Method for detecting and monitoring cracks of mechanical parts by utilizing fluorescent quantum dots

A technology of fluorescent quantum dots and mechanical components, which is applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve problems such as inability to use real-time security monitoring, and achieve high engineering application value, high detection accuracy, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

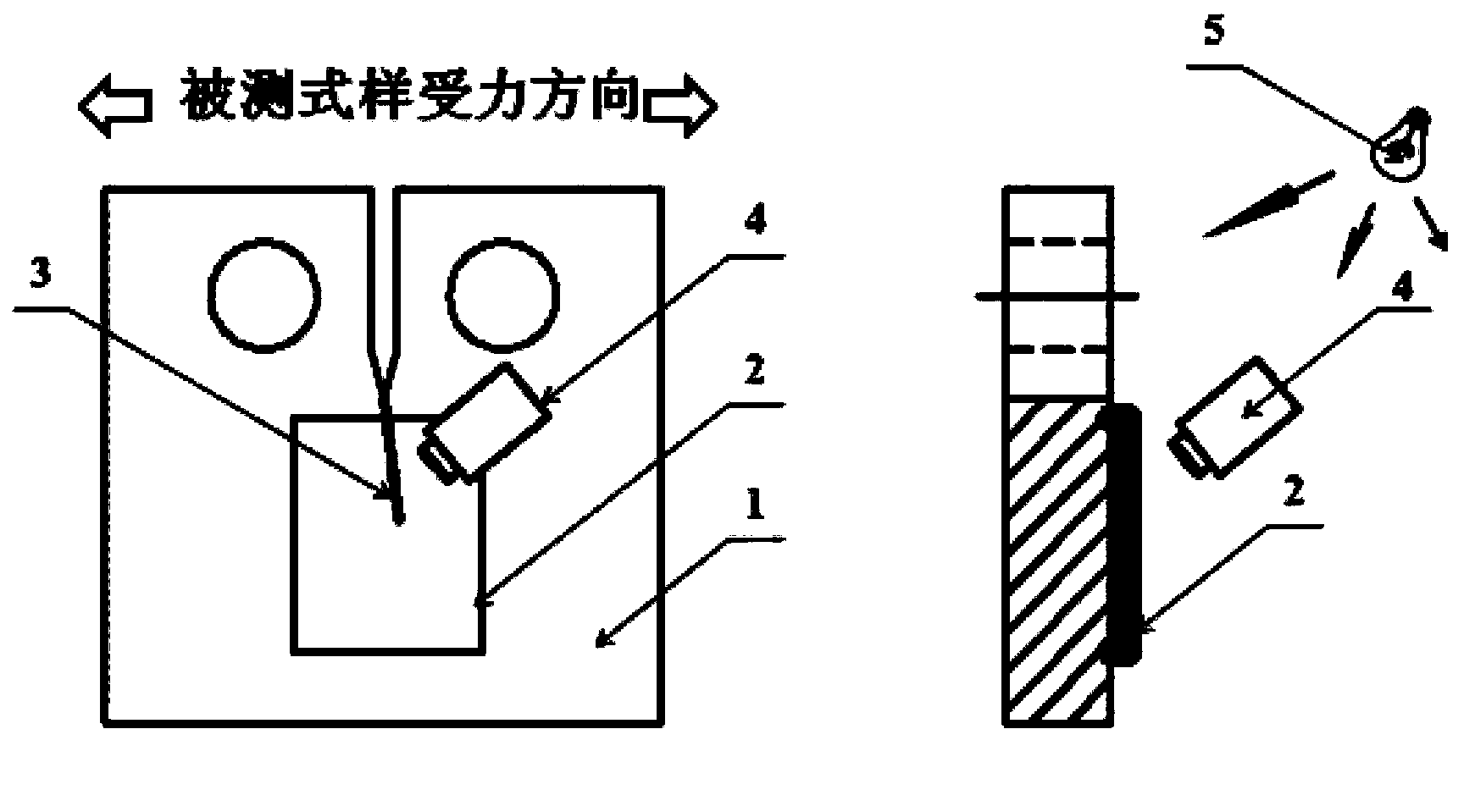

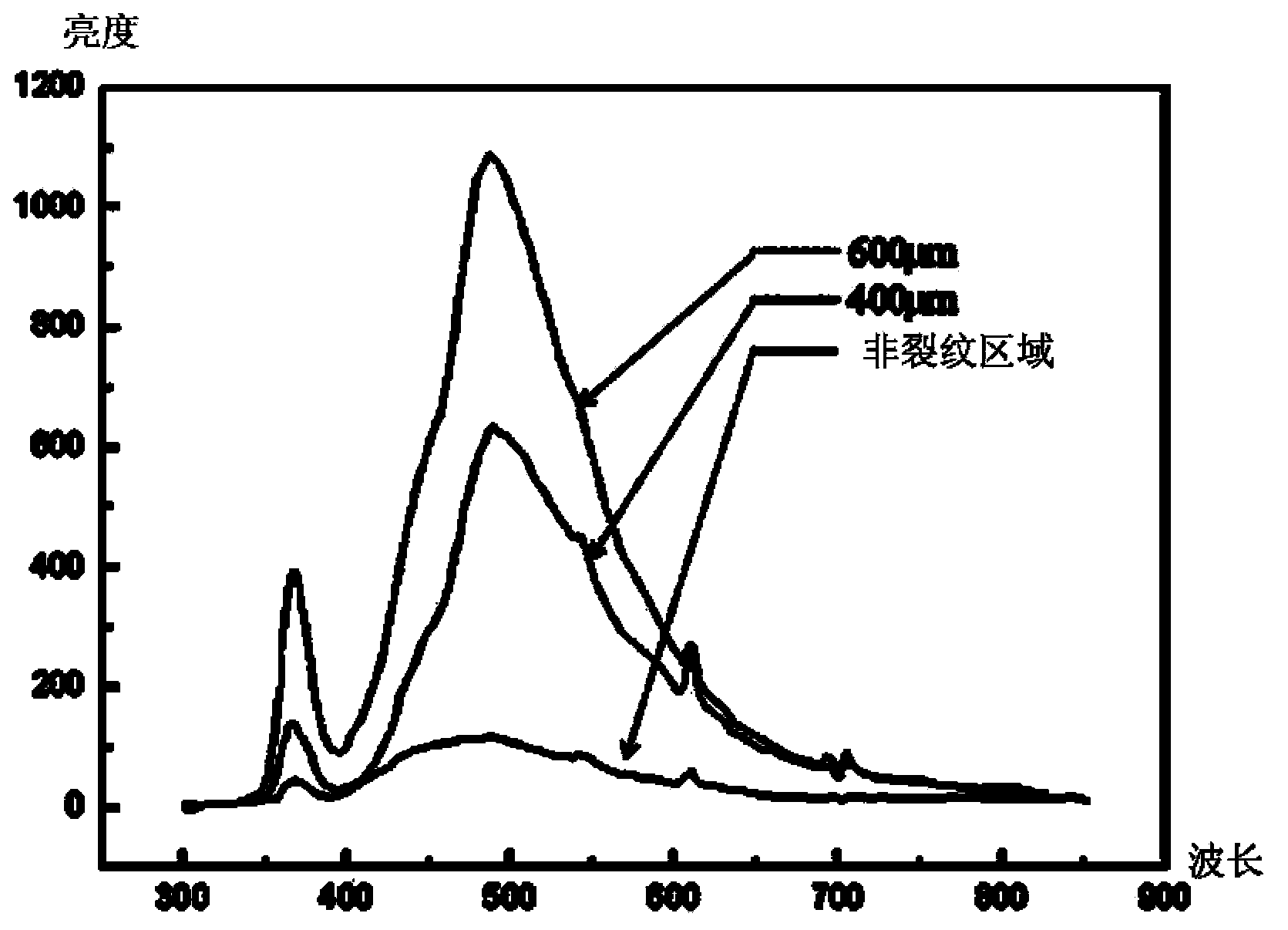

[0035] In order to better understand the above technical solutions of the present invention, the following further describes in detail with reference to the accompanying drawings and embodiments.

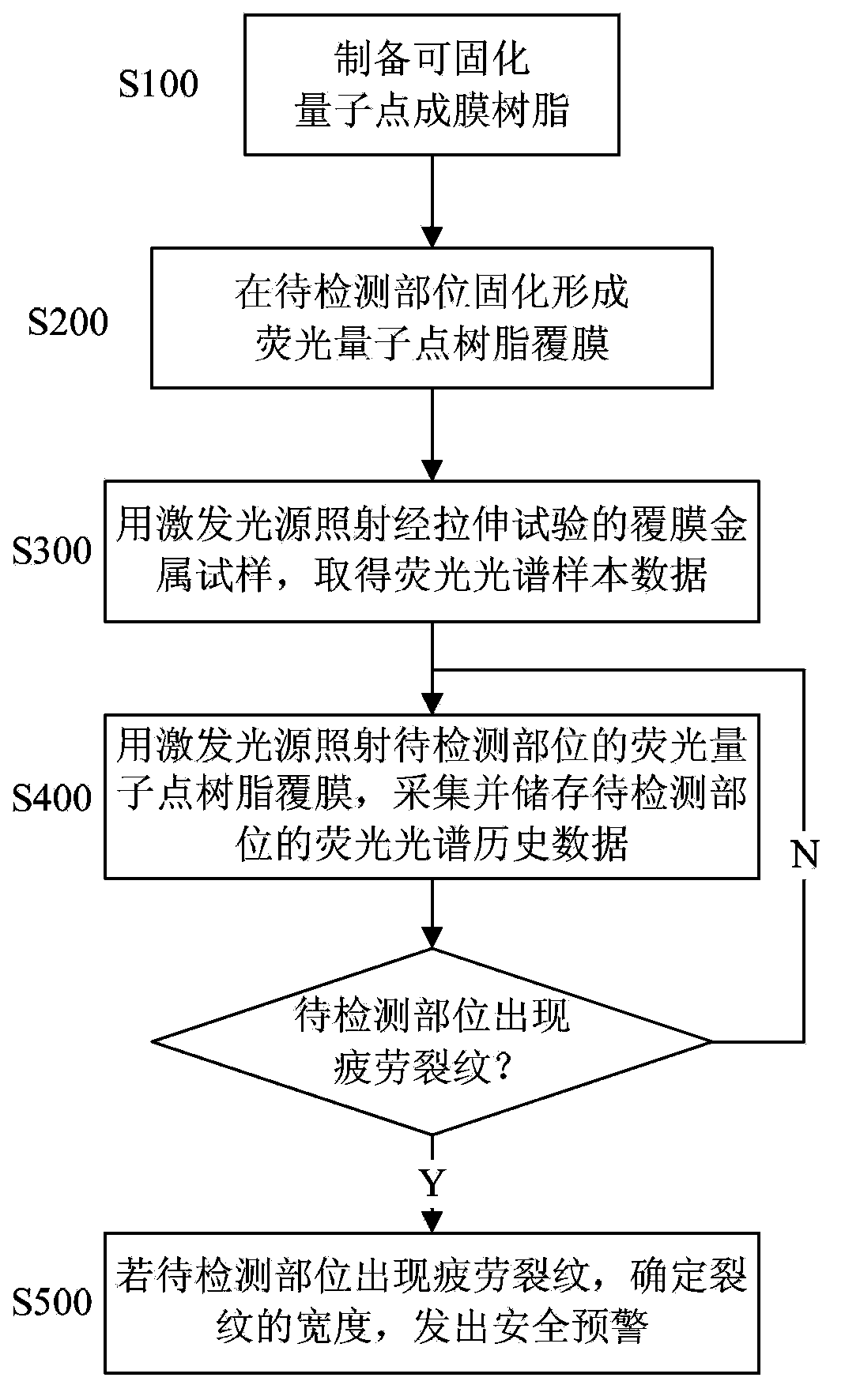

[0036] An embodiment of the method for detecting and monitoring cracks in mechanical parts using fluorescent quantum dots in the present invention figure 1 As shown, including the following steps:

[0037] S100) Select fluorescent quantum dot materials and curable film-forming resin materials to prepare curable quantum dot film-forming resin;

[0038] Semiconductor fluorescent quantum dots, abbreviated as quantum dots (QDS), means that the size of the material is constrained in three-dimensional space and reaches a certain critical size (can be abstracted as a dot), so it exhibits many unique optical and electrical properties. Especially the fluorescent quantum dots composed of II-VI or III-V elements, such as CdSe, CdTe, CdS, etc., are currently commonly used fluorescent quantum dot mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com