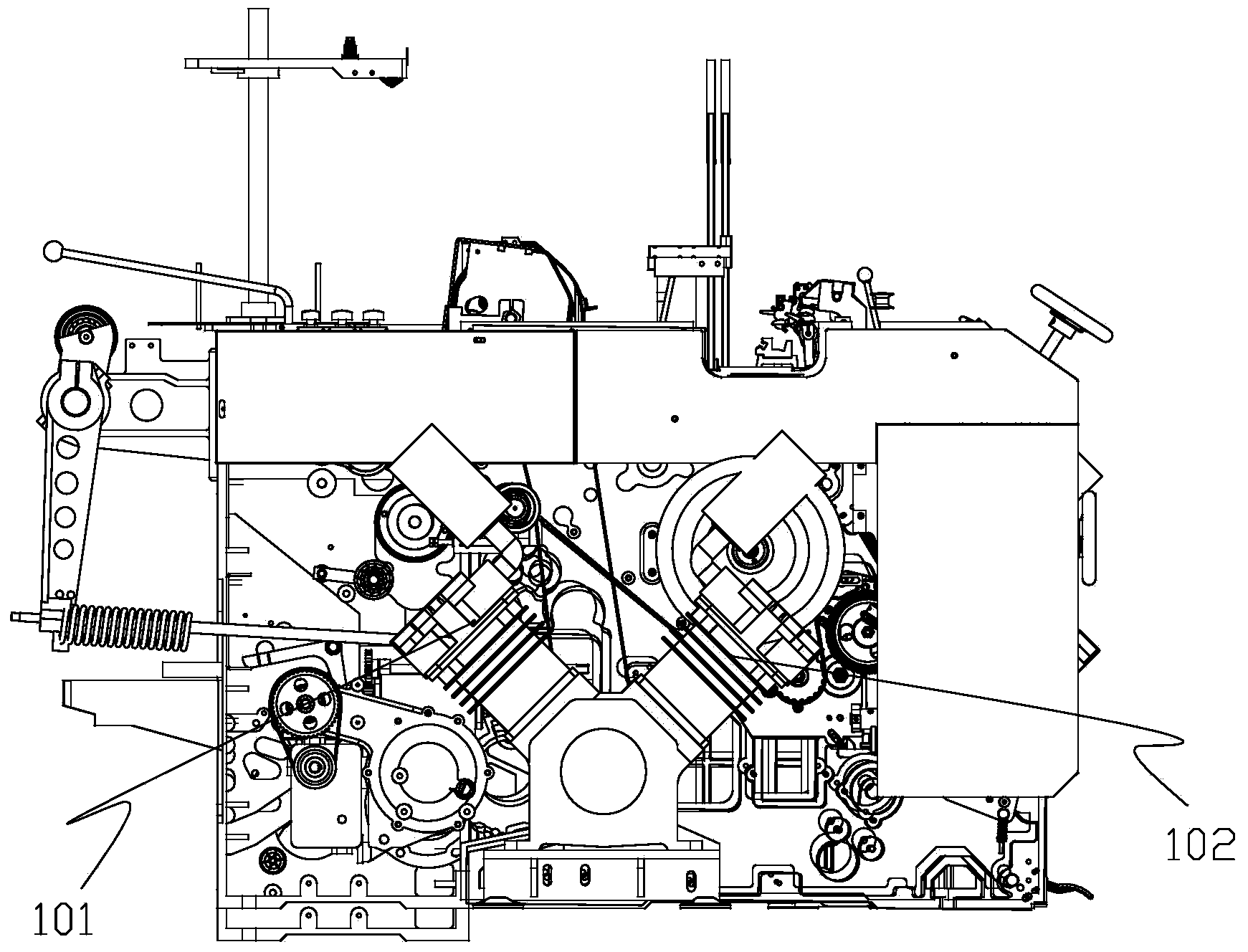

[0028] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6, an energy-saving air-jet loom, comprising a frame and an air-jet weft insertion mechanism. The air jet weft insertion mechanism includes a first air pump 1 , a second air pump 2 , a main nozzle group 3 and an auxiliary nozzle group 4 . The above-mentioned main nozzle group has at least one main nozzle 301, and the auxiliary nozzle group has several auxiliary nozzles 401 arranged in sequence on the weft flight path. The first air pump is arranged on one side of the frame, and it includes a main plunger cylinder 101 and an auxiliary plunger cylinder 102. The two plunger cylinders are connected as one, and the piston rods of the two plunger cylinders are connected to the On the crankshaft, the crankshaft is connected to the power spindle of the loom, that is, the power spindle of the loom drives the main plunger cylinder and the auxiliary plunger cylinder to run through the crankshaft; of ...

Embodiment 2

[0034] to combine Figure 7 , except for the following content, other technical content may be the same as the corresponding part of Embodiment 1.

[0035] An energy-saving air jet loom comprises a frame and an air jet weft insertion mechanism, including a frame and an air jet weft insertion mechanism. The air jet weft insertion mechanism includes a first air pump, a second air pump, a main nozzle group and an auxiliary nozzle group. The above-mentioned main nozzle group has at least one main nozzle, and the auxiliary nozzle group has several auxiliary nozzles arranged in sequence on the weft flight path. The first air pump is set on the side wall of the frame, which includes a main plunger cylinder and an auxiliary plunger cylinder. The two plunger cylinders are connected as a whole, and the piston rods of the two plunger cylinders are connected to the same crankshaft. , the crankshaft is connected to the power spindle of the loom, that is, the power spindle of the loom dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com