Joint of cable support pentagonal and hexagonal grid single-layer reticulated shell and installation and construction method for single-layer reticulated shell

A technology of hexagonal grid and single-layer reticulated shell, which is applied in the direction of arch structure, dome structure, building material processing, etc., can solve the problem of polygonal grid stability and poor in-plane stiffness, without large-scale 5. Project examples of hexagonal grid single-layer reticulated shells, few applications of single-layer reticulated shells, etc., to achieve reasonable force, simple structure, and reliable structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

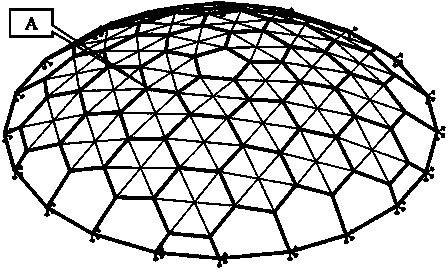

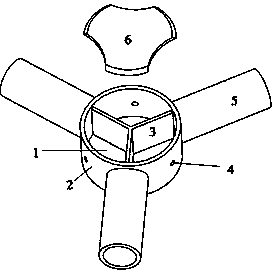

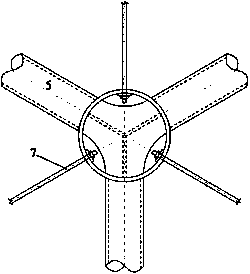

[0013] figure 1 It is a schematic diagram of a cable-supported single-layer reticulated shell with pentagonal and hexagonal grids. The structure of a typical node A in the figure is as follows figure 2 with image 3 As shown, the node includes a bottom plate 1, a cover plate 6, a central circular tube 2, and an internal trident stiffener 3. The bottom plate 1 is circular in shape and is welded to the central circular tube 2 through a full-penetration butt weld in the factory. The inner trident stiffener 3 is used as a node reinforcement part, which is only used when necessary. In the factory, it is welded with the middle circular tube 2 and the bottom plate 1 through a full penetration butt weld or fillet weld. The upper part of the trident stiffener 3 is larger than the middle part. The top of the round pipe 2 is low, and its height difference is the thickness of the cover plate 6 . The cover plate 6 is cut from a circular plate with a diameter equal to the inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com