A proportional flow rotary valve for AC servo motor direct drive type unloading

An AC servo motor and servo motor technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of immature multi-stage cartridge valve technology, increase equipment costs, and high maintenance costs, and achieve simple structure and processing. The effect of convenient and fast oil discharge control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

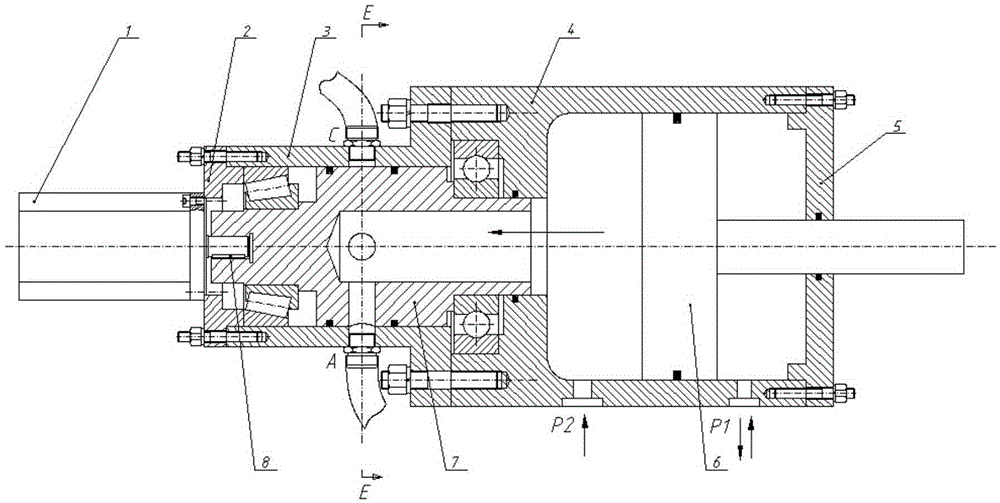

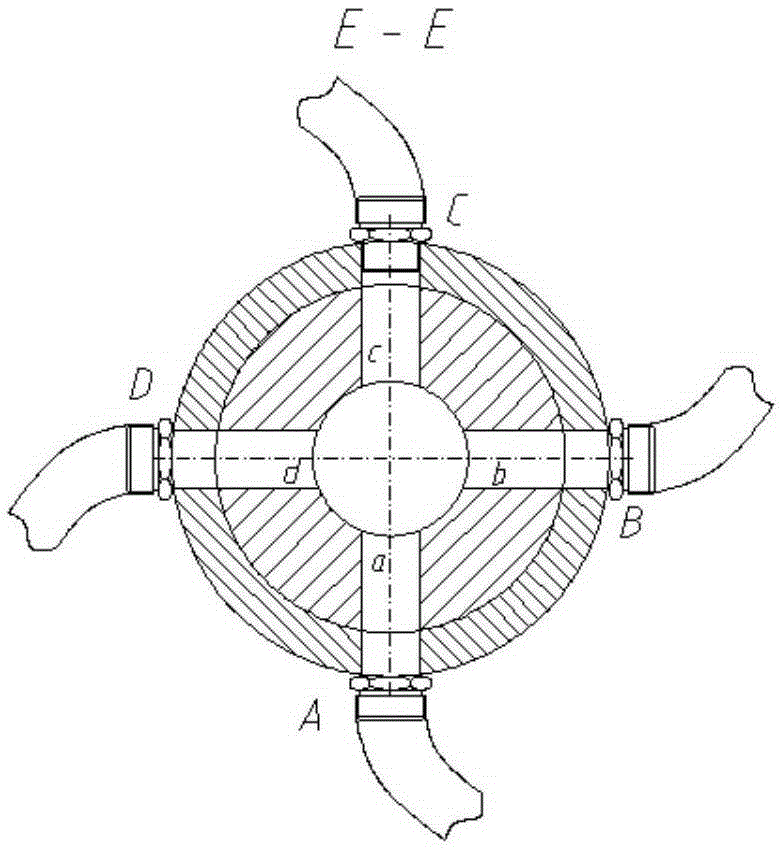

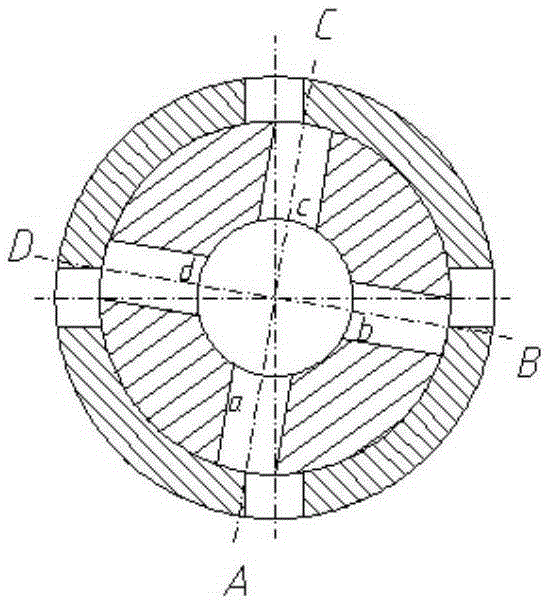

[0016] Such as figure 1 , figure 2 with Figure 5 As shown, an AC servo motor direct-drive proportional flow rotary valve for unloading, including a servo motor 1, the servo motor 1 is connected with the flange 2 of the rotary valve through a double-headed stud, and the output shaft of the servo motor 1 Connect the spool 7 of the rotary valve through the key 8. The rotary valve includes a flange 2, a spool 7 and a valve sleeve 3. The valve sleeve 3 is connected to the flange 2 through a double-ended stud. The radial circumference of the valve sleeve 3 is uniform. There are four first through holes A, second through holes B, third through holes C, and fourth through holes D with the same diameter, the first through hole A, the second through hole B, the third through hole C, the fourth through hole The four through holes D are connected to the fuel tank th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com