A method for preparing corrosion-resistant NdFeB permanent magnets

A NdFeB, corrosion-resistant technology, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of corrosion resistance decline, loose combination, etc., and achieve the effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

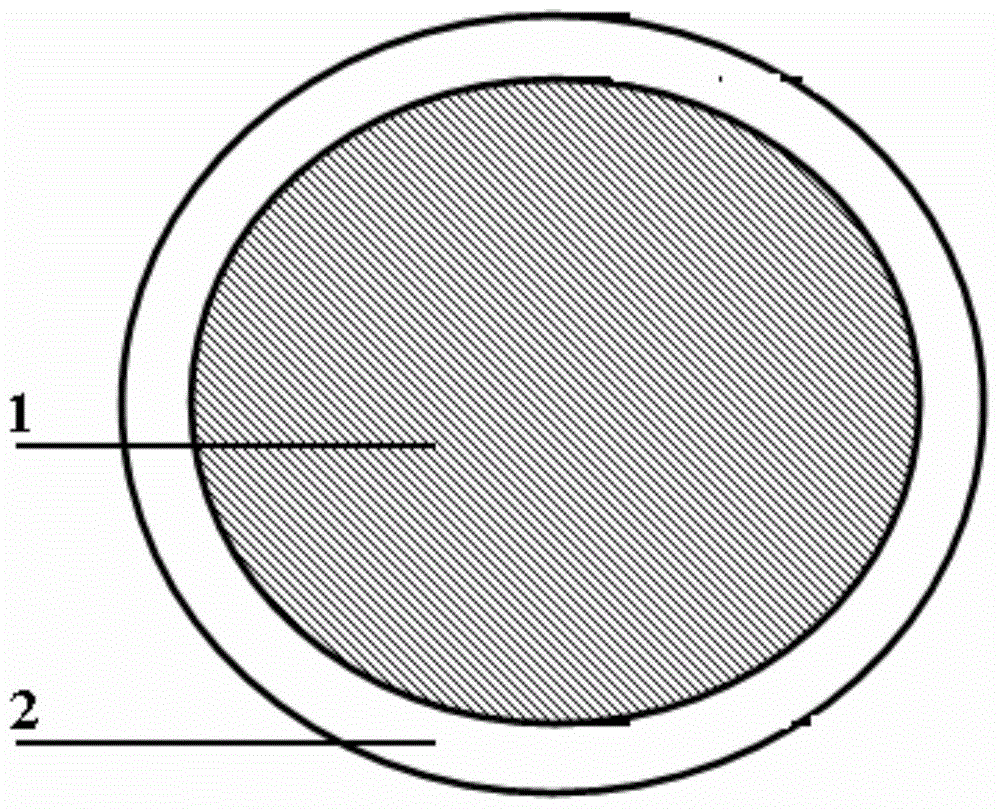

Image

Examples

Embodiment 1

[0024] (1) Take 10g of NdFeB powder with a particle size of 50μm, wash it with distilled water, and put it into the mixture with a component concentration of 9g L -1 NaOH, 45g·L -1 Na 2 CO 3 , 65g·L -1 Na 3 PO 4 and 1.5g·L -1 In the degreasing liquid composed of OP-10, degreasing under the action of 40kHZ, 100W ultrasonic. Ensure that the temperature during degreasing is 65°C, the degreasing time is 4min, and the pH value of the solution is 9.

[0025] (2) Filter the degreased powder, wash it with distilled water and place it in 3% HCl and 1g L -1 Pickling in the pickling solution composed of thiourea. Control pickling temperature is 20 ℃. Pickling time is 20s.

[0026] (3) Filter the powder after pickling, wash it with distilled water, and place the concentration of each component at 10g·L -1 of citric acid and 12g·L -1 Activated in the activation solution of ammonium bifluoride. The activation temperature is 20°C. The activation time is 20s.

[0027] (4) After...

Embodiment 2

[0035] (1) Take 10g of NdFeB powder with a particle size of 10μm, wash it with distilled water, and put it into the mixture with a component concentration of 8g L -1 NaOH, 40g·L -1 Na 2 CO 3 , 62g·L -1 Na 3 PO 4 and 1g·L -1 In the degreasing liquid composed of OP-10, degreasing under the action of 40kHZ, 100W ultrasonic. Ensure that the temperature during degreasing is 80°C, the degreasing time is 1min, and the pH value of the solution is 11.

[0036] (2) Filter the degreased powder, wash it with distilled water and place it in 1% HCl and 1g L -1 Pickling in the pickling solution composed of thiourea. Control the pickling temperature to 10°C. Pickling time is 60s.

[0037] (3) Filter the powder after pickling, wash it with distilled water, and place the concentration of each component at 5g·L -1 of citric acid and 10g·L -1 Activated in the activation solution of ammonium bifluoride. The activation temperature is 15°C. The activation time is 60s.

[0038] (4) After...

Embodiment 3

[0046] (1) Take 10g of NdFeB powder with a particle size of 120 μm, wash it with distilled water and put it into NaOH with a component concentration of 10g L-1, Na2CO3 with 60g L-1, Na3PO4 with 80g L-1 and In the degreasing liquid composed of 2g·L-1 OP-10, degreasing under the action of 40kHZ, 100W ultrasonic. Ensure that the temperature during degreasing is 40°C, the degreasing time is 5min, and the pH value of the solution is 8.

[0047] (2) Filter the degreased powder, wash it with distilled water, and pickle it in a pickling solution composed of 5% HCl and 1g·L-1 thiourea. Control pickling temperature is 40 ℃. Pickling time is 10s.

[0048] (3) Filter the pickled powder, wash it with distilled water, and activate it in an activation solution of citric acid with a concentration of 30 g·L-1 and ammonium bifluoride with a concentration of 14 g·L-1. The activation temperature is 40°C. The activation time is 10s.

[0049] (4) After cleaning the activated powder, add a comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap