Organic light emitting device with barrier layer

An electroluminescent device and barrier layer technology, which is applied in the direction of electro-solid devices, electrical components, semiconductor devices, etc., can solve the problems of low luminous efficiency, triplet energy level mismatch, etc., to ensure luminous efficiency, excellent luminous efficiency, Easy to choose effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

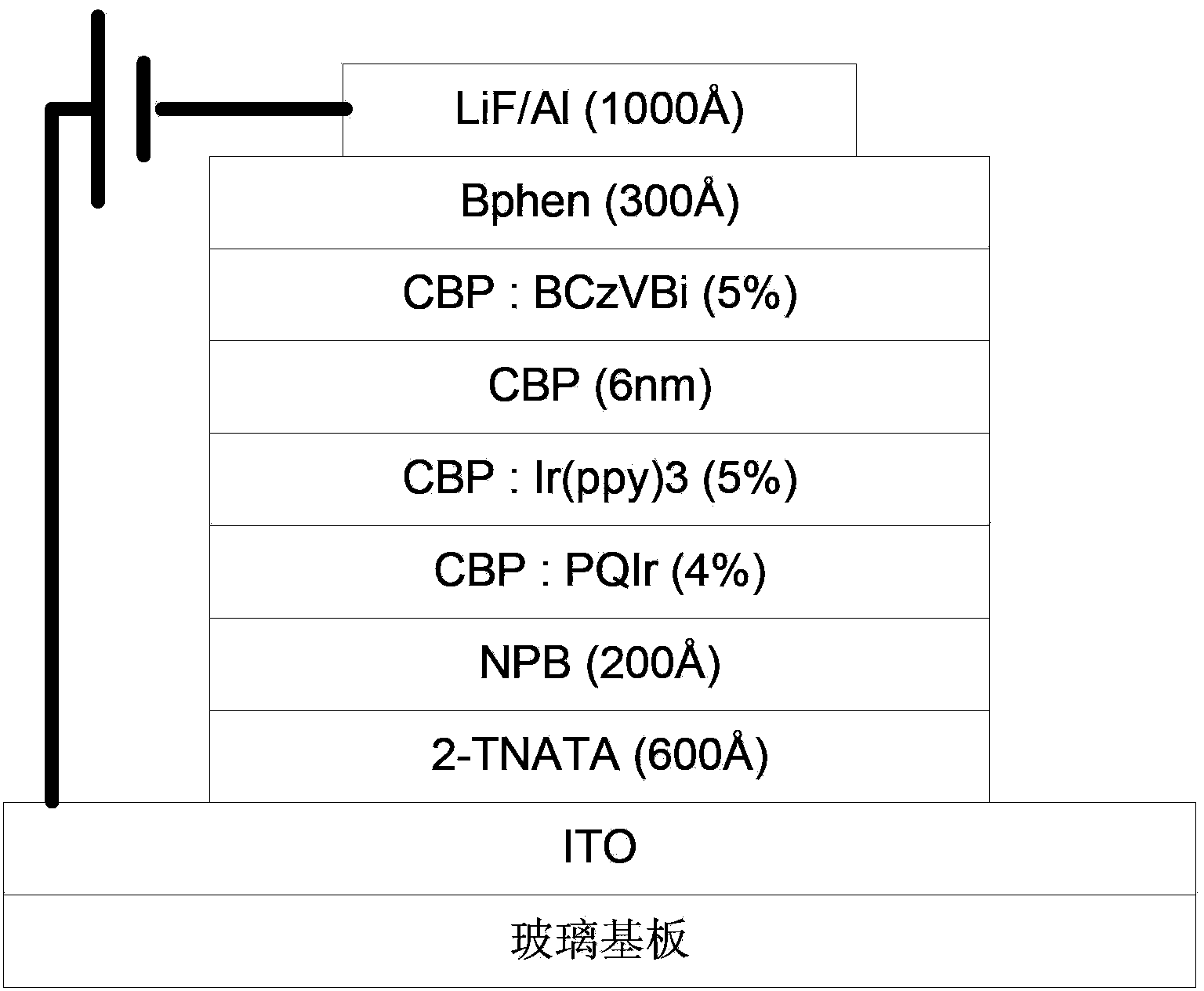

[0116] Organic electroluminescent device structure:

[0117] ITO / 2-TNATA(60nm) / NPB(20nm) / EMLR / EMLG-1 / Spacer(10nm) / EML-B / BPhen(30nm) / LiF(3nm) / Al(150nm)

[0118] Such as image 3 As shown, it is a cross-sectional view of the structure of Embodiment 1 of the present invention, which includes a substrate 10, an anode layer 20, a hole injection layer 30, a hole transport layer 40, a red phosphorescence emitting layer 50, a green phosphorescence emitting layer 60, and a barrier layer 70 , a blue fluorescent light-emitting layer 80 , an electron transport layer 90 , and a cathode layer 100 .

[0119] The preparation method of the organic light-emitting device is as follows:

[0120] ① Clean the ITO glass substrate that has been etched with a fixed pattern by using detergent ultrasonic and deionized water ultrasonic method, and place it under an infrared lamp to dry.

[0121] ②Place the above-mentioned treated glass substrate in the vacuum chamber, and evacuate to 1×10 -5 Pa, cont...

Embodiment 2

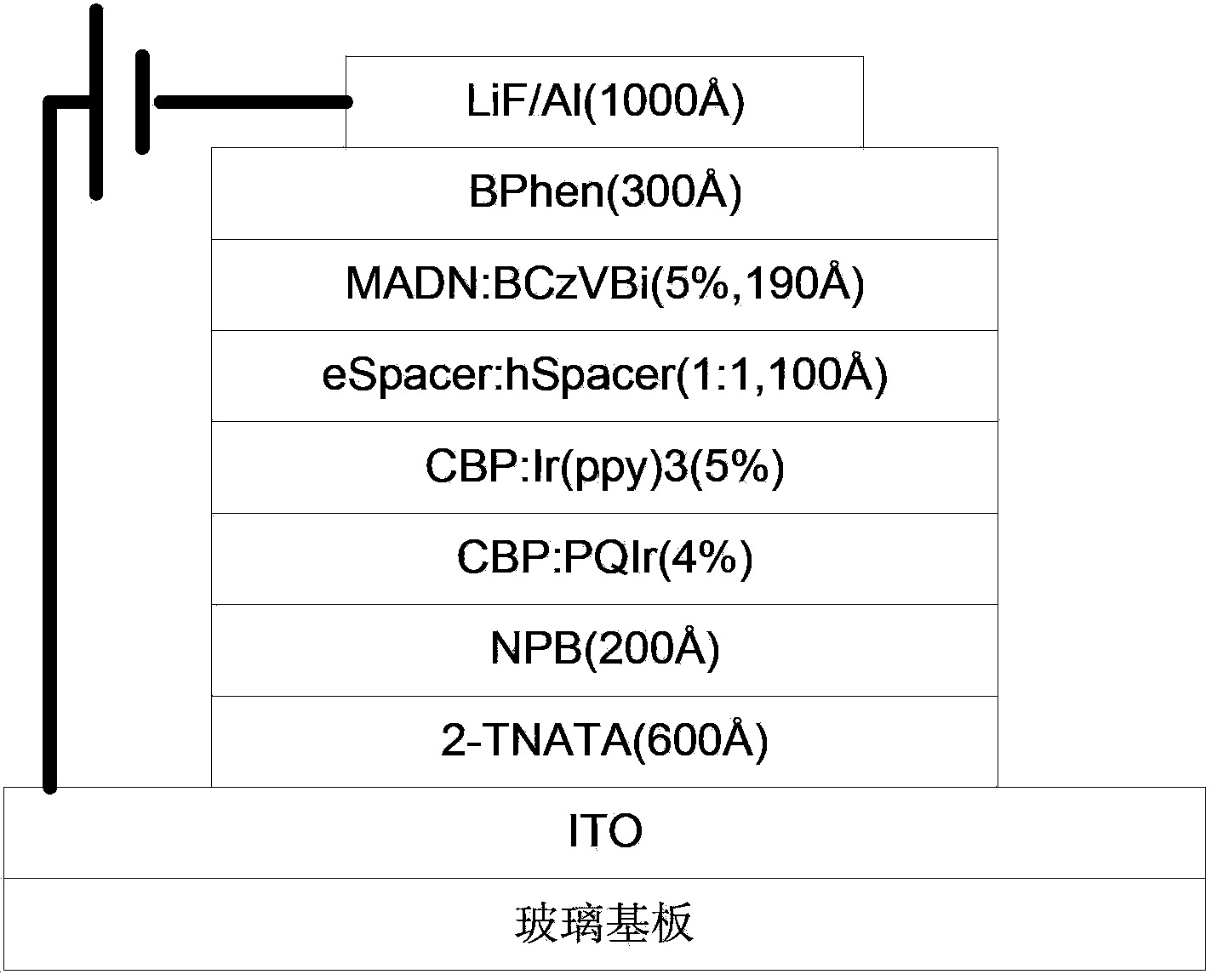

[0132] Organic electroluminescent device structure:

[0133] ITO / 2-TNATA(60nm) / NPB(20nm) / EML-R / EMLG-2 / Spacer(10nm) / EML-B / BPhen(30nm) / LiF(3nm) / Al(150nm)

[0134] The preparation method is the same as that in Example 1, except that the material of the green phosphorescence emitting layer in step ④ is replaced.

Embodiment 3

[0136] Organic electroluminescent device structure:

[0137] ITO / 2-TNATA(60nm) / NPB(20nm) / EML-B / Spacer(10nm) / EMLG-1 / EMLR / BPhen(30nm) / LiF(3nm) / Al(150nm)

[0138] The preparation method is the same as in Example 1, except that step ④ is changed to be implemented after step ⑥, and the evaporation sequence of the green phosphorescent layer is reversed with that of the red phosphorescent layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com