Steam-driven draught fan full working condition online monitoring model modeling method based on CPSO-LSSVM

A model modeling, induced draft fan technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of no steam induced induced draft fan, increased complexity of variable speed adjustment, etc., to avoid poor accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

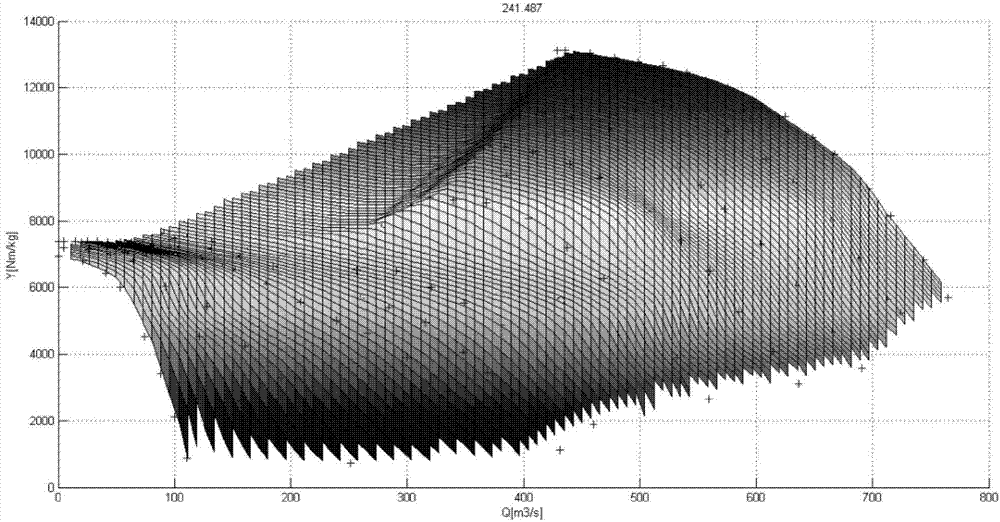

[0021] Taking the online monitoring model of a steam-driven induced draft fan of a 660MW unit in a power station as an example, the operating characteristic data of the steam-driven induced draft fan provided by the fan manufacturer are obtained, including data at various openings of 995r / min and data at some other speeds. Modeling mainly includes core modules such as data processing, least squares support vector machine training modeling, retraining model, publishing model and correcting model.

[0022] (1) Data processing: Screen and analyze the 995r / min characteristic data provided by the design manufacturer to select 538 data, and determine the following parameters of the data, specific pressure Y (p / ρ, where p is the total pressure of the fluid, and ρ is the fluid density) , volume flow Q, blade angle β and fan speed n, 152 of them are selected as training data, and all 538 of them are used as test data.

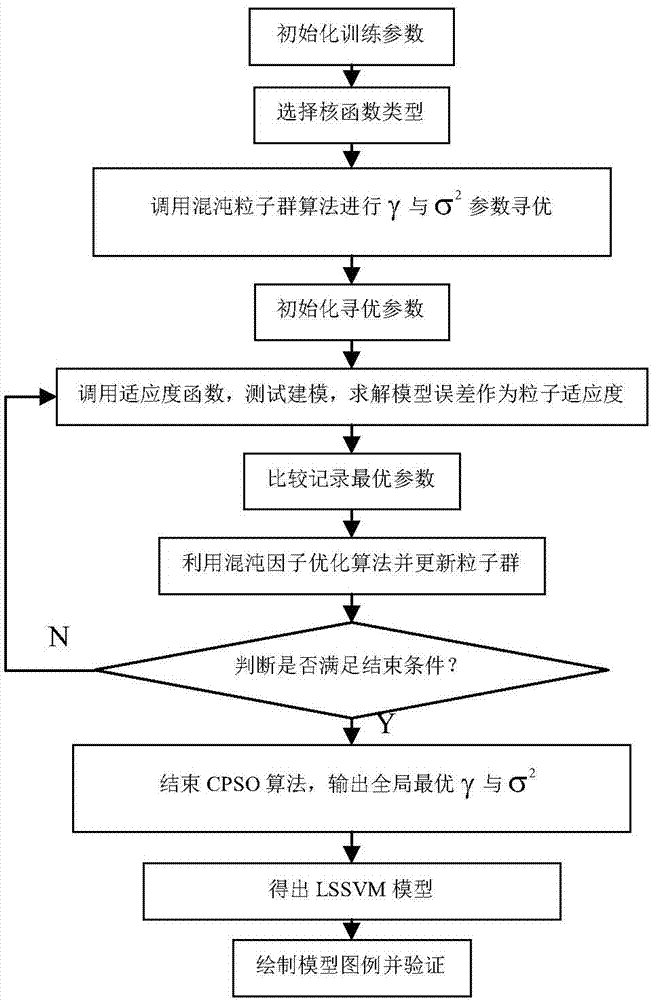

[0023] (2) Least squares support vector machine training modeling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com